Patents

Literature

91results about How to "To meet the needs of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

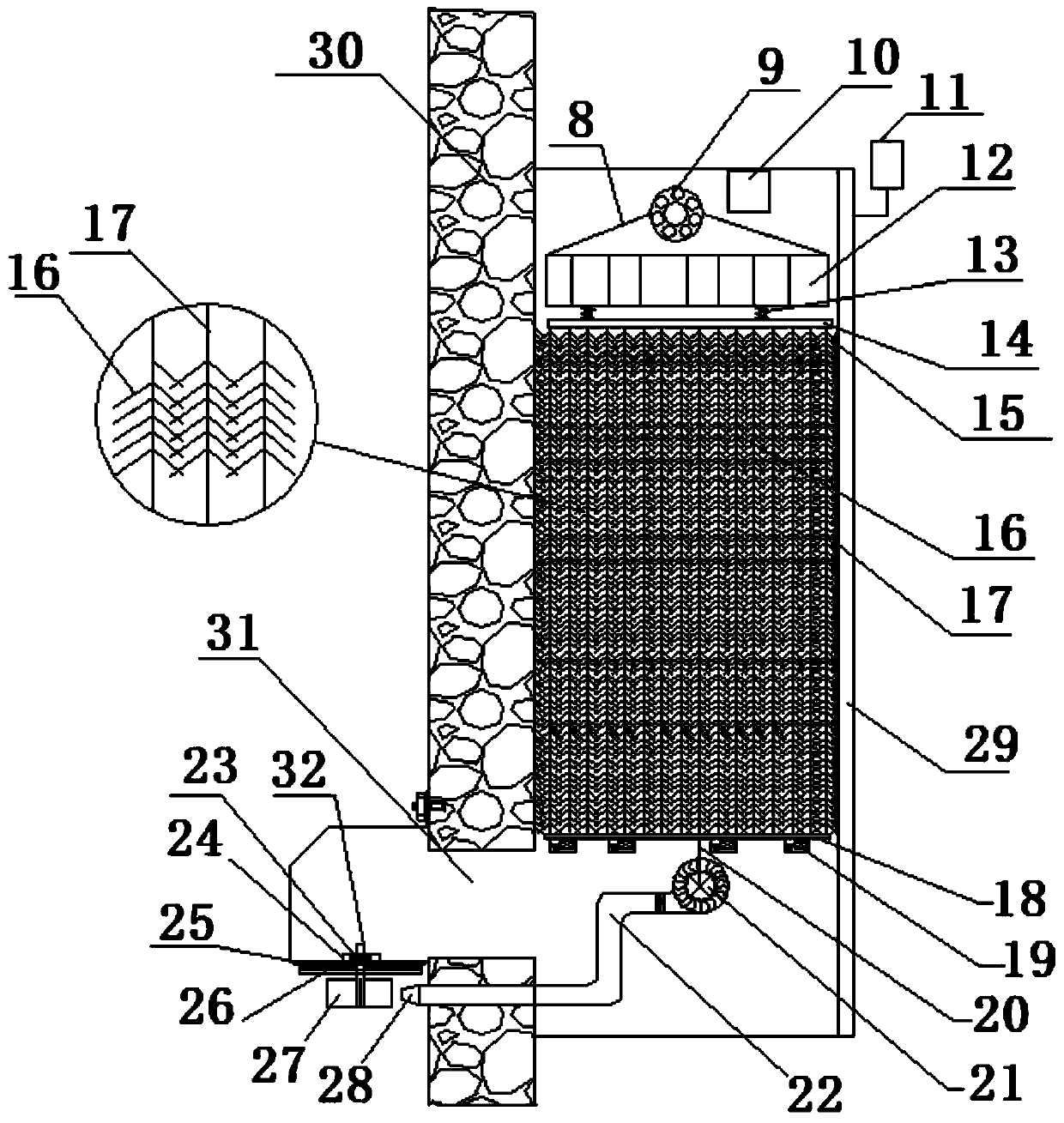

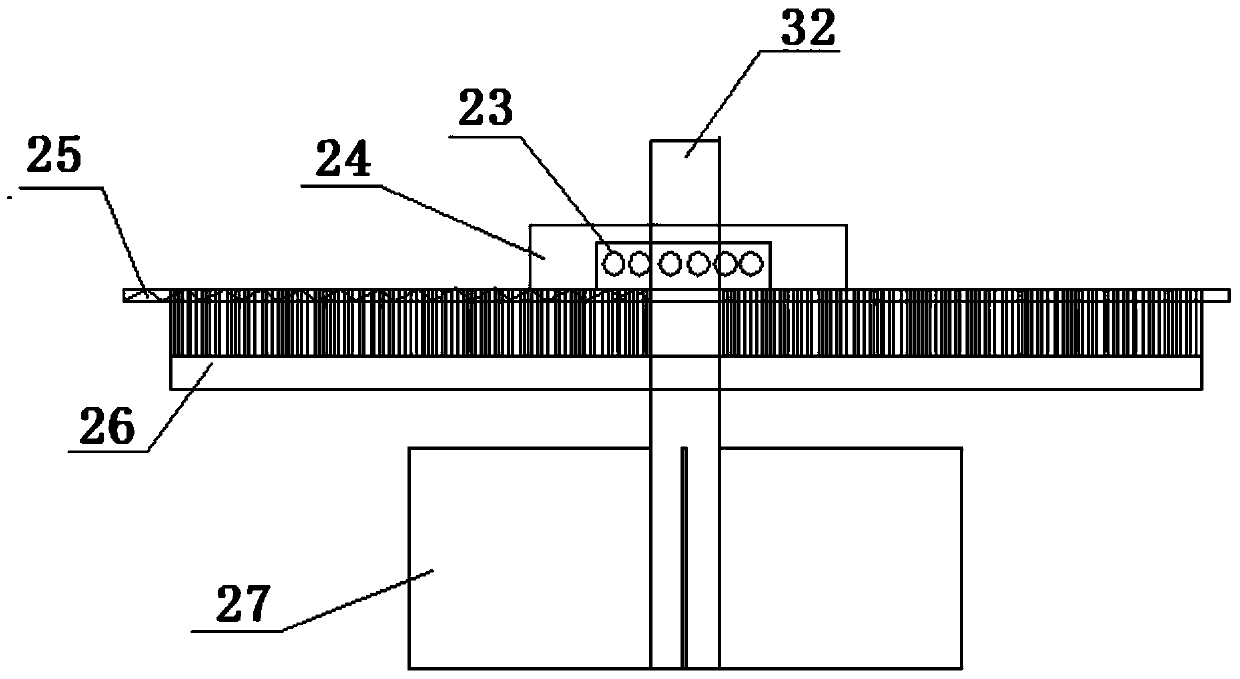

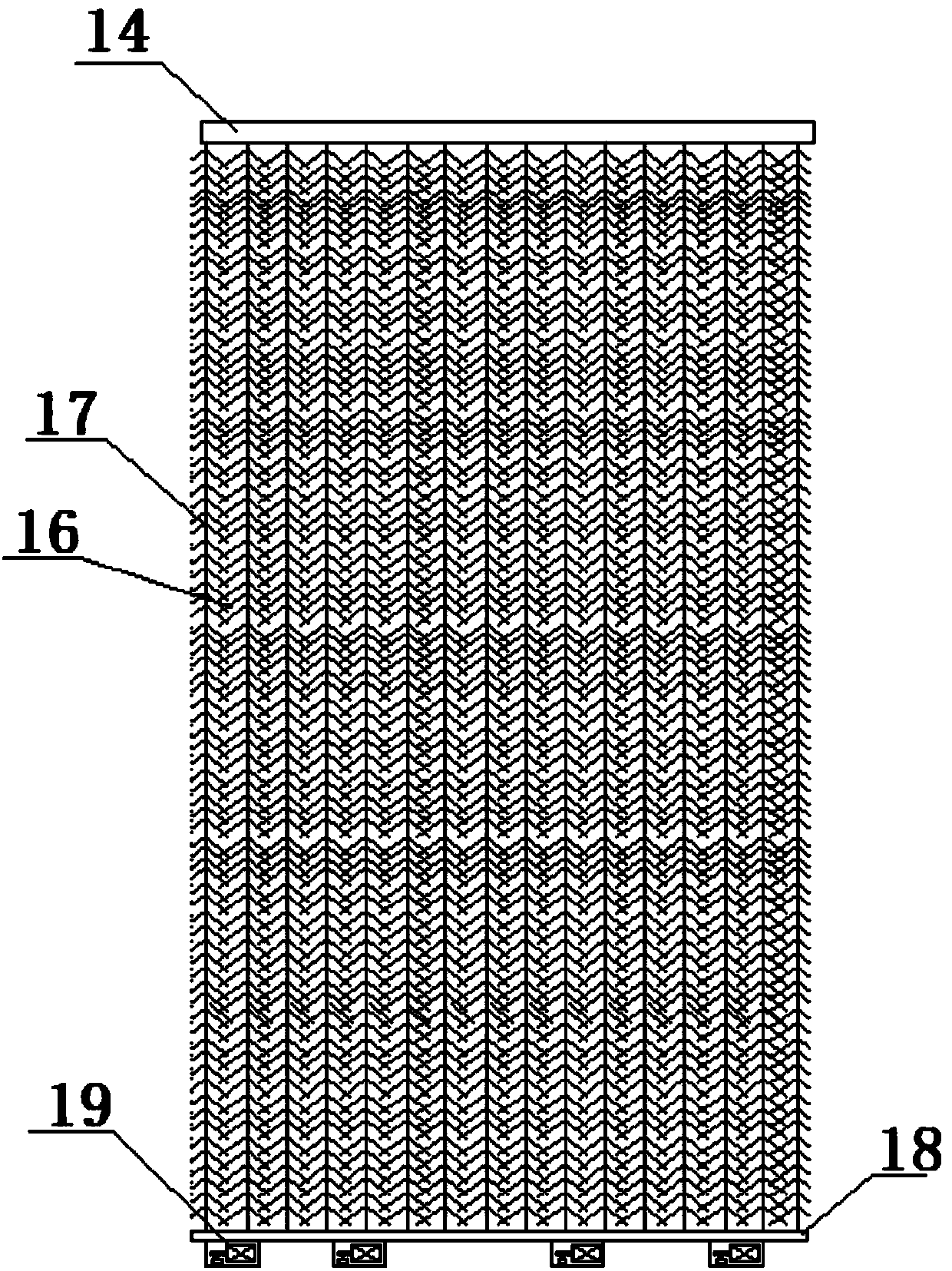

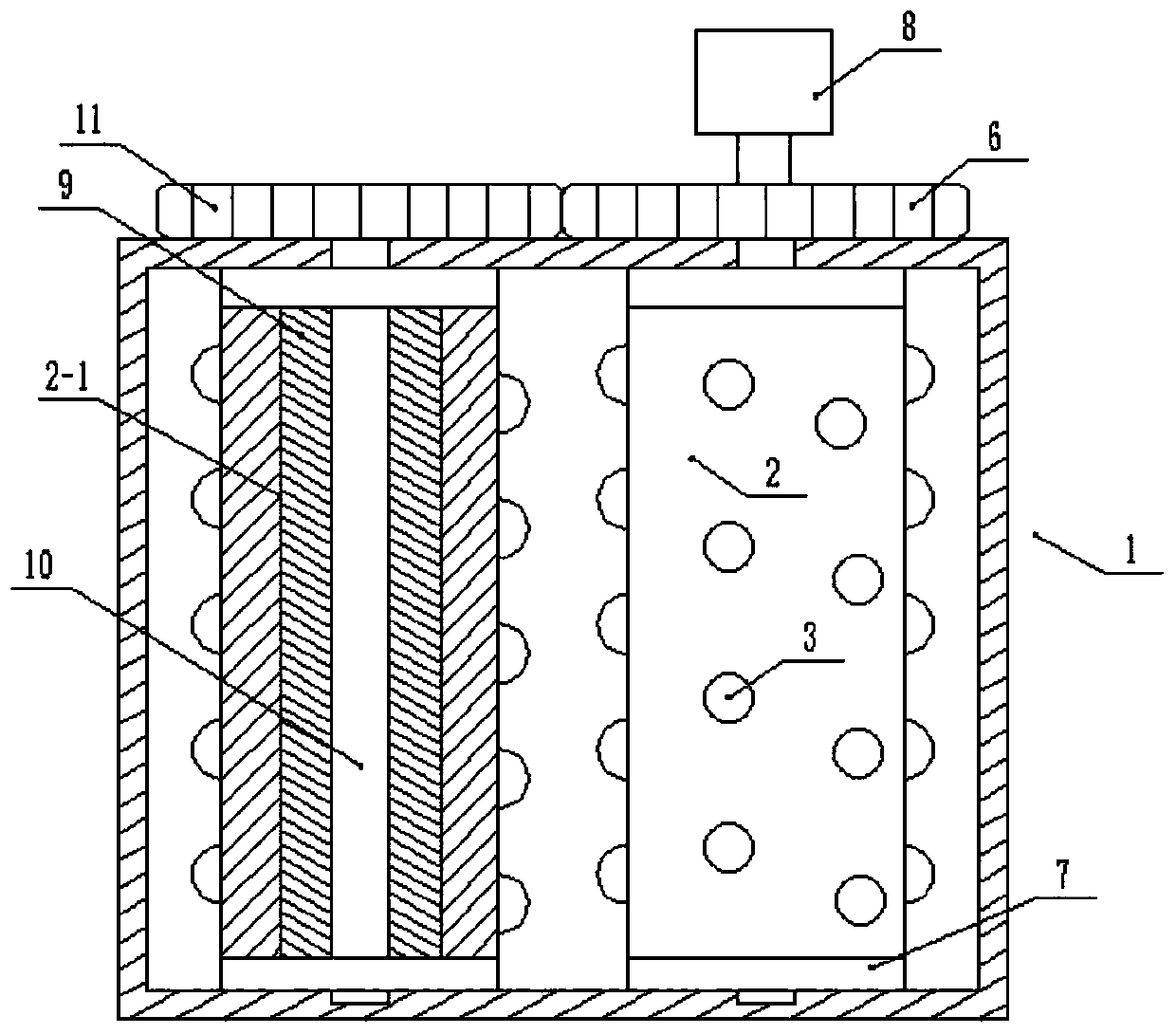

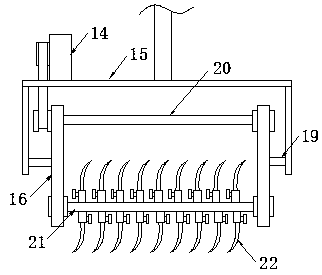

Air filter for intelligent ventilating system and air filtering method of air filter for intelligent ventilating system

ActiveCN103743053AExtended maintenance cycleLow maintenanceCombination devicesLighting and heating apparatusAir filtrationAir filter

The invention discloses an air filter for an intelligent ventilating system and an air filtering method of the air filter for the intelligent ventilating system. The intelligent ventilating system comprises a controller, the air filter comprises a filter tank, the air inlet side of the filter tank is communicated with an air inlet of the intelligent ventilating system, and an air outlet of the filter tank is communicated with the interior of the intelligent ventilating system; a cilium filtering net is arranged in the filter tank, one end of the cilium filtering net is connected with the filter tank, and the other end of the cilium filtering net is provided with a mini-type vibration motor connected with the controller; a pressure sensor connected with the controller is arranged at the air outlet of the filter tank. According to the air filter for the intelligent ventilating system and the air filtering method of the air filter for the intelligent ventilating system, automatic dedusting work of the air filter can be achieved; the maintenance period of the air filter is further prolonged, and the maintenance cost is effectively reduced.

