Ore muck separation system

A separation system and ore slag technology, applied in the field of cement, concrete aggregate and artificial sand production, can solve the problems of occupying land and environmental pollution of slag, and achieve the effect of comprehensive utilization and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

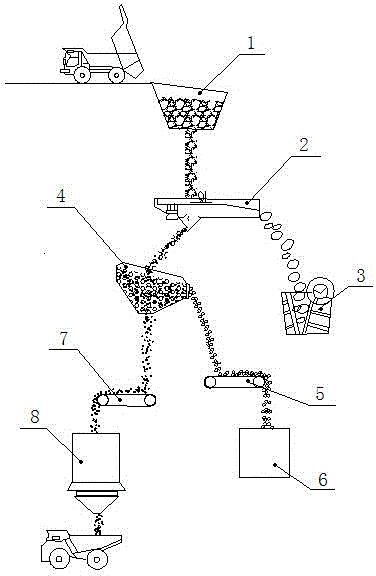

[0009] figure 1 Shown is the structural representation of the present invention.

[0010] The invention provides a system for separating ore and slag soil, comprising a material pool 1, a rod feeder 2, a crusher 6 is arranged at the outlet of the rod feeder 2, and the rod of the rod feeder 2 A screening device 4 is provided at the funnel below the bar screen surface, and a belt conveyor I5 is provided at the outlet of the screening device 4, and an aggregate bin 6 is provided at the discharge end of the belt conveyor I5; the screen surface of the screening device 4 The outlet below is provided with a belt conveyor II7, and the discharge end of the belt conveyor II7 is provided with a muck bin 8.

[0011] Process of the present invention is as follows:

[0012] After the stripped stone produced in the ore mining is put into the material pool 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com