A method for firing sponge bricks using sludge and silt

A technology of sponge bricks and silt, applied in the field of building materials, can solve the problems of limited use of clay materials, high cost and other problems, and achieve the effects of high strength, resource saving and smooth surface of bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method of using sludge and sludge to make sponge bricks, the steps are as follows:

[0028] S1. Stir the sludge, sludge and cement at a speed of 300r / min for 5 minutes; add water glass to the mixture and continue to stir at the same speed for 10 minutes;

[0029] S2. Send the evenly stirred mixture into the brick making machine and press it into bricks;

[0030] S3, curing the obtained green body at room temperature for 3 days, and putting the green body in a drying room for 12 hours, the temperature of the drying room is 100°C;

[0031] S4. During the roasting process of the dried green body, the temperature is set to 1050℃, and the organic matter in the sludge is completely burned out after sintering for 6 hours; the sponge brick is made.

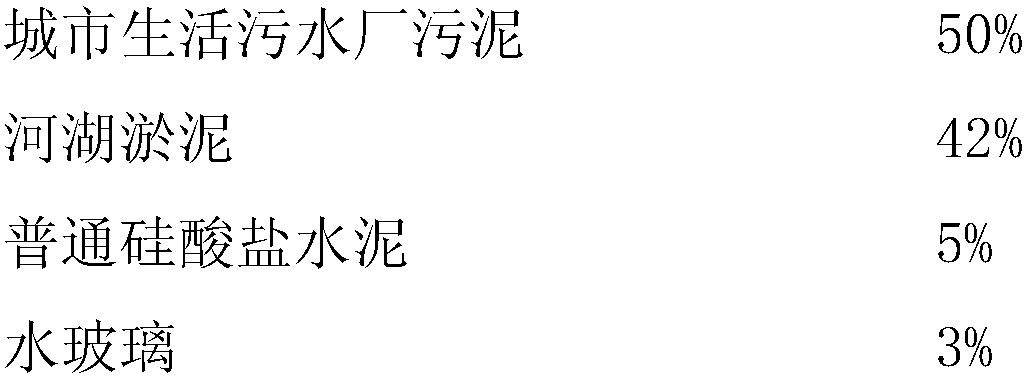

[0032] Among them, the mass fraction of each ingredient (wet weight) is:

[0033]

[0034] The water content of urban domestic sludge is 81%, and the water content of sludge is 65%.

[0035] Ordinary Portland cement is labeled OPC32.5.

[003...

Embodiment 2

[0041] A method of using sludge and sludge to make sponge bricks, the steps are as follows:

[0042] S1. Stir the sludge, sludge and cement at a speed of 350r / min for 6 minutes; add water glass to the mixture and continue to stir at the same speed for 12 minutes;

[0043] S2. Send the evenly stirred mixture into the brick making machine and press it into bricks;

[0044] S3, curing the obtained green body at room temperature for 3 days, and putting the green body in a drying room for 12 hours, the temperature of the drying room is 100°C;

[0045] S4. During the roasting process of the dried green body, the temperature is set to 1050℃, and the organic matter in the sludge is completely burned out after sintering for 6 hours; the sponge brick is made.

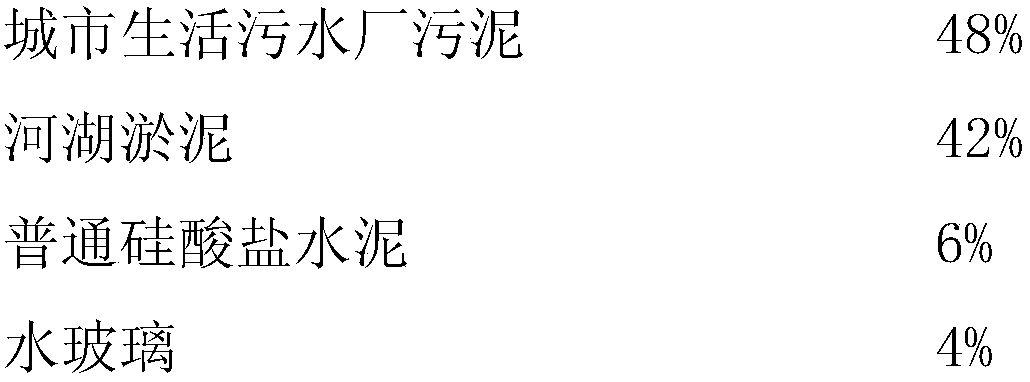

[0046] Among them, the mass fraction of each ingredient (wet weight) is:

[0047]

[0048] The water content of urban domestic sludge is 72%, and the water content of sludge is 62%.

[0049] Ordinary Portland cement is labeled OPC32.5.

[005...

Embodiment 3

[0055] A method of using sludge and sludge to make sponge bricks, the steps are as follows:

[0056] S1. Stir the sludge, sludge, and cement at a speed of 350r / min for 8 minutes; add water glass to the mixture and continue to stir at the same speed for 15 minutes;

[0057] S2. Send the evenly stirred mixture into the brick making machine and press it into bricks;

[0058] S3, curing the obtained green body at room temperature for 3 days, putting the green body in a drying chamber for 12 hours, and the temperature of the drying chamber is 98°C;

[0059] S4. During the roasting process of the dried green body, the temperature is set to 1050°C, and the organic matter in the sludge is completely burned out after 8 hours of sintering; the sponge brick is made.

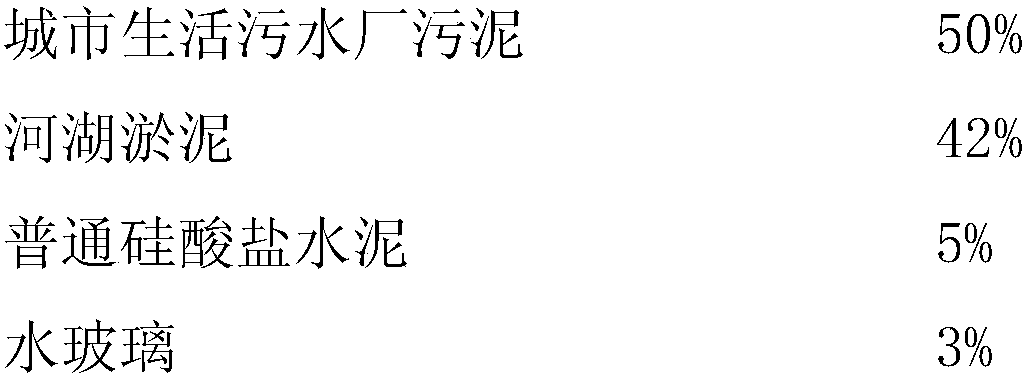

[0060] Among them, the mass fraction of each ingredient (wet weight) is:

[0061]

[0062] The water content of urban domestic sludge is 81%, and the water content of sludge is 65%.

[0063] Ordinary Portland cement is labeled OPC32.5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com