Comprehensive treatment method for mine tailing

A technology for comprehensive treatment and tailings, applied in the field of comprehensive treatment of tailings, can solve the problems of unsatisfactory comprehensive treatment effect, high cost of making bricks from tailings, and potential safety hazards, so as to reduce the input of new products, save resources, and achieve product safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

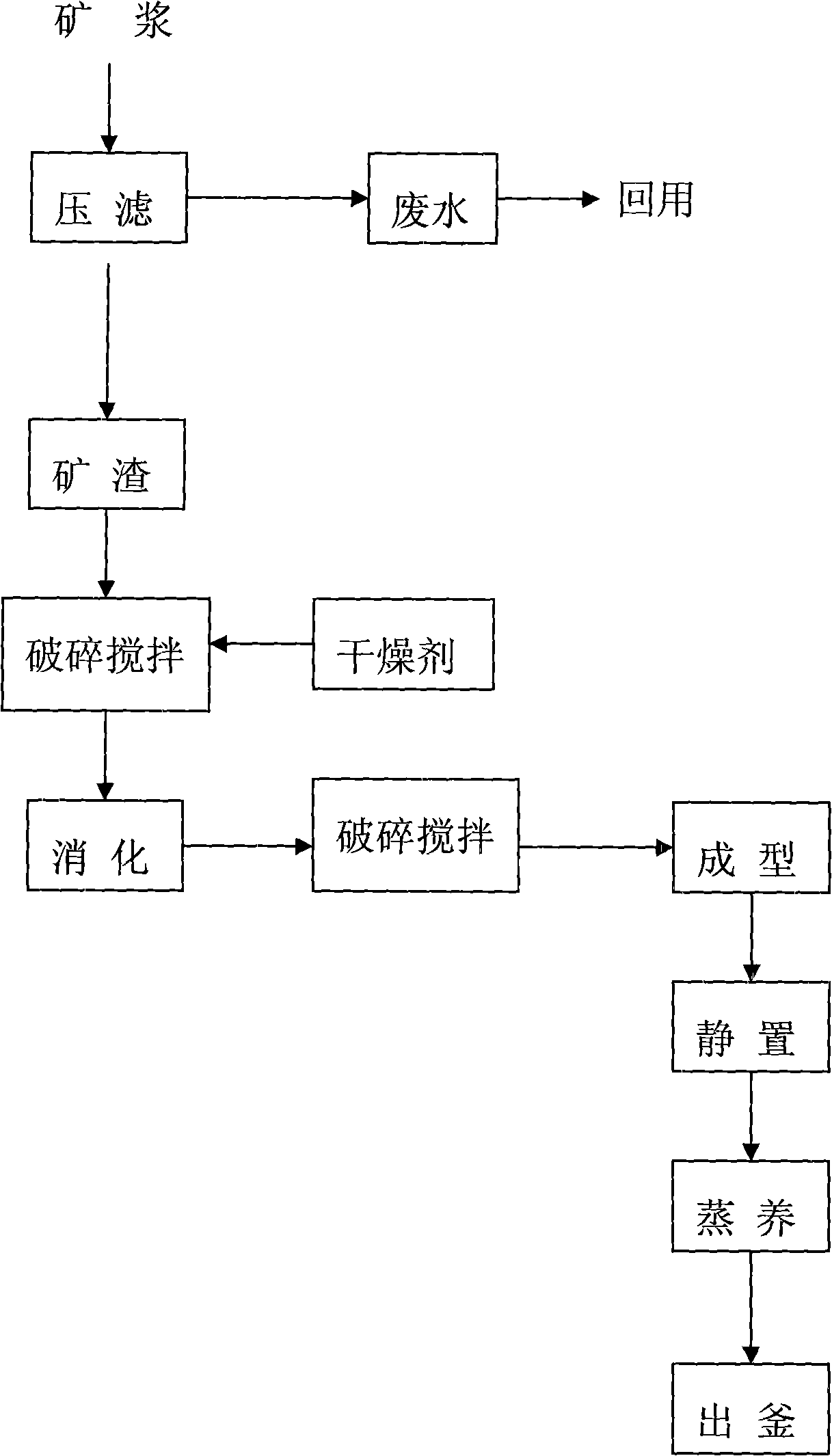

[0029] 1. Pulp treatment: Copper ore pulp is divided into waste water and slag by pressure filtration. The waste water contains a large amount of cyanide, which is refluxed in a closed way for secondary use in the beneficiation workshop. Zero discharge is achieved. The water content of the slag is about 18%. Not suitable for making bricks directly.

[0030] 2. Slag pretreatment: Add 12 parts of cement and 38 parts of sand to 50 parts of slag, crush and stir, put it into the digestion bin for 2 hours. At this time, the water content of the slag reaches about 10%, which meets the requirements of brick making, and the residual sodium cyanide volatilizes automatically in the process.

[0031] 3. Brick making: After the secondary crushing and stirring, put it into the wheel mill and mix evenly, and then form it, rest in the room for 3 hours, put it into the steam curing kettle for steam curing (about 194°C) for 8 hours, and then leave the kettle. A small amount of residual sodium ...

Embodiment 2

[0033] One, pulp treatment: with embodiment 1.

[0034] 2. Slag pretreatment: Add 10 parts of cement, 30 parts of sandstone and 0.5 part of water glass to 65 parts of slag, crush and stir, and put it into the digestion bin for digestion for 3 hours.

[0035] 3. Brick making: after the secondary crushing and stirring, put it into the wheel mill and mix evenly, and then shape it (standard brick or blind hole brick), rest in the room for 2 hours, and put it in a steam curing kettle for steam curing (about 194°C) 6h, take out the kettle.

[0036] The steam-cured brick made of copper ore slag completely decomposes the residual sodium cyanide in the tailings by adding water glass and cement and undergoing high-pressure steam curing. The products have passed the tests of Shangluo City Product Quality Supervision and Inspection Institute and Xi'an University of Architecture and Technology for flexural resistance, compression resistance, radioactivity and sodium cyanide removal experi...

Embodiment 3

[0038] 1. Pulp treatment: The gold mine pulp is separated into waste water and slag by pressure filtration. The waste water contains a large amount of cyanide, which is refluxed in a closed way for secondary use in the beneficiation workshop, achieving zero discharge.

[0039] 2. Slag pretreatment: Add 12 parts of cement and 28 parts of sand to 60 parts of slag, crush and stir, put it into the digestion bin for 2 hours.

[0040] 3. Brick making: After the secondary crushing and stirring, put it into the wheel mill and mix evenly, and then shape it (blind hole brick), rest in the room for 1.5 hours, put it into the steam curing kettle for 8 hours, and leave the kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com