Owner:芜湖中壹达节能科技有限公司

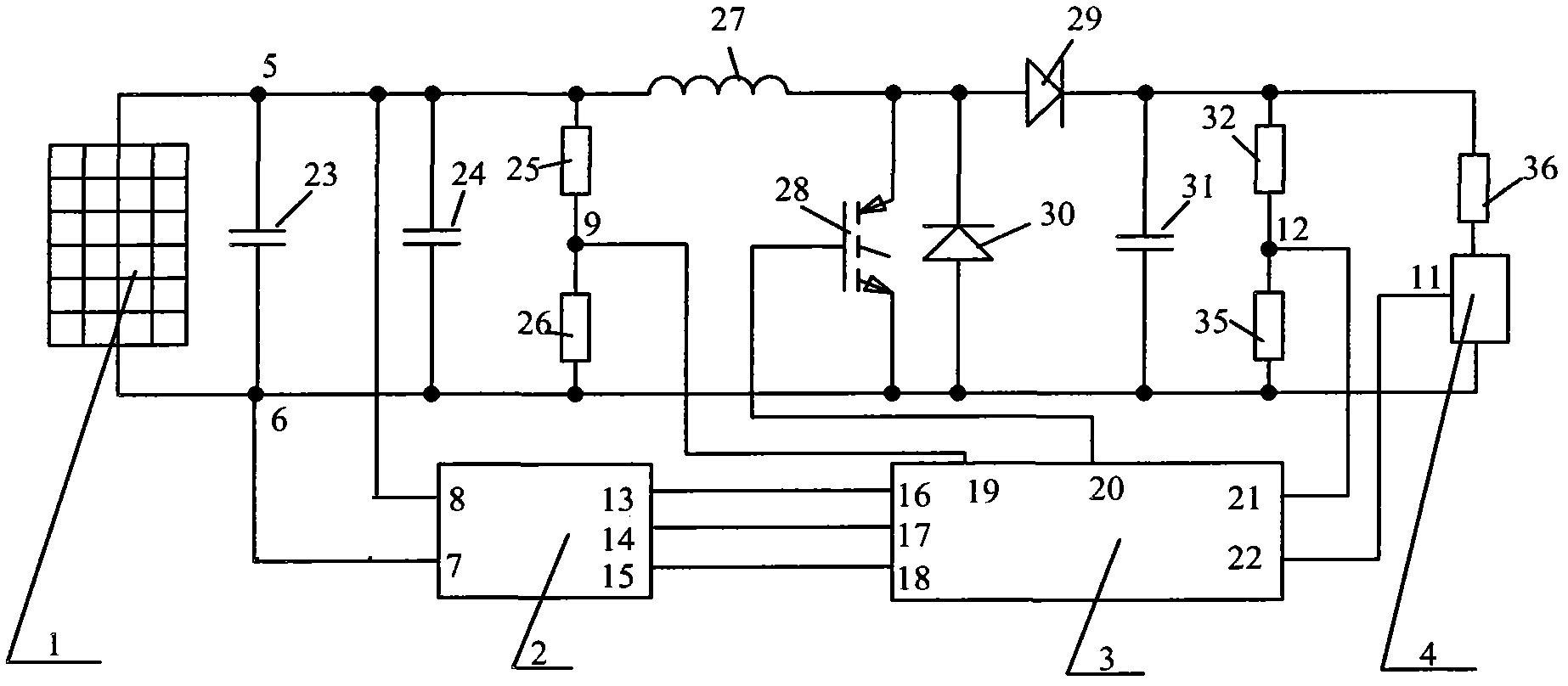

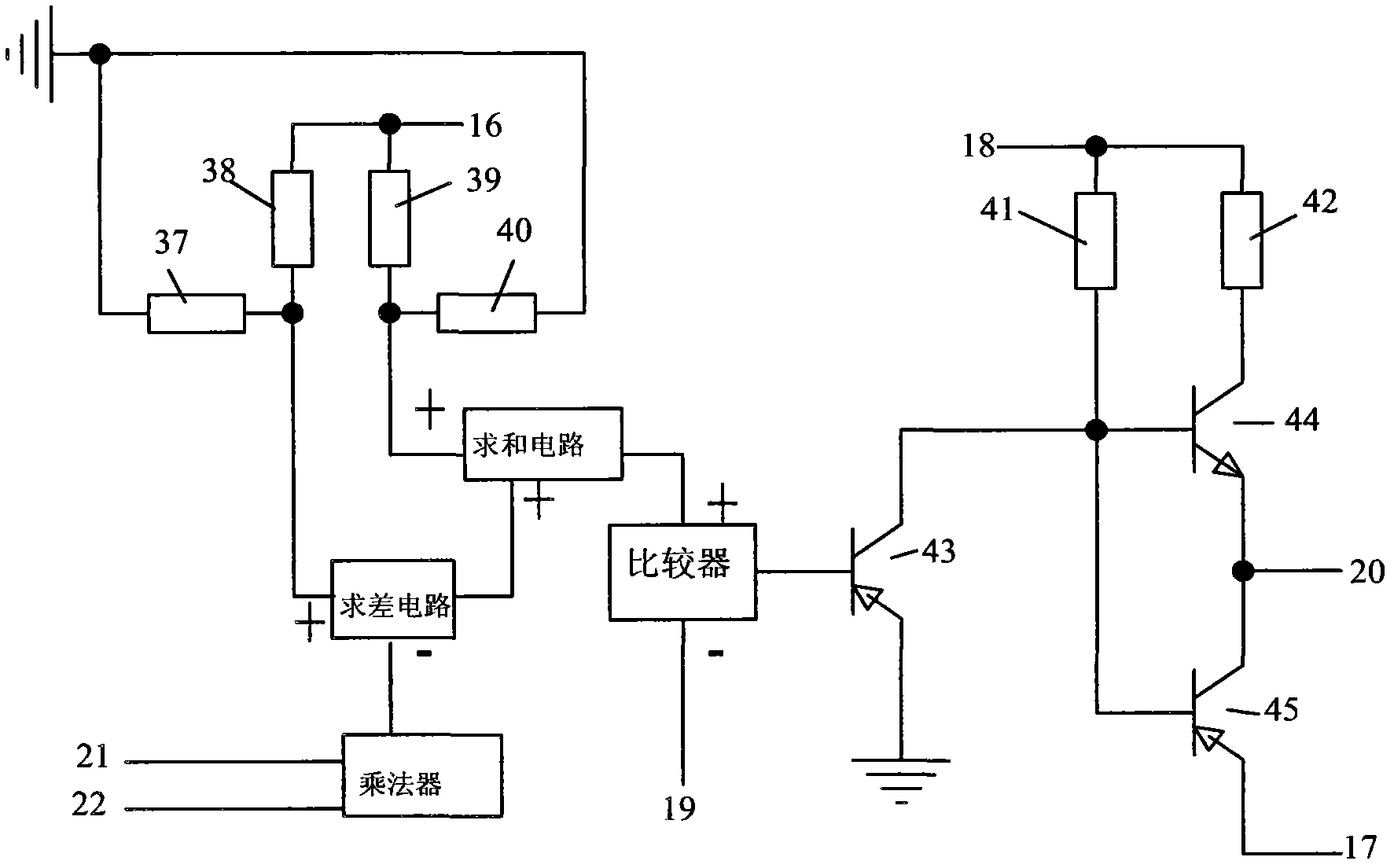

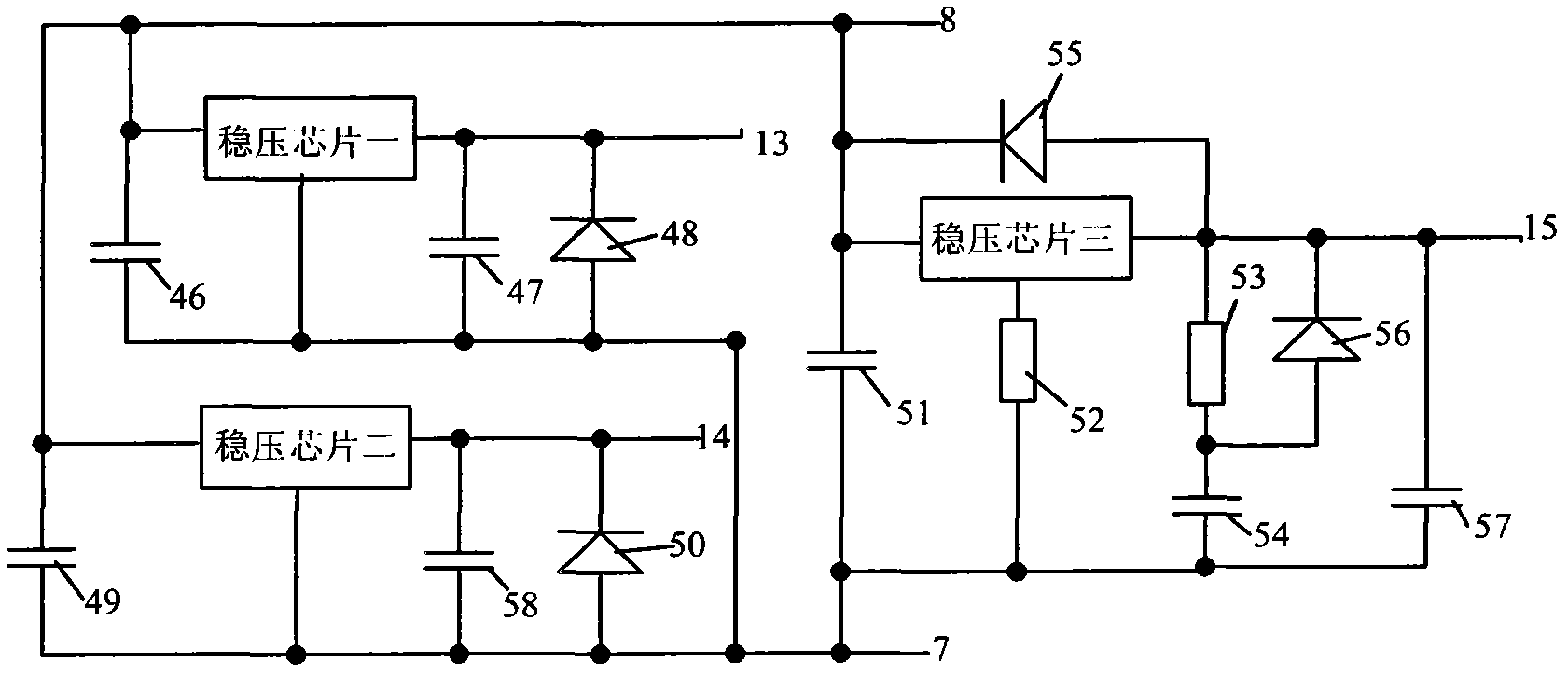

Automatic voltage regulating circuit and method for solar photovoltaic power generation system

InactiveCN102081419AAchieve constant power outputThe problem of saving energyPhotovoltaicsPhotovoltaic energy generationMicrocontrollerCapacitance

The invention provides an automatic voltage regulating circuit for a solar photovoltaic power generation system. The circuit comprises an auxiliary power circuit, an input voltage regulating capacitor, a voltage boosting inductor, an insulated gate transistor, a freewheel diode, a first diode, a second diode, a control drive circuit, an output voltage regulating capacitor, a load and a sampling circuit, wherein the voltage boosting inductor is connected with the input voltage regulating capacitor and the insulated gate transistor; the insulated gate transistor is connected with the control drive circuit and the input voltage regulating capacitor; the freewheel diode is connected with the insulated gate transistor; the first diode and the second diode are connected with the insulated gate transistor and the load; the output voltage regulating capacitor is connected with the first diode, the second diode and the freewheel diode; the load is connected with the output voltage regulating capacitor and an acquisition circuit respectively; and the acquisition circuit is connected with the input voltage regulating capacitor, the load, the output voltage regulating capacitor and the control drive circuit. The invention also provides an automatic voltage regulating method for implementing the method. Constant power output and power supply to the load can be realized without support of asinglechip.

Owner:SOUTH CHINA UNIV OF TECH

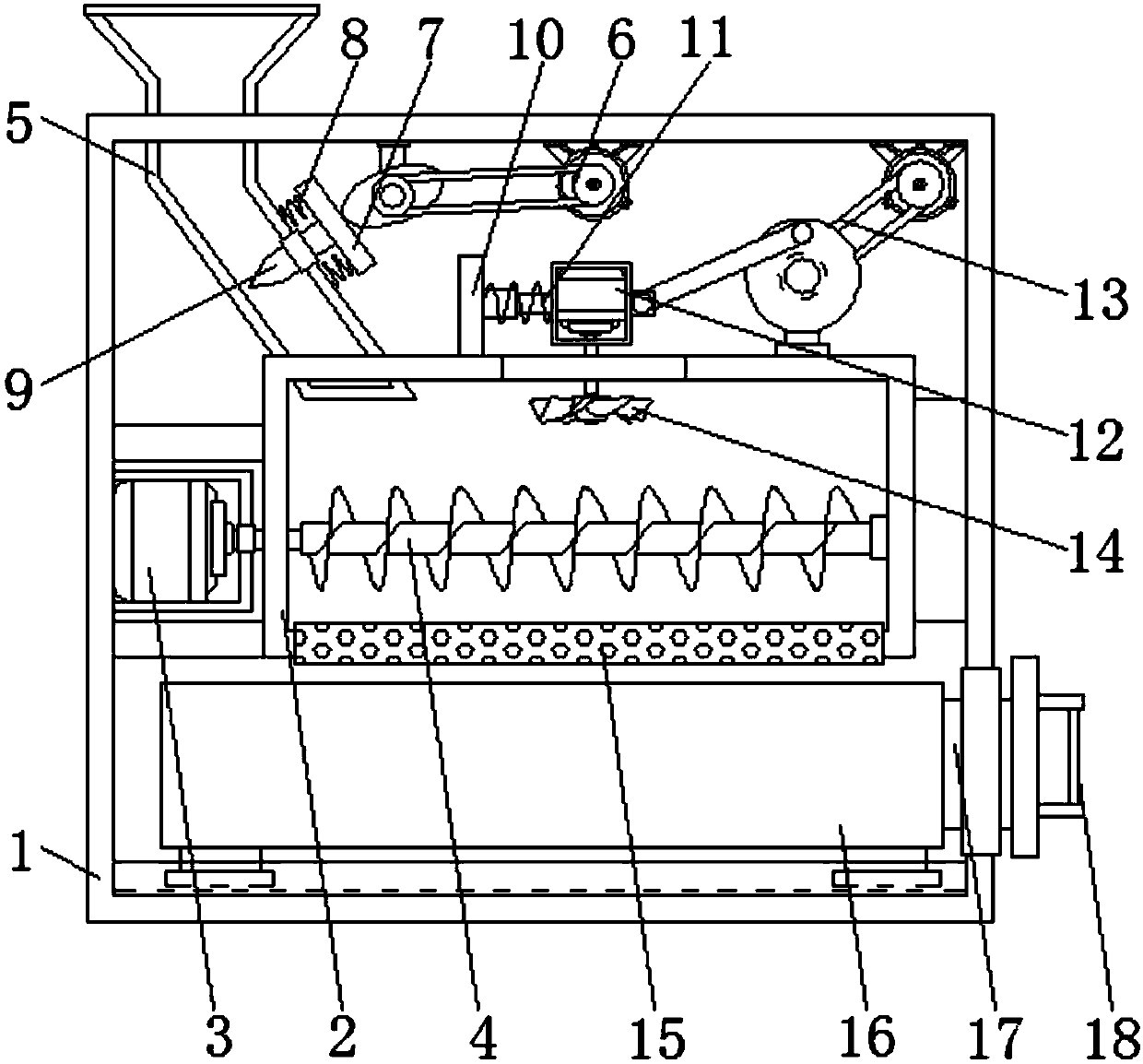

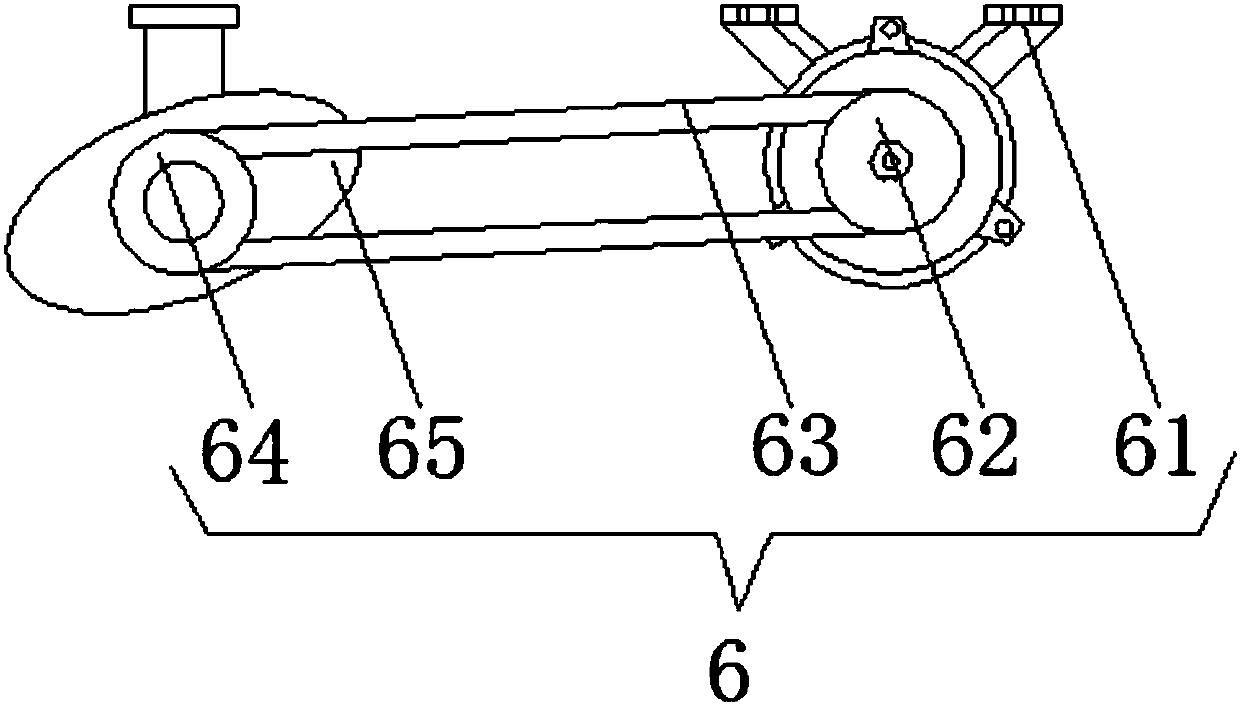

Feed crusher for corn straws

InactiveCN108015823AReduce the burden onThe straw is completely crushedFeeding-stuffGrain treatmentsCorn stoverPulverizer

