Recycling method for zinc-containing waste residue and urban domestic sludge

An urban domestic sludge and recycling technology, applied in the field of resource utilization of zinc-containing waste residue and urban domestic sludge, can solve the problems of ineffective recovery, large equipment investment, complicated sludge incineration technology, etc. Simple ingredients, saving land resources, and significant environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

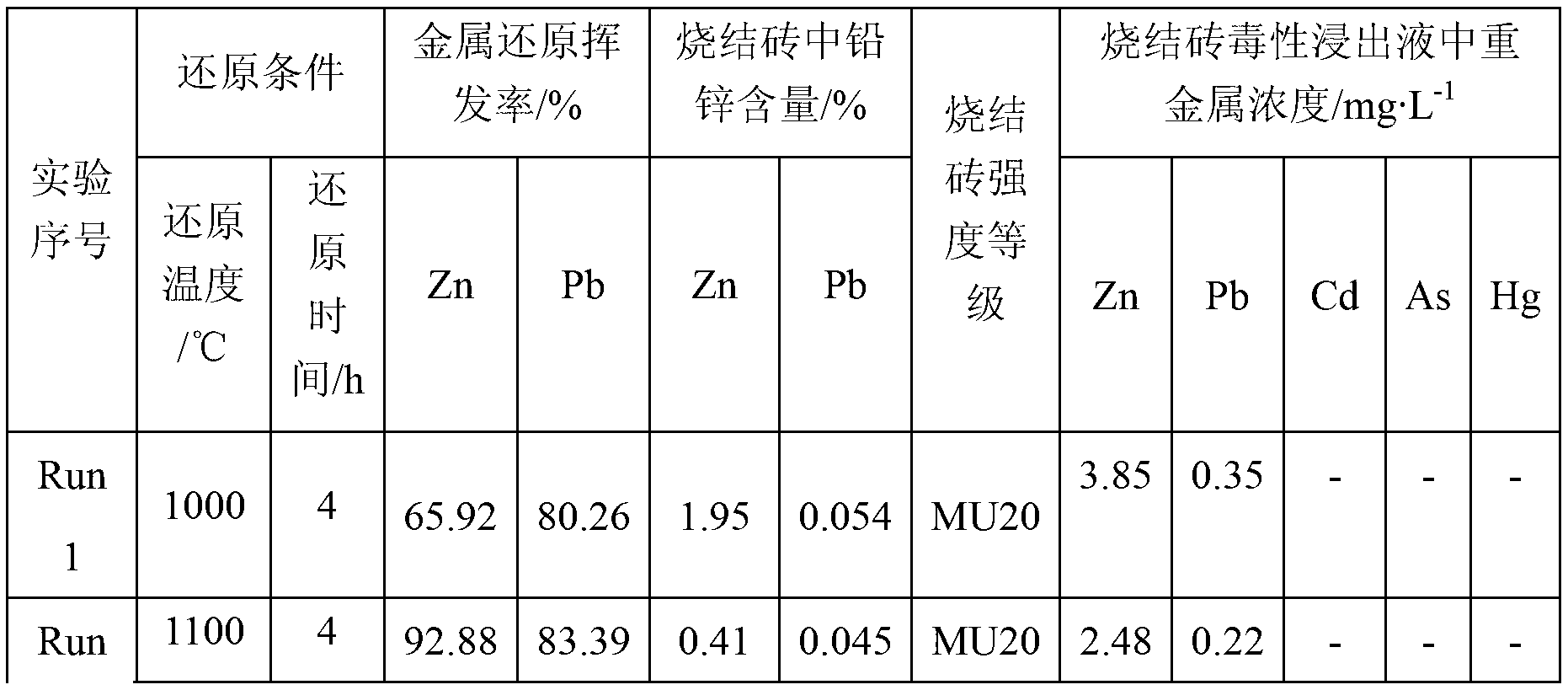

[0017] Example 1 Investigate the effect of reducing conditions on the properties of fired bricks

[0018] The zinc smelting waste slag used in the experiment is Guizhou native zinc smelting waste slag, which contains SiO 2 34.44%, T Fe 10.23%, Al 2 o 3 13.03%, T C 17%, Zn7.15%, Pb0.34%. Pass the crushed zinc smelting waste slag through a 2mm sieve for later use; mix 60% of the zinc smelting waste slag and 40% municipal domestic sludge, age at room temperature for 24 hours, and press to form under a pressure of 5 MPa; Dry the wet billet at 105°C for 8 hours to obtain a dry billet, place the dry billet in a high-temperature closed furnace for reduction and volatilization, the reduction temperature is 1000-1200°C, and the reduction time is 4-10 hours, and the volatile matter is collected to obtain zinc-rich fumes; Into the air for oxidation sintering, the oxidation temperature is 1000 ℃, and the oxidation time is 6h; cooling with the furnace to obtain the finished sintered b...

