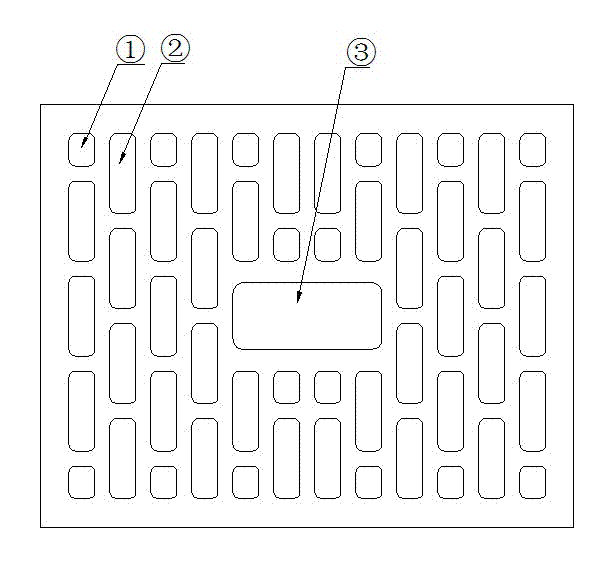

Preparation method of novel self-insulation perforated brick

A porous brick, self-insulation technology, applied in the field of building materials, can solve the problems of increasing the complexity of the production process and the cost of materials, high performance requirements for brick-making molds, and high product costs, and achieves market competitiveness. The effect of reducing the cost of brick making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0014] Specific example: According to illite shale: coal gangue: vitrified microbeads: additive mass ratio is 3:2:0.2:0.03 ingredients, mixed with water accounting for 10% of the total mass for aging, after 5 days into a double-stage vacuum The bricks are extruded by the extruder to form the bricks, and the bricks are dried in the drying section at 40±5°C for 72 hours, and the bricks are put into the wheel kiln and the temperature is slowly raised to 1000±10°C and kept for 7 hours. ~8 hours, so as to produce a new type of self-insulating porous brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com