The invention discloses a feed crusher for corn straws. The feed crusher comprises an outer frame, wherein an inner frame is fixedly connected to the right side of the inner wall of the outer frame, and a first motor is fixedly connected to the left side of the inner wall of the outer frame; one end of an output shaft of the first motor penetrates through the interior of the inner frame and extends into the interior of the inner frame; and a crushing rod is fixedly connected to the end, located in the inner frame, of the output shaft of the first motor, and the right end of the crushing rod isrotationally connected with the right side of the inner wall of the inner frame. The invention relates to the technical field of pulverizers. According to the feed crusher for the corn straws, the purpose of conveniently cutting the long straws is achieved, manual cutting is not needed, the burden of workers is greatly relieved, the use of people is facilitated, straw crushing is more complete, the influence on the later-period production of feed is prevented, transverse crushing is combined to use, so that the crushing efficiency is greatly improved, waste of time is reduced, and the crushedcorn straws can met the use requirements through a leakage net.

Owner:杨已颢

High-performance aluminum alloy for casting thin-walled structural parts and preparation method of high-performance aluminum alloy

ActiveCN111254325AGood casting performanceImprove filling abilityUltimate tensile strengthMaterials science

The invention discloses a high-performance aluminum alloy for casting thin-walled structural parts and a preparation method of the high-performance aluminum alloy. The aluminum alloy is prepared fromthe following components in percentage by weight: 9.5-11.0% of Si, less than or equal to 0.15% of Fe, 0.26-0.35% of Mg, less than or equal to 0.05% of Zn, 0.5-0.6% of Mn, less than or equal to 0.03% of Cu, 0.05-0.15% of Ti, less than or equal to 0.002% of Ca, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.005% of Sb, 0.010-0.025% of Sr, less than orequal to 0.01% of Cd, less than or equal to 0.001% of Li and the balance of Al. According to the high-performance aluminum alloy for casting the thin-walled structural parts and the preparation methodof the high-performance aluminum alloy, design and study are carried out in terms of composition design, material selection, purification treatment, casting process and the other aspects, and the aluminum alloy with greater than or equal to 220 MPa of tensile strength, greater than or equal to 130 MPa of yield strength and greater than or equal to 6.0% of elongation is provided, and can meet theproduction demand of automobile shock absorber towers.

Owner:保定隆达铝业有限公司 +2

Additive for aluminum alloy fusant and addition method thereof

The invention relates to an additive for removing magnesium of aluminum alloy fusant and an addition method thereof. The addition method comprises the following steps of: appropriately screening natural silica sand serving as a raw material to obtain a silica sand additive, melting aluminum alloy by heating under atmospheric environment to obtain aluminum fusant, and keeping the temperature of the aluminum fusant at 750 DEG C; and adding the silica sand additive which is 7 percent of the total mass of the aluminum fusant into the aluminum fusant and stirring for 6 minutes to remove generated scruffs, wherein the step of adding the silica sand additive can be repeated from multiple times so as to reduce the magnesium content of the aluminum alloy fusant further. In the method, the silica sand additive is low in cost, abundant in reserves, safe, innocent and pollution-free, can effectively remove Mg of the aluminum alloy fusant to recover waste and wasted aluminum alloy, and greatly saves social resources and energy sources, thereby having wide application prospect and application value.

Owner:NINGBO XIANGBO MACHINE

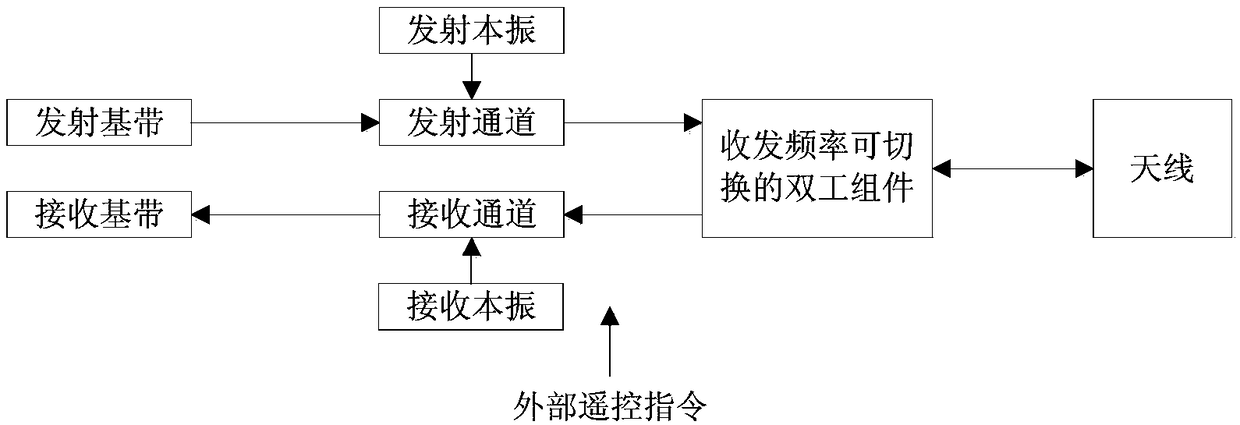

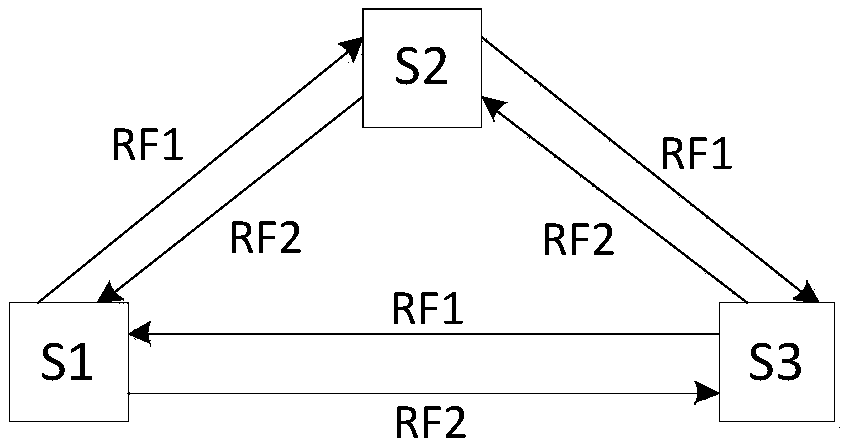

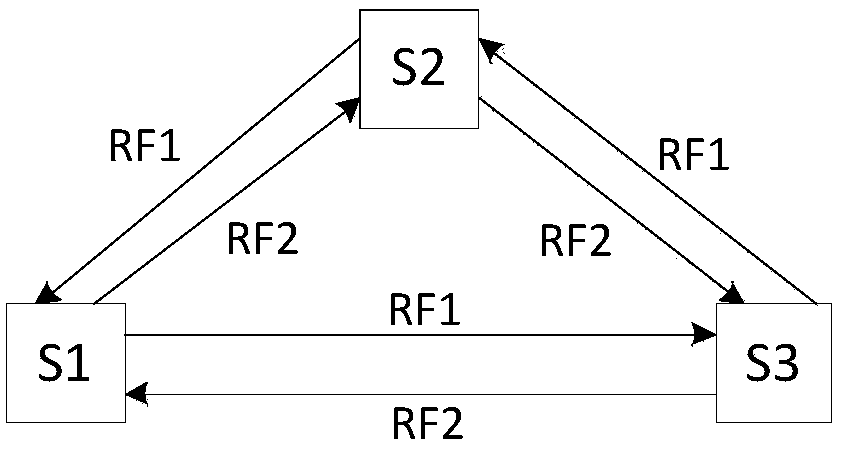

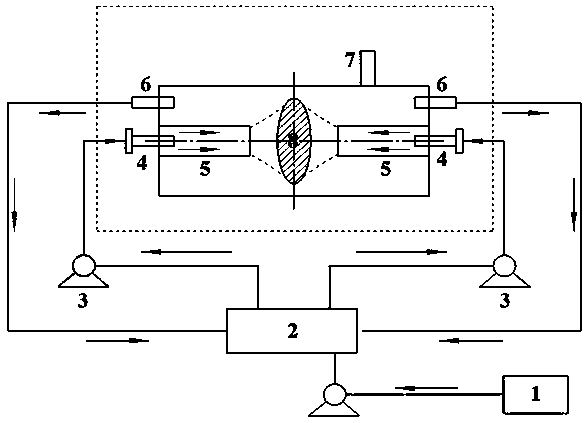

Full-duplex inter-satellite link system capable of switching receiving and sending frequencies, and method

ActiveCN108736955ARealize the transmit frequencyResolution frequencyRadio transmissionHigh level techniquesLocal oscillatorOrbit

The invention relates to a full-duplex inter-satellite link system capable of switching receiving and sending frequencies, and a method, and belongs to the technical field of inter-satellite link technology design. The system comprises more than two satellites; each satellite is provided with multiple full-duplex inter-satellite link devices; and each full-duplex inter-satellite link device on each satellite comprises a transmitting baseband, a receiving baseband, a transmitting local oscillator, a transmitting channel, a receiving local oscillator, a receiving channel, a duplex component capable of switching the receiving and sending frequencies, and an antenna. The full-duplex inter-satellite link system capable of switching the receiving and sending frequencies is realized; design manufacturing of the inter-satellite link devices is simplified; therefore, batch production of the inter-satellite link devices can be carried out; and re-configuration of on-orbit inter-satellite links also can be flexibly carried out.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

