Process for preparing sludge autoclaved aerated concrete building block

A technology of concrete blocks and autoclaved gas filling, applied in the field of environmental engineering, can solve the problems of incomplete and effective treatment of harmful substances and affect the normal operation of sewage treatment plants, so as to protect cultivated land resources, eliminate the spread of epidemic diseases, The effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0028] First, the sludge with a water content of ≤85% in the sewage treatment plant is mixed evenly with quicklime, ferric chloride solution, and potassium permanganate, and then dried in a dryer, then pulverized by a ball mill, and sieved by a sieving machine for use. Among them, the mass percentages of raw materials are: 89.68% sludge, 10% quicklime, 0.2% ferric chloride solution, 0.12% potassium permanganate, the homogeneous mixture is aerobically digested for 8 hours, and the drying temperature of the dryer is 120 ° C ~ 160 ° C , After sieving with a 0.63mm sieving machine, the standby dried sludge is obtained.

PUM

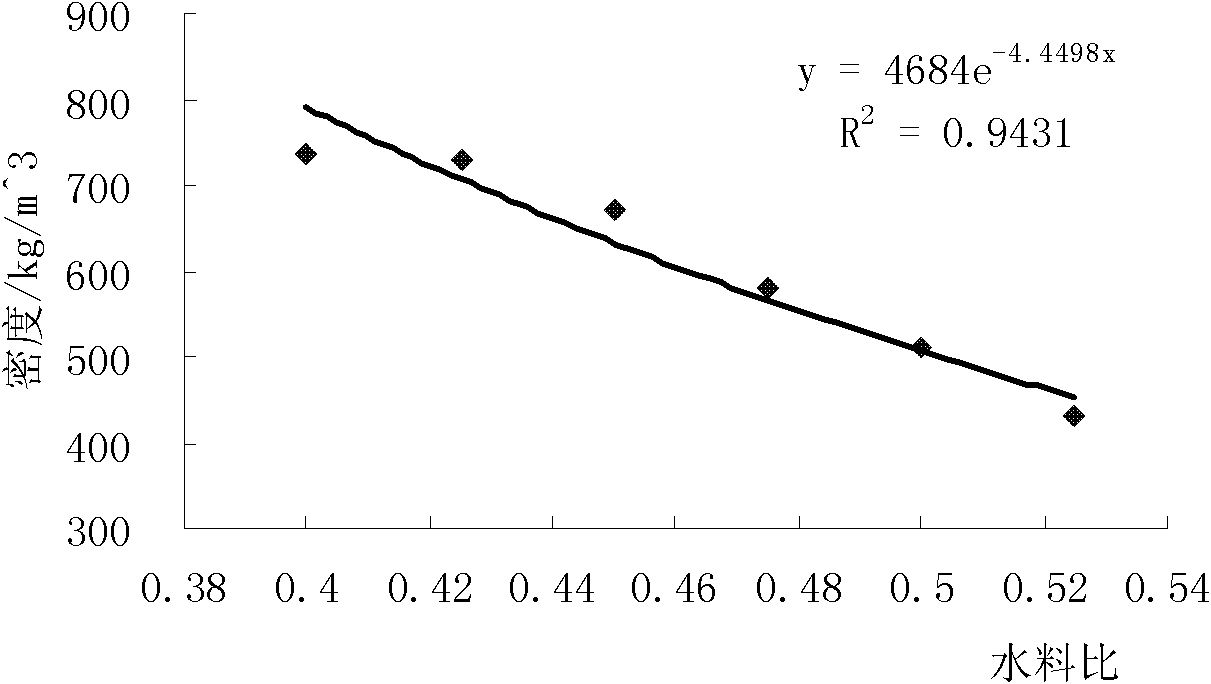

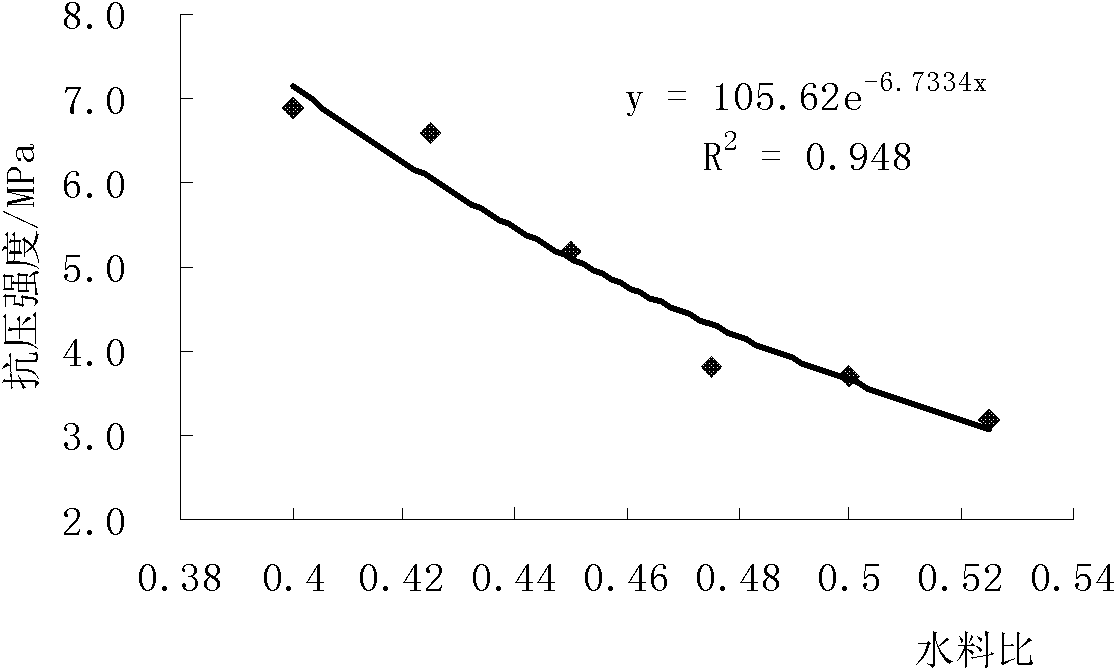

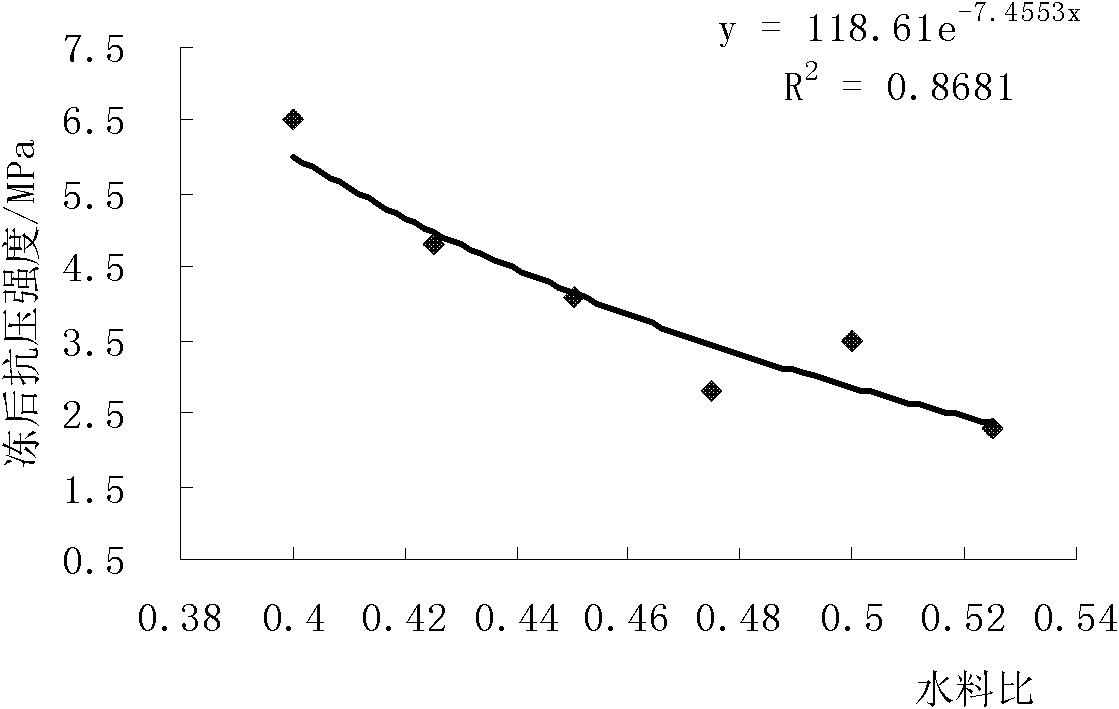

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com