Method for making cement bricks by using pulping alkali to recover green mud and boiler ash

A boiler ash and cement brick technology, applied in the field of cement brick production, can solve the problems of high energy consumption, inability to realize maximum utilization of waste, and low green mud consumption, so as to save cement expenses, improve waste utilization rate, and save The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

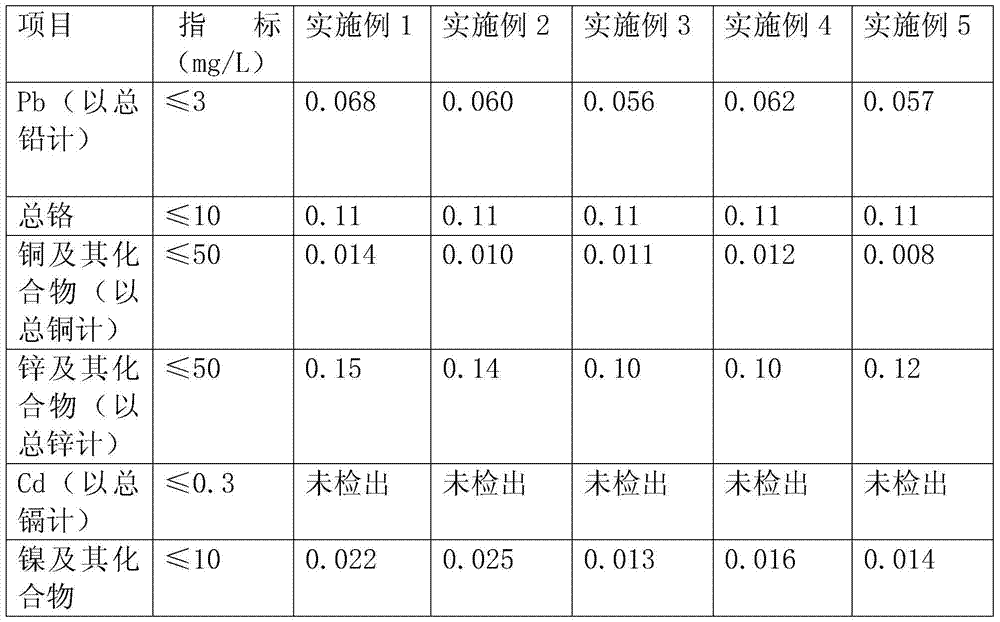

Examples

Embodiment 1

[0023] 1) Weigh the following raw materials in weight percentage: 25% of green mud, 19% of boiler ash, 55% of stone powder and 1% of ordinary Portland cement, and mix the above raw materials to obtain a mixture;

[0024] The water content of described green mud is 70%, and NaOH and Ca(OH) in the green mud 2 The weight content is 4%; The content of fly ash in the boiler ash is 80%, and the slag content is 20%; NaOH and Ca(OH) 2 The weight ratio is 2:1.

[0025] 2) Molding the mixture under a pressure of 40 MPa to obtain bricks.

[0026] 3) Curing the adobe for 28 days to obtain cement bricks.

Embodiment 2

[0028] 1) Weigh the following raw materials in weight percentage: 28% of green mud, 18% of boiler ash, 52.8% of stone powder and 1.2% of ordinary Portland cement, and mix the above raw materials to obtain a mixture;

[0029] The water content of described green mud is 80%, and NaOH and Ca(OH) in the green mud 2 The weight content is 5%; The content of fly ash in the boiler ash is 90%, and the slag content is 10%; NaOH and Ca(OH) 2 The weight ratio is 1:1.

[0030] 2) molding the mixed material under a pressure of 50 MPa to obtain adobe.

[0031] 3) Curing the adobe for 28 days to obtain cement bricks.

Embodiment 3

[0033] 1) Weigh the following raw materials in weight percentage: 26% of green mud, 38% of boiler ash, 35% of stone powder and 1% of ordinary Portland cement, and mix the above raw materials to obtain a mixture;

[0034] The water content of described green mud is 75%, and NaOH and Ca(OH) in green mud 2 The weight content is 4.5%; NaOH and Ca(OH) 2 The weight ratio is 1:2.

[0035] The fly ash content in the boiler ash is 80%, and the slag content is 20%.

[0036] 2) Molding the mixture under a pressure of 45 MPa to obtain bricks.

[0037] 3) Curing the adobe for 28 days to obtain cement bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com