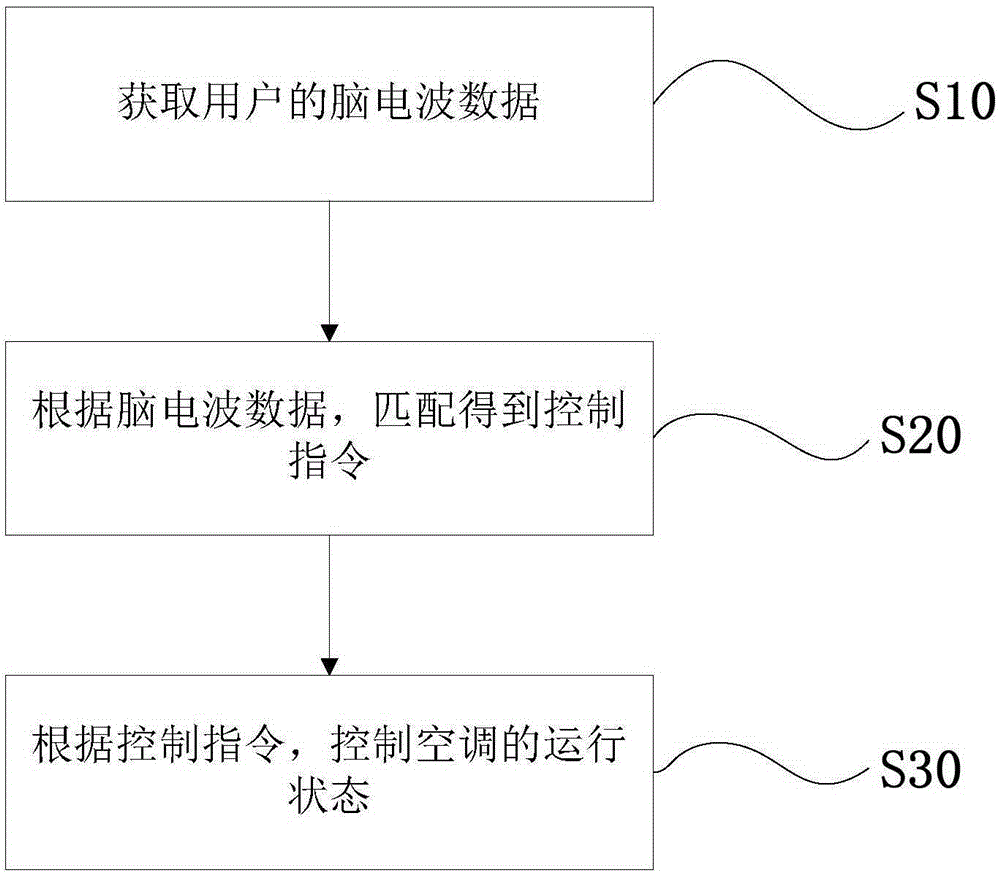

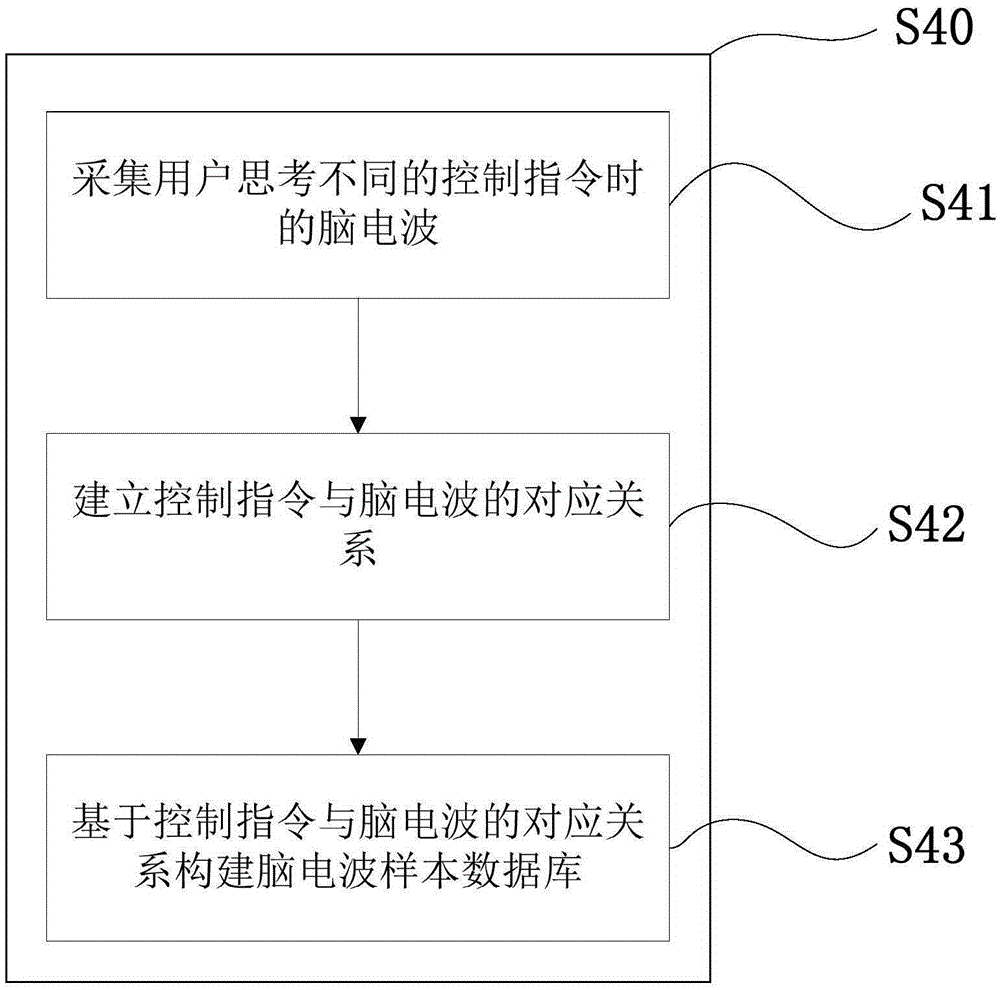

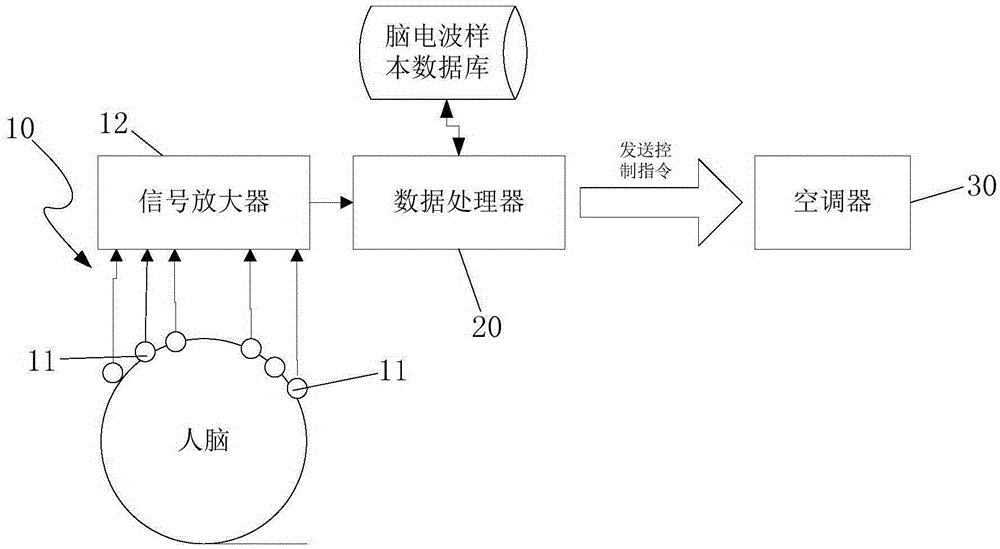

Air conditioner control method and air conditioner control system

InactiveCN105258284ATo meet the needs of useEffective controlMechanical apparatusSpace heating and ventilation safety systemsControl systemBrain waves

The invention provides an air conditioner control method and an air conditioner control system. The air conditioner control method comprises the following steps of obtaining brain wave data of a user; according to the brain wave data, carrying matching to obtain a control instruction; and according to the control instruction, controlling the running state of an air conditioner. According to the air conditioner control method and the air conditioner control system, the problem that in the prior art, some users with action barriers cannot control the air conditioner is solved.

Owner:GREE ELECTRIC APPLIANCES INC

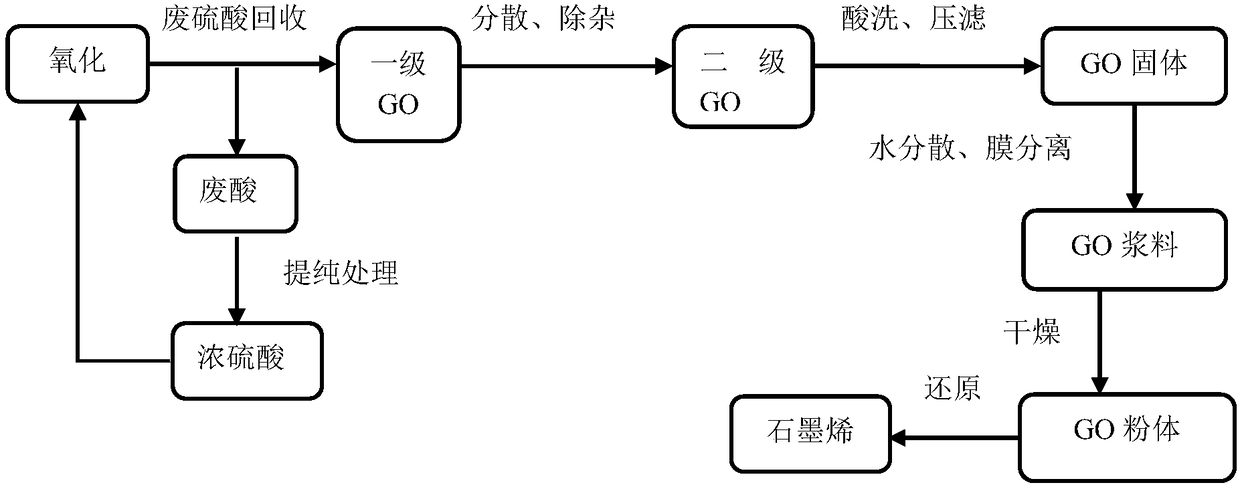

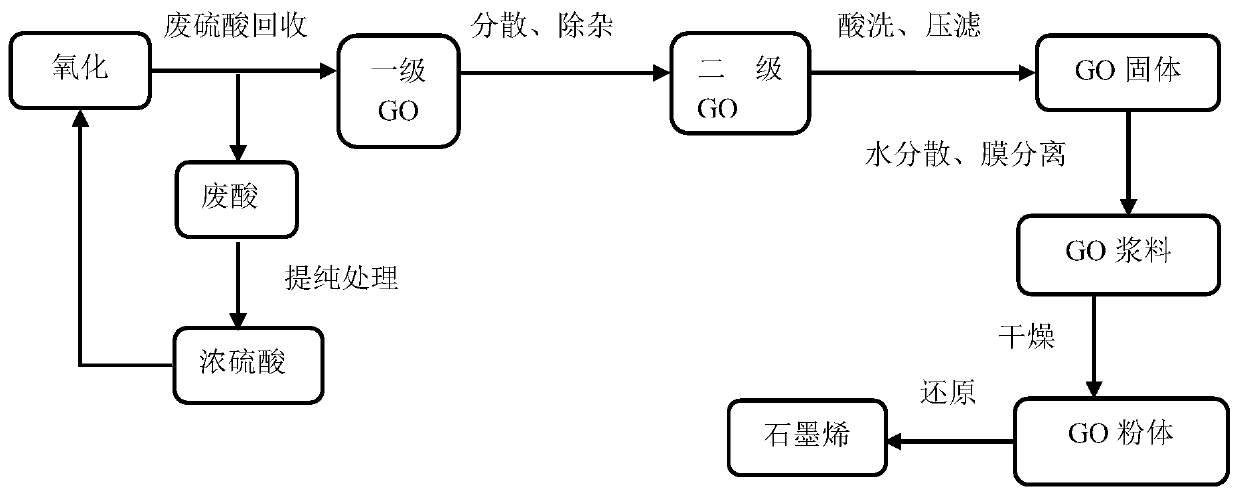

Graphene, production method and use thereof and battery

ActiveCN108545724AReduce manganese contentReduce processingCell electrodesGrapheneSewageLithium-ion battery

