Production process and production equipment of sludge and garbage carbonized slurry fuel

A waste carbonization pulp and production process technology, applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of complex process technology, difficult promotion and use, high production cost, etc., achieve short process flow, low power consumption per ton, The effect of high equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

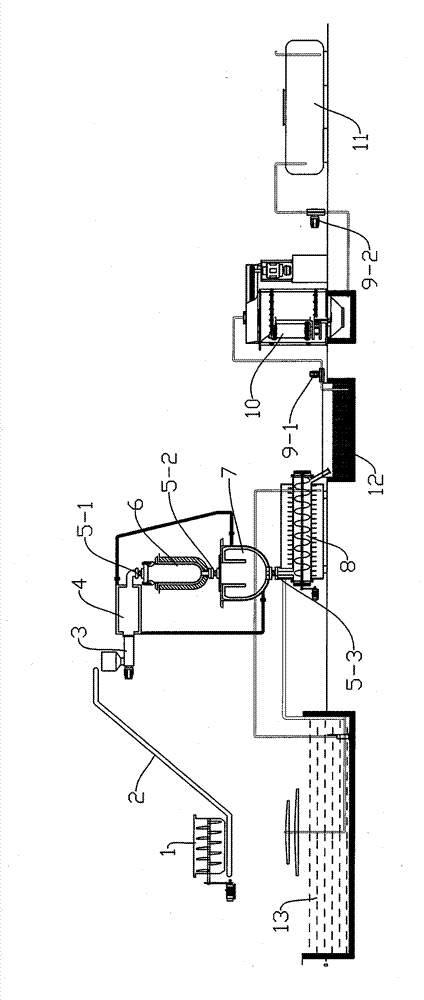

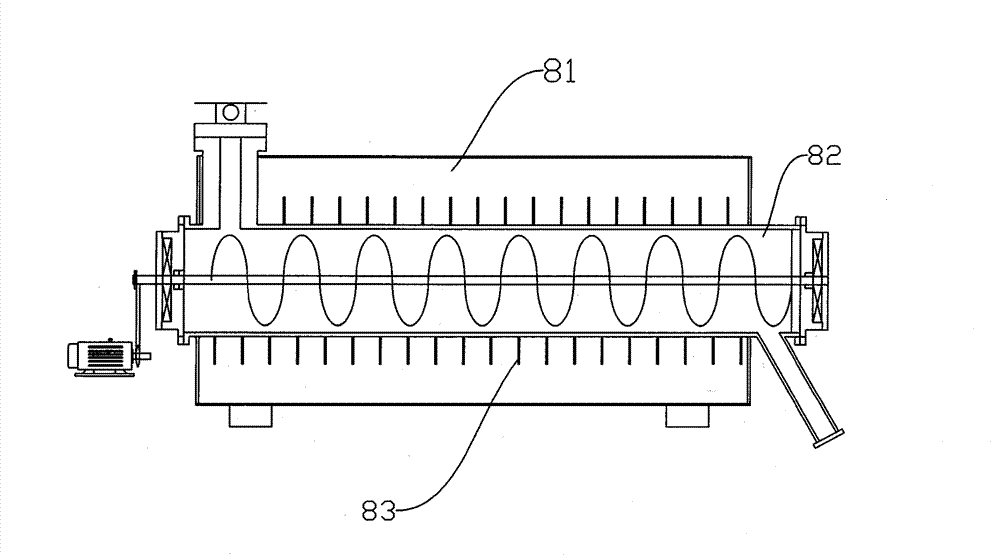

[0020] In this embodiment, the production equipment of the present invention includes a material agitator 1, a horizontally arranged high-pressure feed pump 3 and a jacketed preheating chamber 4, and a vertically arranged carbonization chamber connected to the outlet of the preheating chamber 4. The reaction kettle 6 is provided with a first electric control valve 5-1 at the outlet of the preheating chamber 4, and a decompression switch with an inner and outer jacket is connected to the carbonization reaction kettle 6 through the second electric control valve 5-2. Heater 7, the decompression heat exchanger 7 is connected to a spiral cooling device 8 through the third electronically controlled valve 5-3, and the spiral cooling device 8 is provided with a delivery pipeline leading to a mixing tank 12; the mixing tank passes through the pipeline The first slurry pump 9-1 is connected with the vertical planetary mill 10, and the vertical planetary mill 10 is connected with the seco...

Embodiment 2

[0026] In this embodiment, in order to further improve the production efficiency of the present invention, when setting up the production equipment system, a larger-volume decompression heat exchanger can be set up, and then two sets of separate preheating chambers and carbonization kettles can be set up. A separate set of preheating chambers and carbonization kettles are connected to this decompression heat exchanger. In this way, during production, the two sets of preheating bins and carbonization kettles can alternately feed and discharge materials, making the process smooth, making full use of the space of the equipment, and improving production efficiency.

[0027] In this embodiment, in the process steps of mixing, pressurizing, and preheating: the mixed material is heated to 200 degrees Celsius by the high-temperature steam in the bulkhead jacket in the preheating chamber.

[0028] In the high-pressure carbonization step: the carbonization kettle is preheated to 315 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com