Microbial fuel cell taking straws and sludge as matrixes, construction method and sludge treatment method

A technology of fuel cell and construction method, applied in the direction of biological sludge treatment, biochemical fuel cell, etc., can solve the problems of poor sludge treatment effect, achieve the effects of reduced incineration energy consumption, easy transportation and handling, and improved processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

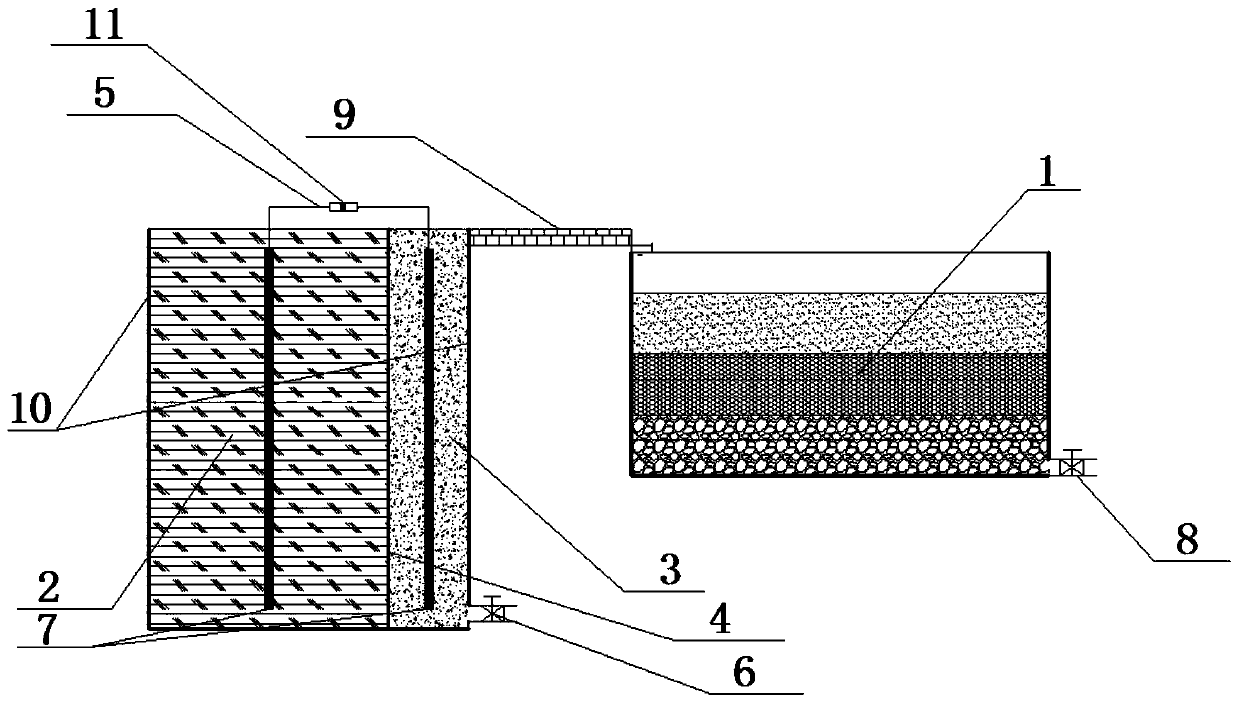

[0032]A straw and sludge-based microbial fuel cell of the present invention, as shown in FIG. 2 , includes an anode chamber 200 , a cathode chamber 300 , a proton exchange membrane 400 and a circuit system 500 . The matrix of the anode chamber 200 is a stirred mixture of straw and sludge with a mass ratio of 0.5-2:1, which is used to provide acceptors for bacteria to transfer electrons. The matrix of the cathode chamber 300 is sludge, which is used to receive electrons and form an electric current through an external circuit. The stalks used in the anode chamber 200 are strip-shaped hollow plant stalks, and the silt used in the anode chamber 200 and the cathode chamber 300 has a water content of 60% to 98%. The invention does not need to control the temperature, pH and water content, and the straw and the sludge have a mass ratio relationship, and it is enough to stir evenly. It is worth noting that the volume ratio of the anode chamber 200 and the cathode chamber 300 is 2-5:...

Embodiment 2

[0073] The basic content of this embodiment is the same as that of Embodiment 1, the difference lies in the adjustment of actual application parameters. For example, during the dredging project of a black and odorous river course in a certain city, about 100t of silt was urgently needed to be disposed of (with a density of approximately 1t / m 3 ), the water content of the silt is 90%, and the regional water environment quality standard must meet the Class IV water standard in the "National Surface Water Quality Standard" (GB3838-2002). In addition, the depth of the groundwater in the area reaches 3m (the groundwater level is low), so this project prevents the seepage of groundwater, and the height of the microbial fuel cell is set at 2m.

[0074] Calculate the size of the microbial fuel cell in terms of 20m 3 As a unit sludge disposal device, it is divided into 5 groups.

[0075] Ratio of main parameters: aspect ratio 2:1, anode chamber 200 volume and cathode chamber 300 volu...

Embodiment 3

[0086] The basic content of this embodiment is the same as that of Embodiment 1, the difference lies in the adjustment of actual application parameters. For example, in a city’s black and odorous river improvement project, about 150 tons of silt was urgently needed to be disposed of during the dredging project (with a density of approximately 1t / m 3 ), the water content of the silt is 90%, and the regional water environment quality standard must meet the Class IV water standard in the "National Surface Water Quality Standard" (GB3838-2002). In addition, the depth of groundwater in the area reaches 6m, so this project prevents the seepage of groundwater, and the height of the microbial fuel cell is set at 5m.

[0087] Calculate the size of the microbial fuel cell in terms of 30m 3 As a unit sludge disposal device, it is divided into 5 groups.

[0088] Ratio of main parameters: aspect ratio 3:1, anode chamber 200 volume and cathode chamber 300 volume ratio 3:1.

[0089] Thus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com