The invention provides graphene, a production method and use thereof and a battery, relating to the technical field of graphene. The production method comprises the following steps: (A) after graphitegenerates oxidation reaction with concentrated sulfuric acid and potassium permanganate, carrying out solid-liquid separation, so as to recycle concentrated sulfuric acid and obtain first-grade graphene oxide solids; and (B) removing impurities from first-grade graphene oxide solids by virtue of hydrogen peroxide, carrying out solid-liquid separation so as to obtain second-grade graphene oxide solids, sequentially washing with hydrochloric acid and water so as to obtain refined graphene oxide, and carrying out reduction on refined graphene oxide, so as to obtain graphene. The production method can be used for relieving the technical problems that graphene produced by virtue of an existing graphene production process is high in content and is not applicable to lithium ion battery materials, the amount of sewage produced during the purification is large, and environmental pollution is easily caused, and the purpose of reducing the content of graphene is achieved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

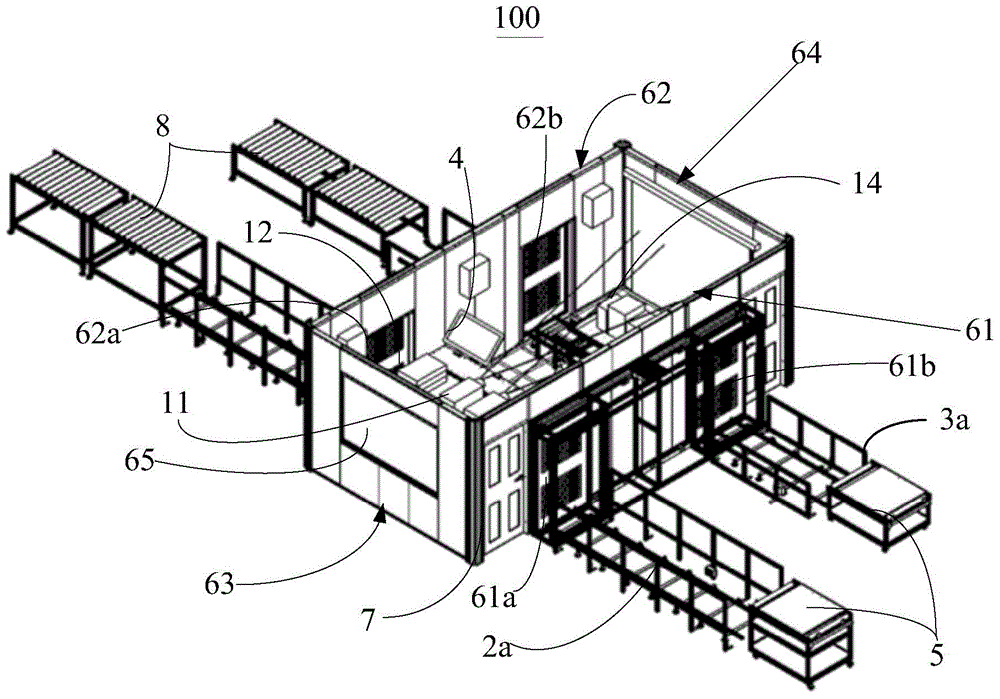

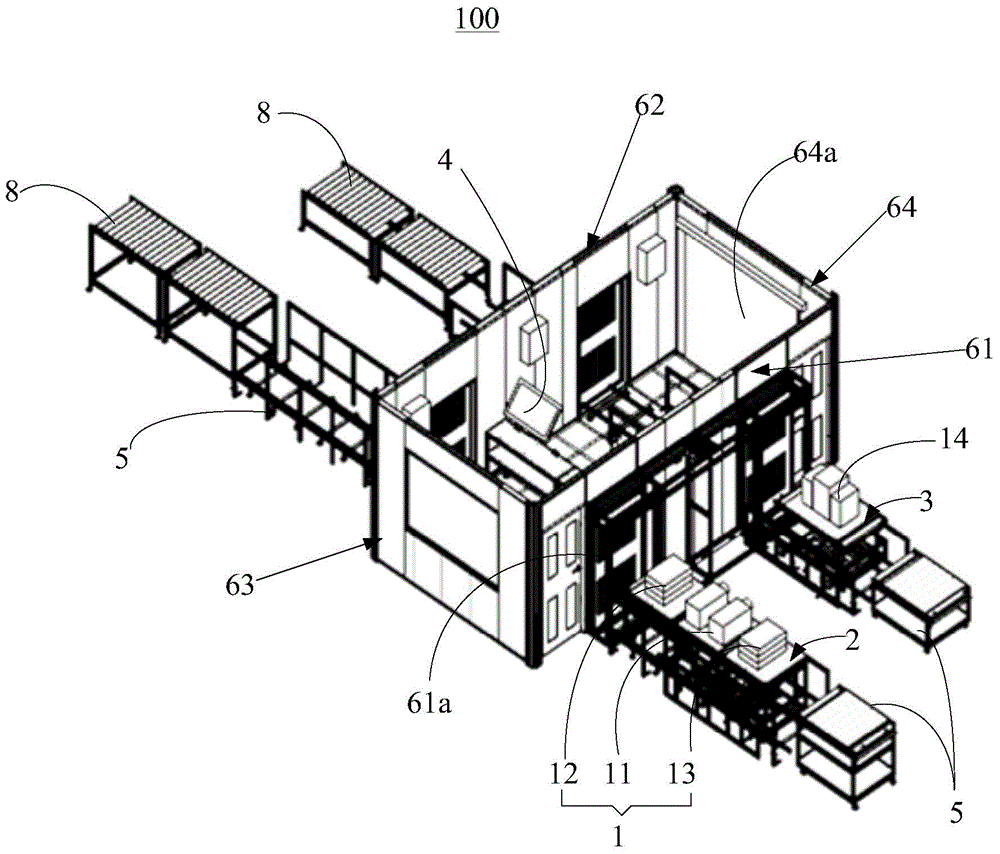

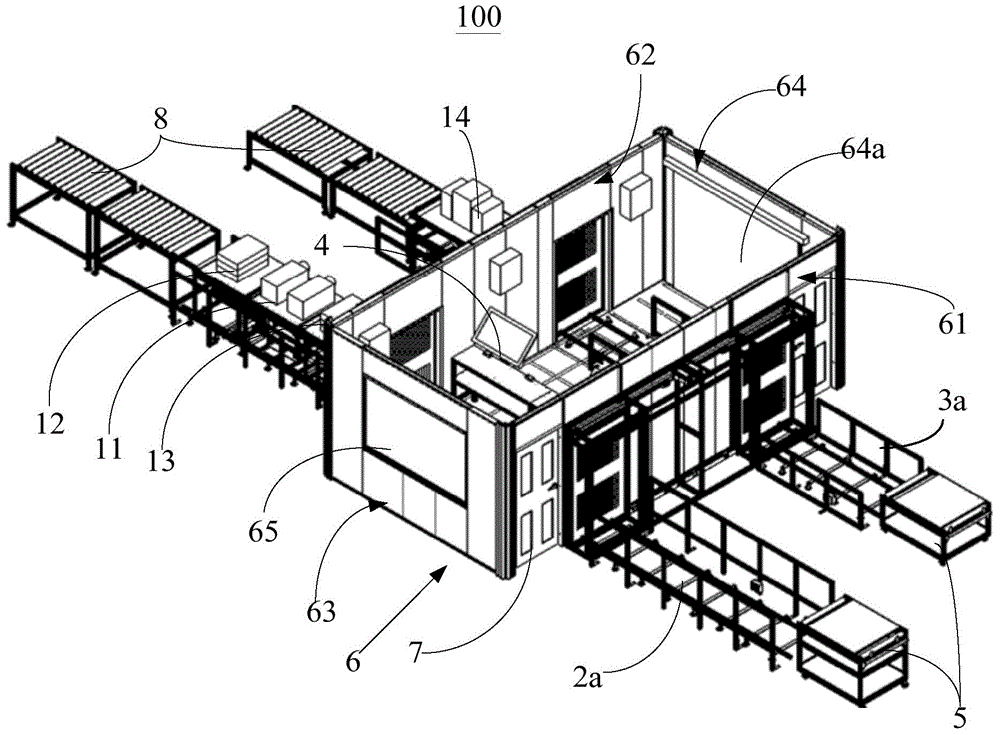

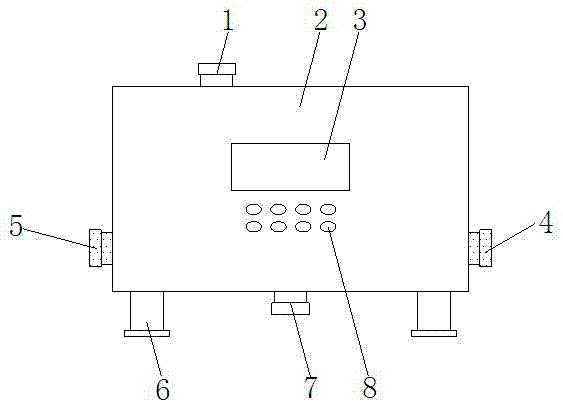

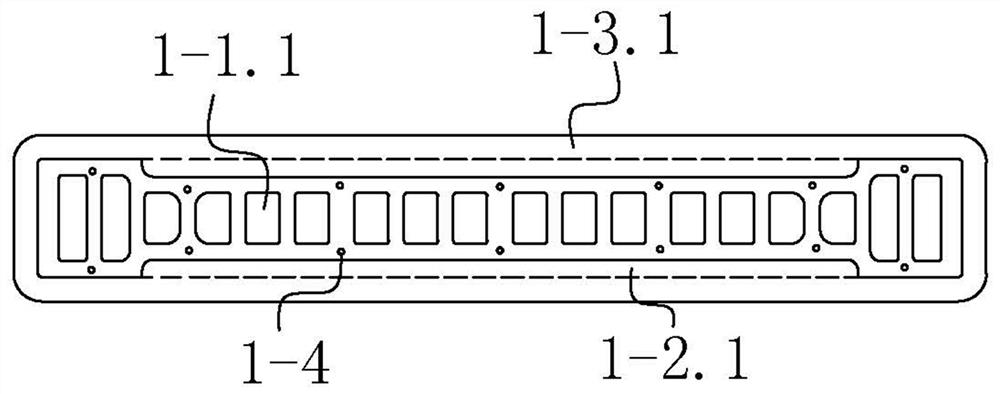

Detection system and detection method for home theater equipment

ActiveCN105181369ATo meet the needs of useMeet actual use needsStructural/machines measurementProjection screenEmbedded system

