Baking-free green brick loading and unloading and transporting device matched with fork lift truck

A technology of transporting device and non-burning brick, applied in the direction of lifting device, etc., can solve the problems of high labor intensity, easy collision and damage, etc., and achieve the effect of high transportation efficiency, high brick-making yield and reducing brick-making cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

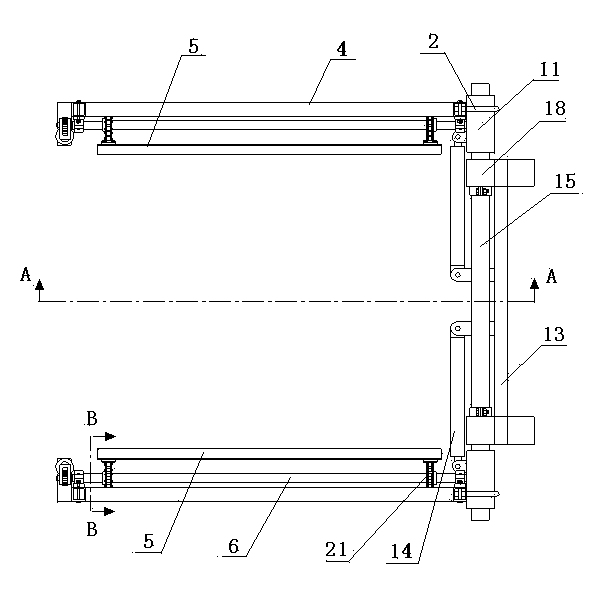

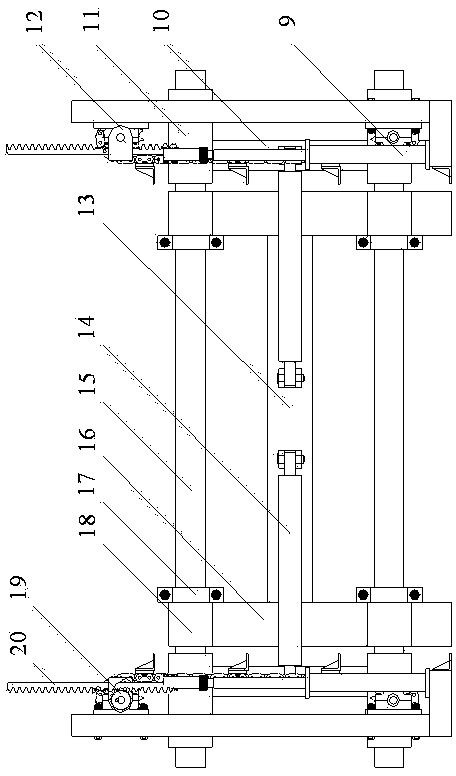

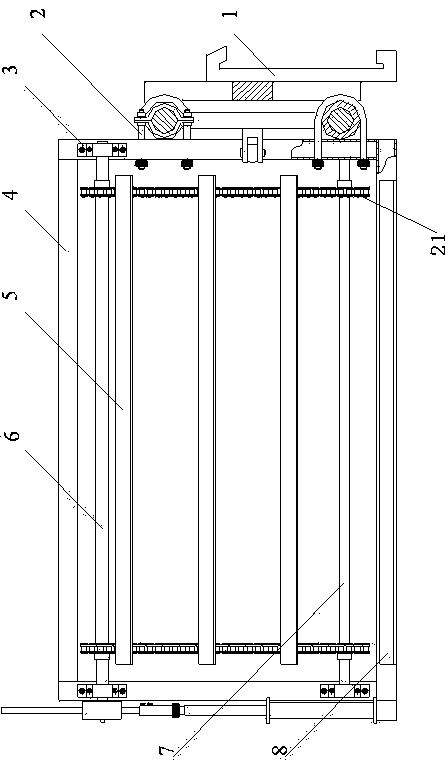

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] Such as figure 1 As shown, the non-burning adobe loading and unloading device matched with a forklift includes a main frame, a horizontal opening and closing assembly, a rack lifting assembly, a lifting chain assembly, and a side frame. The back of the frame is provided with a connecting beam fixed with the forklift fork frame. During work, the connecting beam 1 is installed on the forklift fork frame. In this embodiment, the horizontal opening and closing assembly, the rack lifting assembly, the lifting chain assembly, There are two sets of side frames, two sets of horizontal opening and closing assembly, rack lifting assembly, lifting chain assembly, and side frames are symmetrically arranged, and two sets of side frames are symmetrically arranged on both sides of the main frame.

[0025] refer to figure 2 As shown, there are two sets of transverse opening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com