Embodiment 2

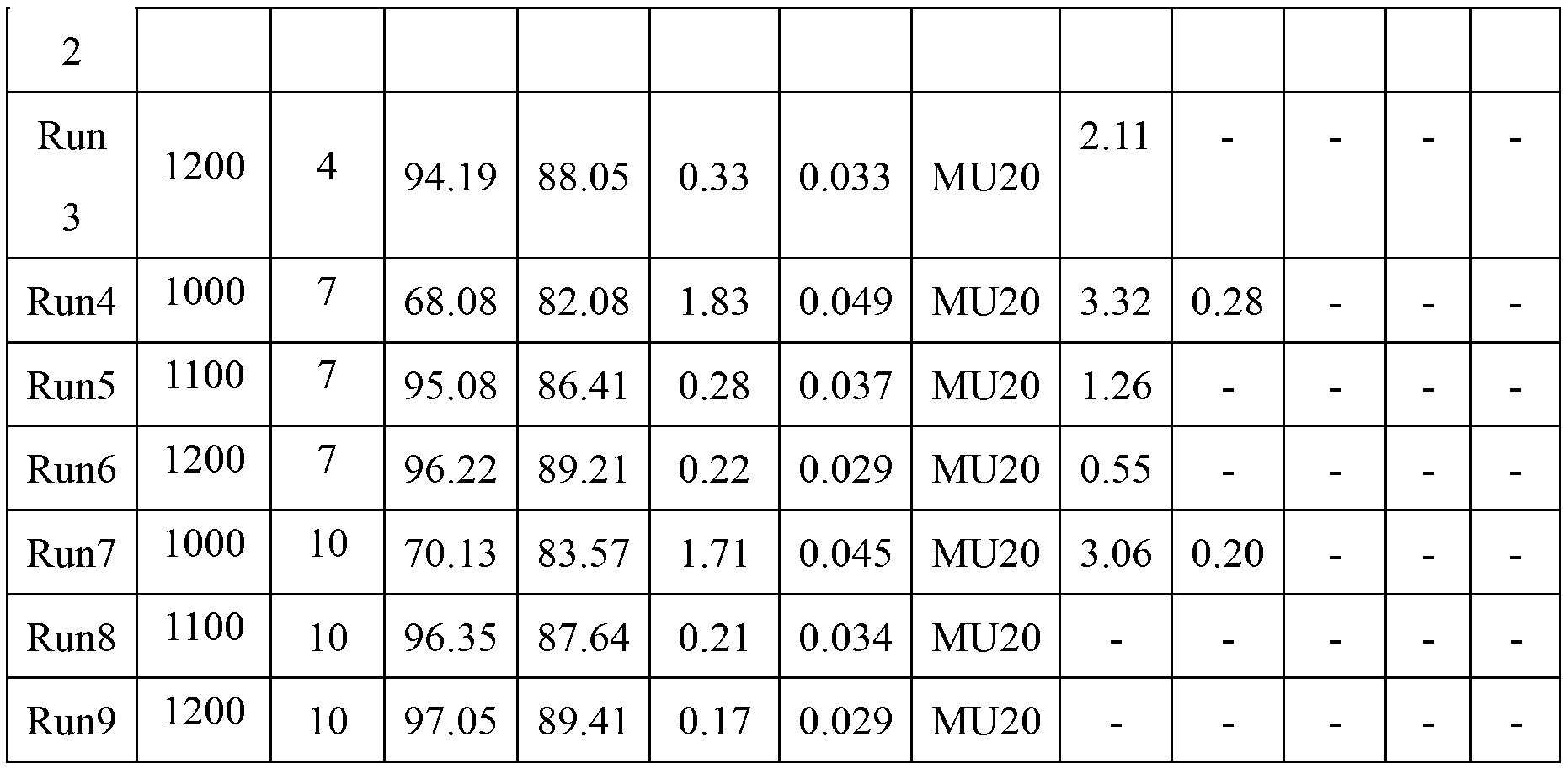

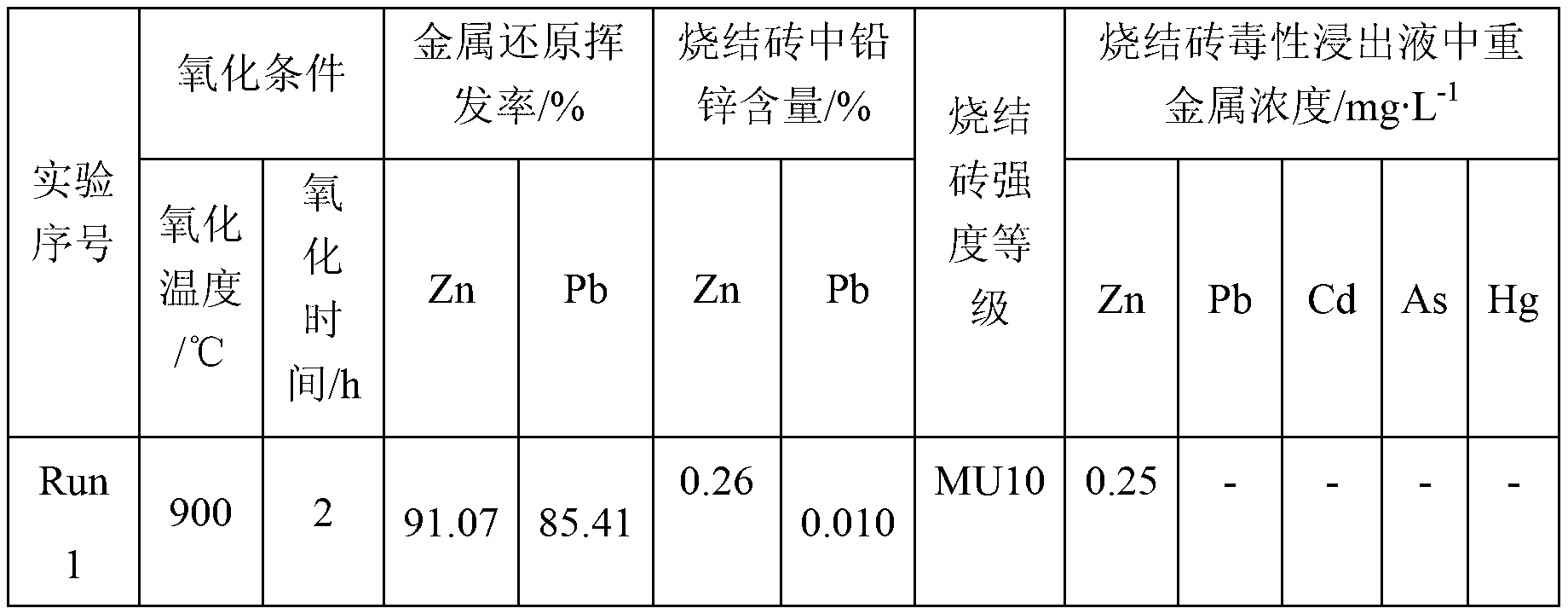

[0024] Example 2 Investigating the influence of oxidation conditions on the properties of fired bricks

[0025] The zinc smelting waste slag used in the experiment is Guizhou native zinc smelting waste slag, which contains SiO 2 43.01%, T Fe 8.57%, Al 2 o 3 16.73%, T C15.65%, Zn3.57%, Pb0.82%. Pass the crushed zinc smelting waste slag through a 2mm sieve for later use; mix 60% of the zinc smelting waste slag and 40% municipal domestic sludge, age at room temperature for 24 hours, and press to form under a pressure of 5 MPa; The wet billet is dried at 105°C for 8 hours to obtain a dry billet, which is reduced and volatilized in a high-temperature closed furnace. The reduction temperature is 1100°C and the reduction time is 8 hours. The volatile matter is collected to obtain zinc-rich smoke; The temperature is 900~1100℃, and the oxidation time is 2~8h; it is cooled with the furnace to obtain the finished sintered brick. According to the standard HJ / T299-2007 "Solid waste l...

Embodiment 3

[0031] Example 3 Investigate the effect of raw material ratio on the properties of fired bricks

[0032] The zinc smelting waste slag used in the experiment is Guizhou native zinc smelting waste slag, which contains SiO 2 23.91%, T Fe 14.86%, Al 2 o 3 9.58%, T C 20.8%, Zn1.28%, Pb0.55%. Crumble all the zinc smelting waste slag through a 2mm sieve and set aside; mix 80-40% of the zinc smelting waste slag and 20-60% urban sewage sludge and age at room temperature for 24 hours, Down compression molding; the wet billet was dried at 105°C for 8 hours to obtain a dry billet, and the dry billet was placed in a high-temperature closed furnace for reduction and volatilization, the reduction temperature was 1100°C, and the reduction time was 8 hours, and the volatile matter was collected to obtain zinc-rich fumes; Into the air for oxidation sintering, the oxidation temperature is 1000 ℃, and the oxidation time is 6h; cooling with the furnace to obtain the finished sintered brick. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com