The invention discloses a detection system and detection method for home theater equipment. Home theater equipment comprises a projector, a middle control device and a play device. The detection system of the home theater equipment comprises a detection house, a detection device in the detection house and a conveying device for conveying the home theater equipment. The detection device comprises a cable, a projection screen for projection of the projector, a detector which is electrically connected with the on-line home theater equipment, and a display screen which is electrically connected with the detector. The home theater equipment, that is, the projector, the middle control device and the play device, can perform on-line detection through the detection device; through the detection results on the display screen, whether the on-line performance of the projector, the middle control device and the play device satisfies the using requirement; and the method and system can guarantee that home theater equipment delivered from a factory can satisfy the requirement for practical use when the home theater equipment is on-line.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

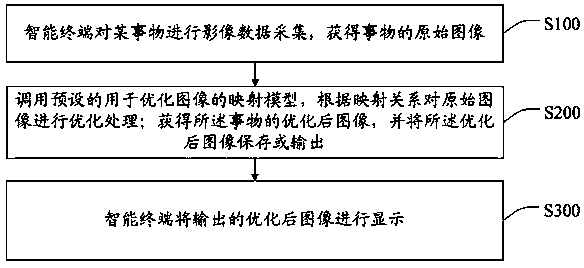

Image processing method, storage medium and intelligent terminal

ActiveCN107945139ATo meet the needs of useImprove image qualityImage enhancementImage analysisImaging processingImaging quality

The invention discloses an image processing method, a storage medium and an intelligent terminal. The method comprises the following steps of the intelligent terminal carrying out image data acquisition on an object and obtaining an original image of the object; calling a preset mapping model for optimizing the image and performing optimization processing on the original image according to the mapping relation; obtaining an optimized image of the object, and storing or outputting the optimized image; and the intelligent terminal displaying the output optimized image. The mapping model for optimizing an image is created. The original image of a certain object can be optimized by automatically calling the mapping model after the original image of the certain object is obtained by the intelligent terminal. The image quality and the imaging speed are improved, and the service life of equipment is prolonged. Particularly for low-end equipment with poor imaging quality, the use requirementsof the user can be met by only changing the algorithm of the imaging quality without changing hardware. The imaging quality is improved, and the imaging speed is increased to a certain extent.

