Biogas slurry sintered brick and preparation method thereof

A technology of sintered bricks and biogas slurry, which is applied in the field of sintered bricks, can solve the problems of endangering people's health, polluting water sources and the environment, and low waste utilization rate, and achieves the effects of resource utilization, pollution reduction, and brick-making cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

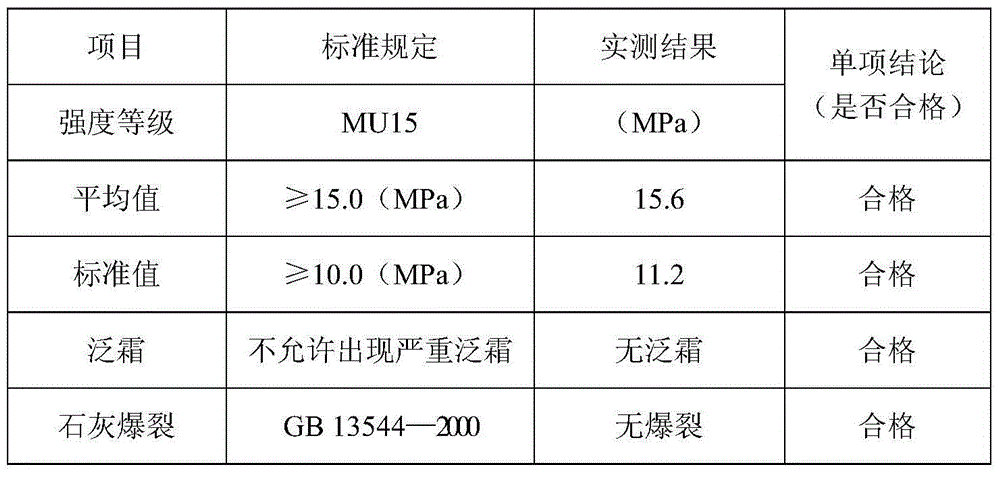

Embodiment 1

[0036] A biogas slurry sintered brick, the sintered brick is prepared from the following components by weight percentage: 80% clay, 19% coal gangue, 1% biogas slurry, the biogas slurry is anaerobic fermentation of organic matter in domestic garbage After generating biogas, the remaining waste is separated into liquid by solid-liquid separation.

[0037] A preparation method of biogas slurry sintered bricks, comprising the following steps:

[0038] (1) Raw material storage and pretreatment:

[0039] Weigh the following raw materials by weight percentage: 80% clay, 19% coal gangue, and 1% biogas slurry, and crush the clay and coal gangue using jaw crusher, hammer crusher, and finely crushed double-roller for three-stage crushing. After crushing, the particle size is less than 1.5mm, then add the biogas slurry, and stir with a twin-shaft mixer to make it evenly mixed;

[0040] (2) aging

[0041] Transporting the homogeneously mixed material mixture in step (1) to an aging ware...

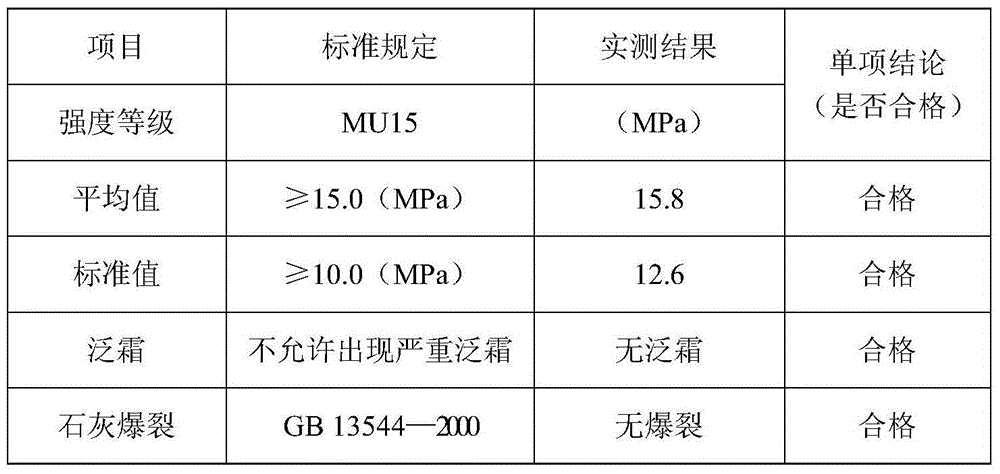

Embodiment 2

[0049] A biogas slurry sintered brick, the sintered brick is prepared from the following components in percentage by weight: clay 75.5%, coal gangue 24%, biogas slurry 0.5%, and the biogas slurry is anaerobic fermentation of organic matter in domestic waste After generating biogas, the remaining waste is separated into liquid by solid-liquid separation.

[0050] A preparation method of biogas slurry sintered bricks, comprising the following steps:

[0051] (1) Raw material storage and pretreatment:

[0052]Weigh the following raw materials by weight percentage: 75.5%, coal gangue 24%, biogas slurry 0.5%, crush the clay and coal gangue, and use jaw crusher, hammer crusher, fine crushing roller machine for three-stage crushing, crushing After the particle size is less than 1.5mm, then add the biogas slurry and stir with a twin-shaft mixer to make it evenly mixed;

[0053] (2) aging

[0054] Transporting the homogeneously mixed material mixture in step (1) to an aging warehous...

Embodiment 3

[0062] A biogas slurry sintered brick, the sintered brick is prepared from the following components in percentage by weight: clay 84%, coal gangue 14%, biogas slurry 2%, and the biogas slurry is organic matter in domestic garbage through anaerobic fermentation After generating biogas, the remaining waste is separated into liquid by solid-liquid separation.

[0063] A preparation method of biogas slurry sintered bricks, comprising the following steps:

[0064] (1) Raw material storage and pretreatment:

[0065] Weigh the following raw materials by weight percentage: 84%, coal gangue 14%, biogas slurry 2%, crush the clay and coal gangue, and use jaw crusher, hammer crusher, fine crushing roller machine for three-stage crushing, crushing After the particle size is less than 1.5mm, then add the biogas slurry and stir with a twin-shaft mixer to make it evenly mixed;

[0066] (2) aging

[0067] Transporting the homogeneously mixed material mixture in step (1) to an aging warehous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com