Graphene, production method and use thereof and battery

A production method and graphene technology, applied in the field of graphene, can solve the problems of alleviating pollution, high metal impurity content in graphene, large amount of sewage, etc., so as to reduce manganese content, save washing water consumption, reduce sewage treatment amount and environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

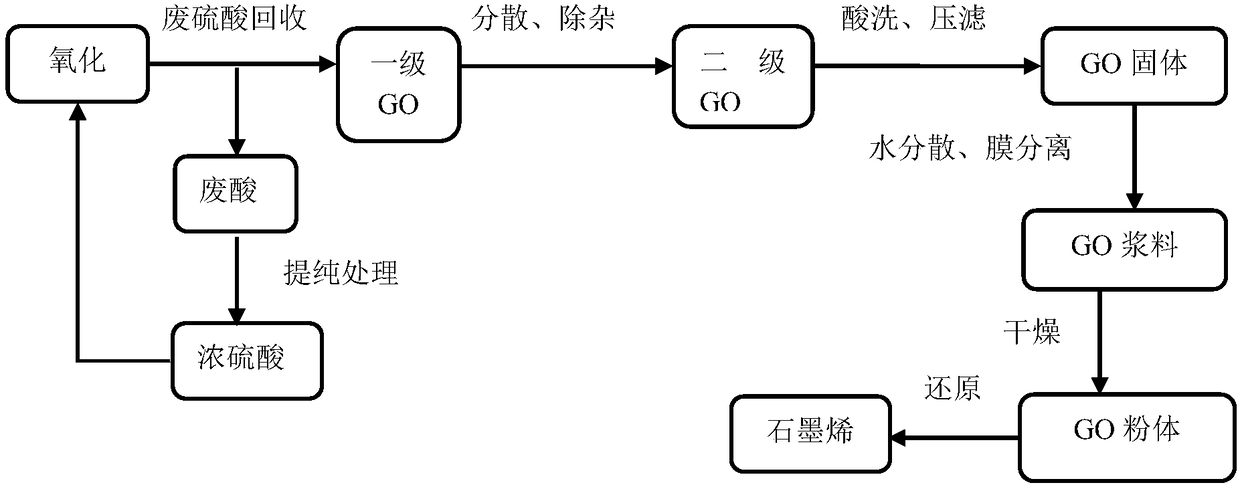

[0047] Present embodiment is a kind of production method of graphene, and its production process flow is as follows figure 1 As shown, specifically, the following steps are included:

[0048] A) Add 1kg of graphite powder into the double-layer reaction kettle, then add 40L of concentrated sulfuric acid, set the circulating water to 0°C, then slowly add 4kg of potassium permanganate, and perform the low-temperature intercalation reaction for 1 hour; set the circulating water temperature to 40°C, medium temperature Oxidation reaction for 1 hour; set the circulating water temperature to 70°C, and high temperature reaction for 1 hour;

[0049] B) After the reaction is completed, the material is transported to the plate and frame filter press for solid-liquid separation, the waste sulfuric acid is recovered and purified, and continues to be used in the next oxidation production. The first-grade graphene oxide obtained by filtration is placed in a dispersion tank, and 100L of pure w...

Embodiment 2

[0054] The present embodiment is a kind of production method of graphene, comprises the following steps:

[0055] A) Put 2kg of graphite powder into the double-layer reaction kettle, then add 60L of concentrated sulfuric acid, set the circulating water to 0°C, then slowly add 5kg of potassium permanganate, and perform low-temperature intercalation reaction for 1 hour; set the circulating water temperature to 40°C, medium temperature Oxidation reaction for 1 hour; set the circulating water temperature to 70°C, and high temperature reaction for 1 hour;

[0056] B) After the reaction is completed, the material is transported to a flat centrifuge for solid-liquid separation, the waste sulfuric acid is recovered and purified, and continued to be used in the next oxidation production. The first-grade graphene oxide obtained by filtration is placed in a dispersion tank, and 50L of pure water is added, and stirred Until the dispersion is uniform, add hydrogen peroxide to remove impuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com