New process for wastewater recycling comprehensive treatment in alga processing

A technology for processing wastewater and comprehensive treatment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve good treatment effect, expand the scope, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

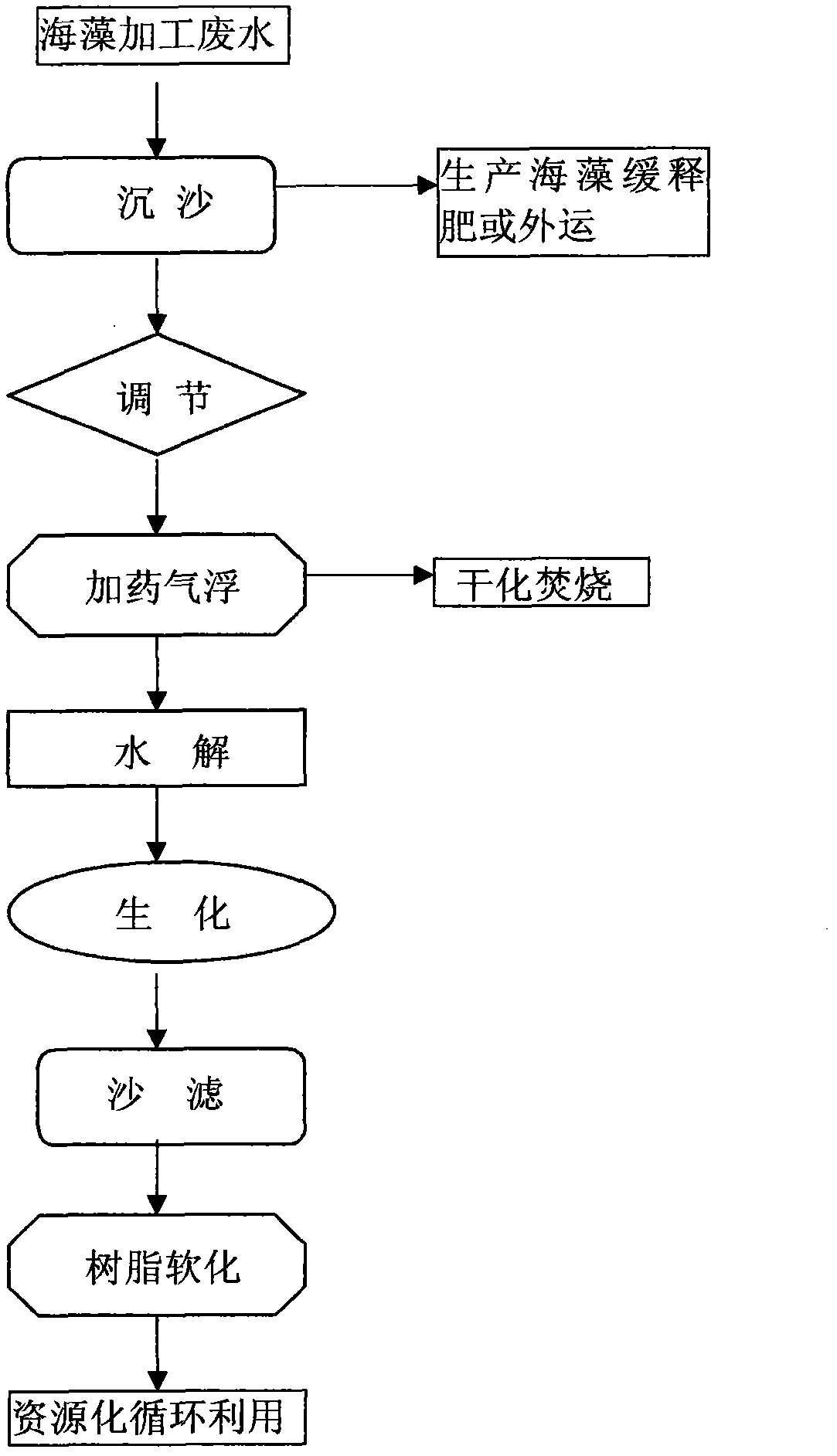

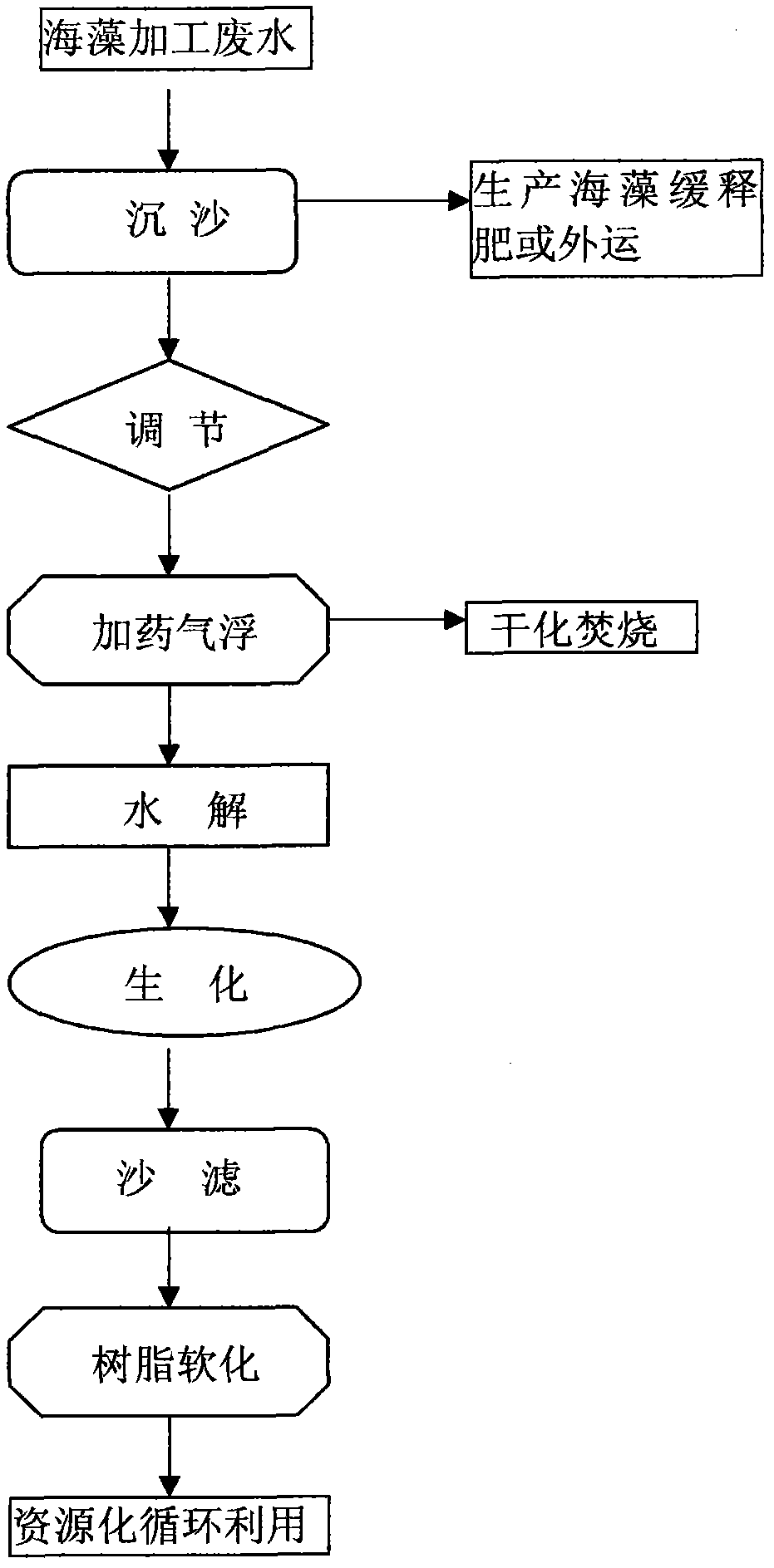

Image

Examples

Embodiment 1

[0054] (1) sinking sand

[0055] The seaweed processing wastewater is naturally settled in the sand settling tank, and the sand is set for 1 hour to remove large suspended solids and impurities such as seaweed residue, chemical fiber, and sand, and the seaweed residue is used to produce seaweed slow-release fertilizer or shipped out.

[0056] (2) adjustment

[0057] The wastewater after sedimentation is pumped into the regulating tank, and the wastewater is mixed when the regulating tank is full to adjust the water quality to ensure that the wastewater is evenly mixed.

[0058] (3) Dosing air flotation

[0059] After the water quality is stabilized, the waste water is pumped into the vortex concave aeration air flotation machine, and the concentration of 12% Cacl is passed through the pipeline. 2 The solution is added to the air flotation machine, and then the polyacrylamide solution with a concentration of 2‰ is added to the air flotation machine through the pipeline, Cacl ...

Embodiment 2

[0071] (1) sinking sand

[0072] The seaweed processing wastewater is naturally settled in the sand settling tank, and the sand is settled for 0.5 hours to remove large suspended solids and impurities such as seaweed residue, chemical fiber, and sand, and the seaweed residue is used to produce seaweed slow-release fertilizer or shipped out.