Owner:SHENZHEN UNIV

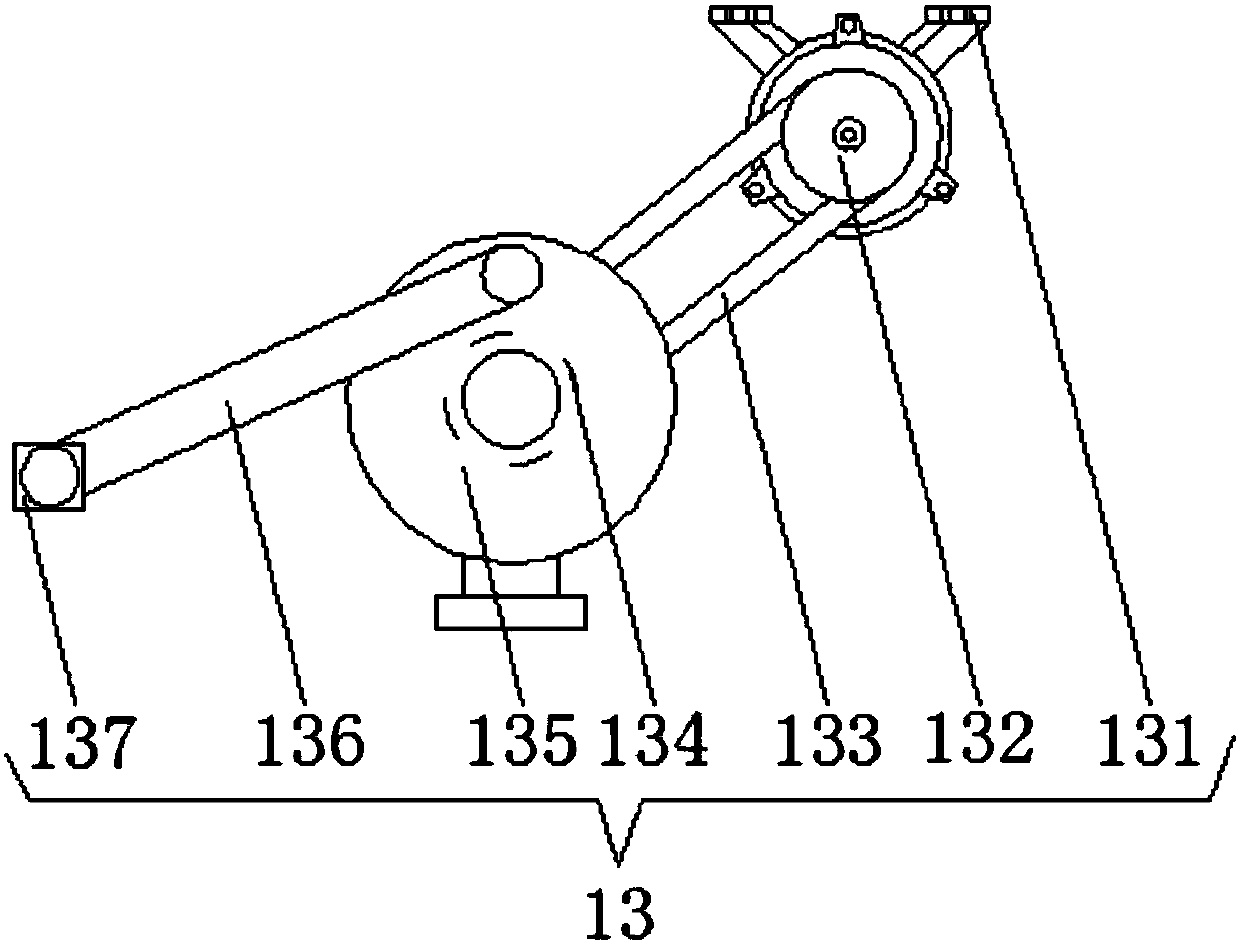

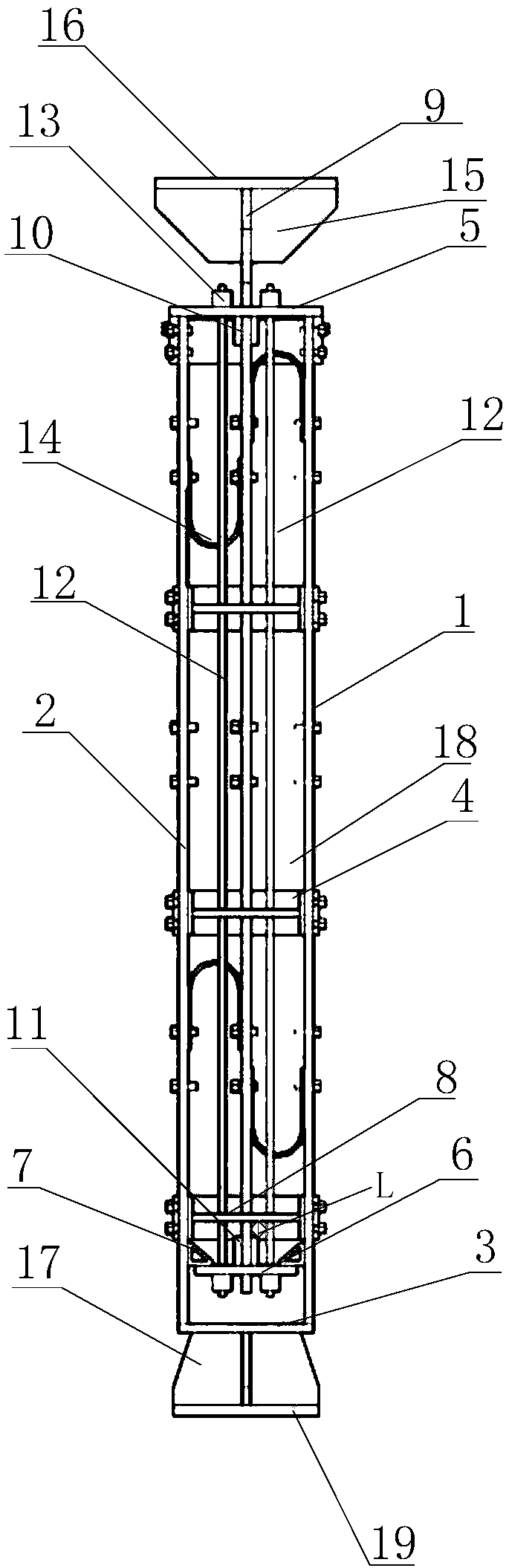

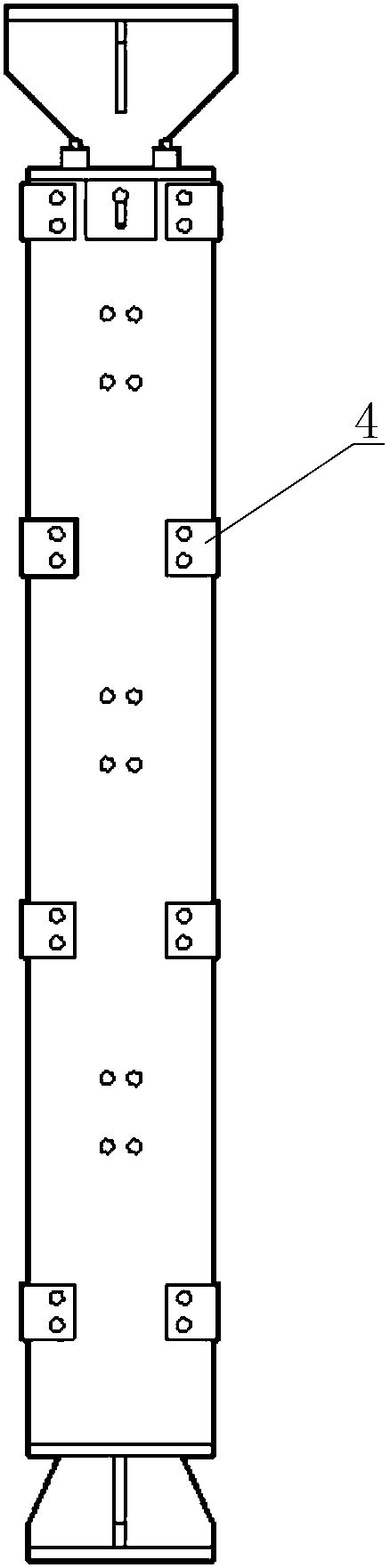

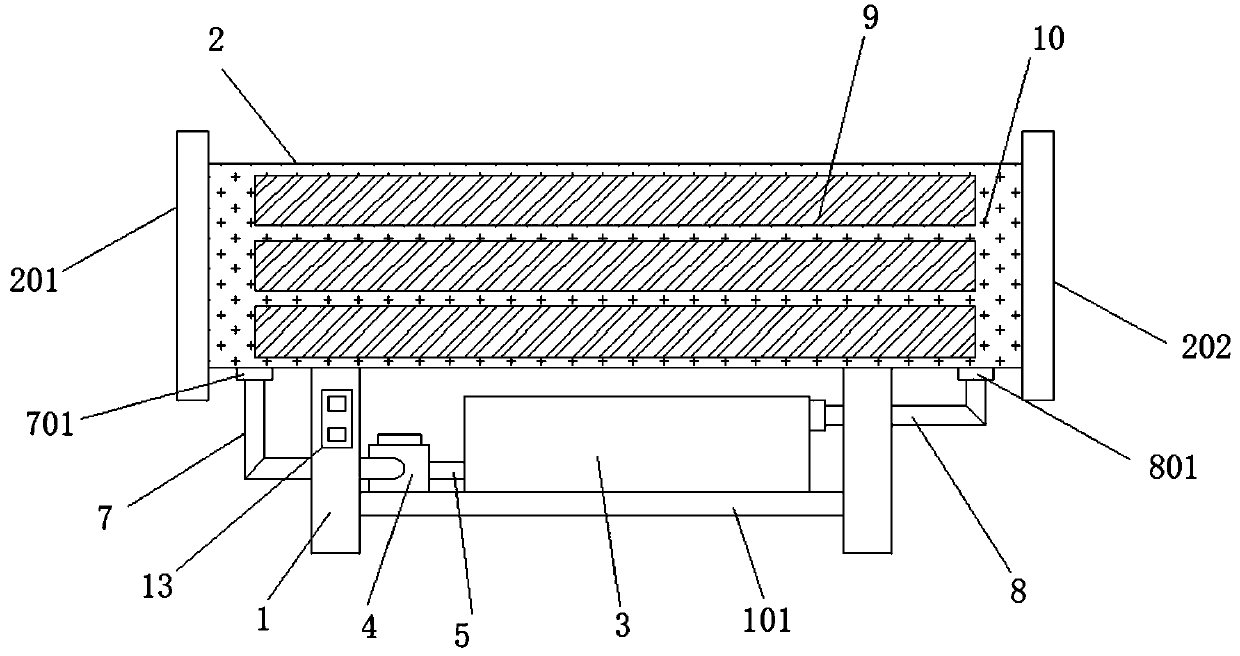

Assembly type energy dissipation support device capable of automatically resetting

PendingCN107893563AQuick releaseRealize industrializationProtective buildings/sheltersShock proofingSnubberInternal energy

The invention discloses an assembly type energy dissipation support device capable of automatically resetting, and belongs to the field of civil engineering. The assembly type energy dissipation support device capable of automatically resetting comprises a peripheral constraint unit, an automatic resetting unit, an inner core connecting unit, and an interior energy dissipation unit. The peripheralconstraint unit comprises a first constraint plate, a second constraint plate, a base plate, and a box iron constraint unit; the automatic resetting unit comprises a first limiting baffle, a third limiting baffle, a third small baffle, a second limiting baffle, and a prestressed reinforcement; and the prestressed reinforcement is fixed by an anchorage device, the inner core connecting unit comprises a core plate, a first small baffle, and a second small