[0073] (2) adjustment

[0074] The wastewater after sedimentation is pumped into the regulating tank, and the wastewater is mixed when the regulating tank is full to adjust the water quality to ensure that the wastewater is evenly mixed.

[0075] (3) Dosing air flotation

[0076] After the water quality is stabilized, the waste water is pumped into the vortex concave aeration air flotation machine, and the concentration of 5%% Cacl is passed through the pipeline. 2 The solution is added to the air flotation machine, and then the polyacrylamide solution with a concentration of 2‰ is added to the air flotation machine through the pipeline...

Embodiment 3

[0088] (1) sinking sand

[0089] The seaweed processing wastewater is naturally settled in the sand settling tank, and the sand is set for 1 hour to remove large suspended solids and impurities such as seaweed residue, chemical fiber, and sand, and the seaweed residue is used to produce seaweed slow-release fertilizer or shipped out.

[0090] (2) adjustment

[0091] The wastewater after sedimentation is pumped into the regulating tank, and the wastewater is mixed when the regulating tank is full to adjust the water quality to ensure that the wastewater is evenly mixed.

[0092] (3) Dosing air flotation

[0093] After the water quality is stabilized, the waste water is pumped into the vortex concave aeration air flotation machine, and the concentration of 10% Cacl is passed through the pipeline. 2 The solution is added to the air flotation machine, and then the polyacrylamide solution with a concentration of 2‰ is added to the air flotation machine through the pipeline, Cacl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com