baffle. According to the assembly type energy dissipation support device capable of automatically resetting, existing dampers can be fully utilized, multiple dampers can be assembled to an automatic resetting energy dissipation support by an automatic resetting device.

Owner:SHANDONG UNIV

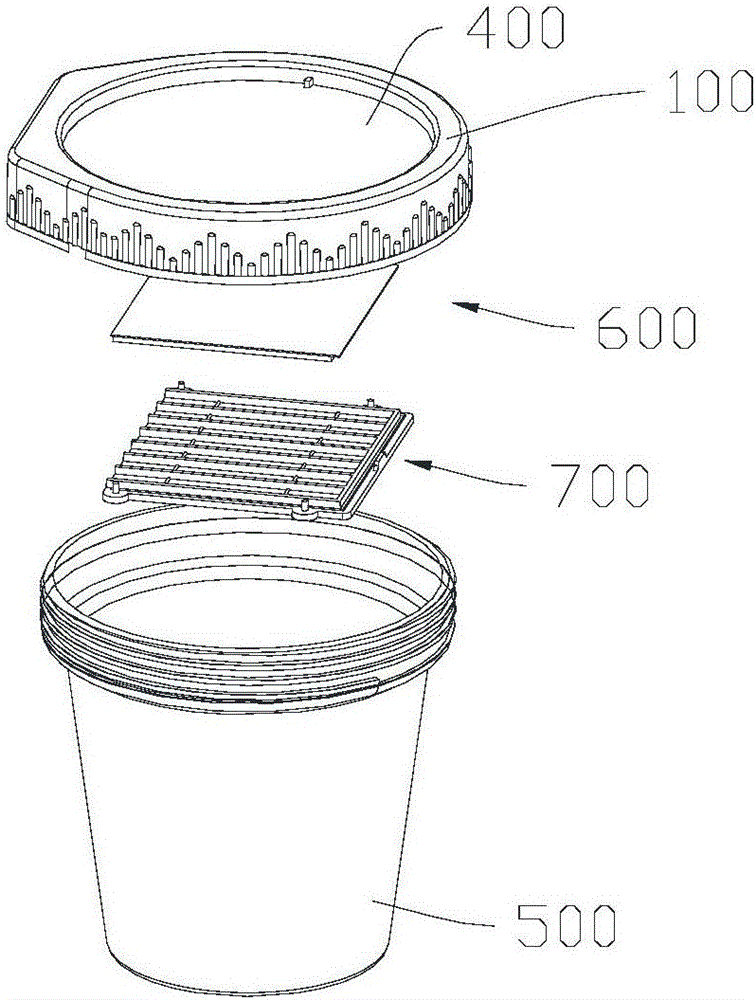

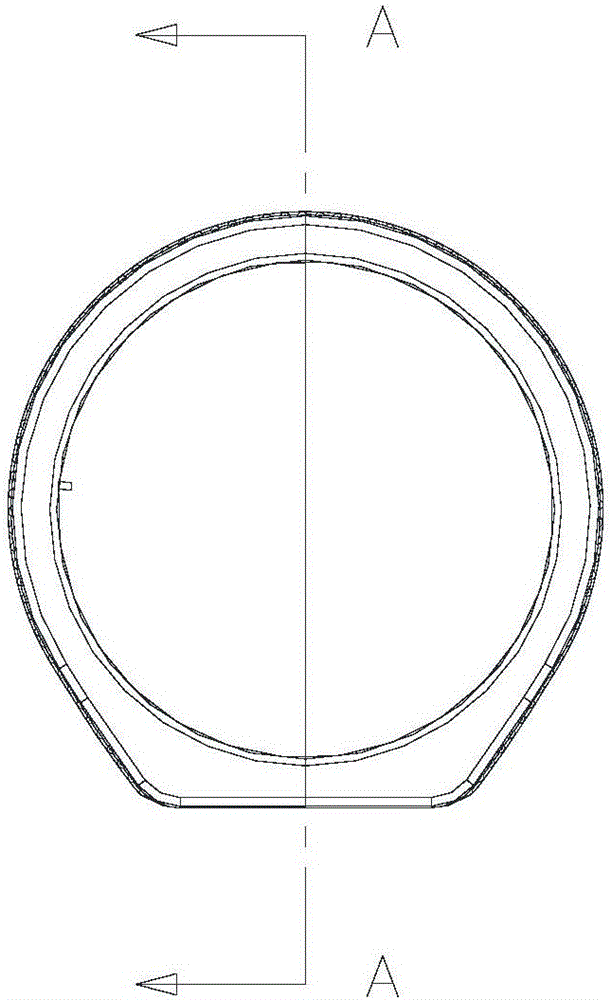

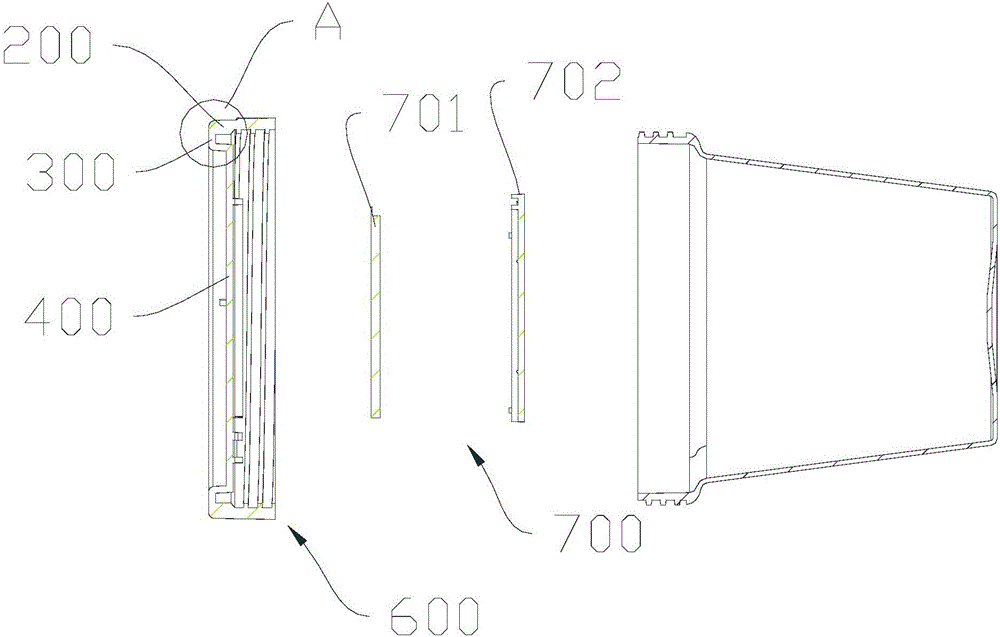

Urine cup

The invention relates to a urine detection device, and discloses a urine cup, comprising a protruding part arranged on the surface of the urine cup, the protruding part is formed by protruding from the surface of the urine cup and cooperates with the protruding edge The cover sheet is fixedly connected along the protruding edge and forms a cavity inside the protruding part. The invention has the advantages of greatly reducing the difficulty of the manufacturing process, and the obtained urine cup, especially the lid of the urine cup, has a firm structure and has a sealing effect, and can be sealed without additional sealing strips, and the liquid in the urine cup It is always limited to the inside of the urine cup, will not leak to the outside of the urine cup, is easy to clean, and has good application value.

Owner:杭州康永生物技术有限公司

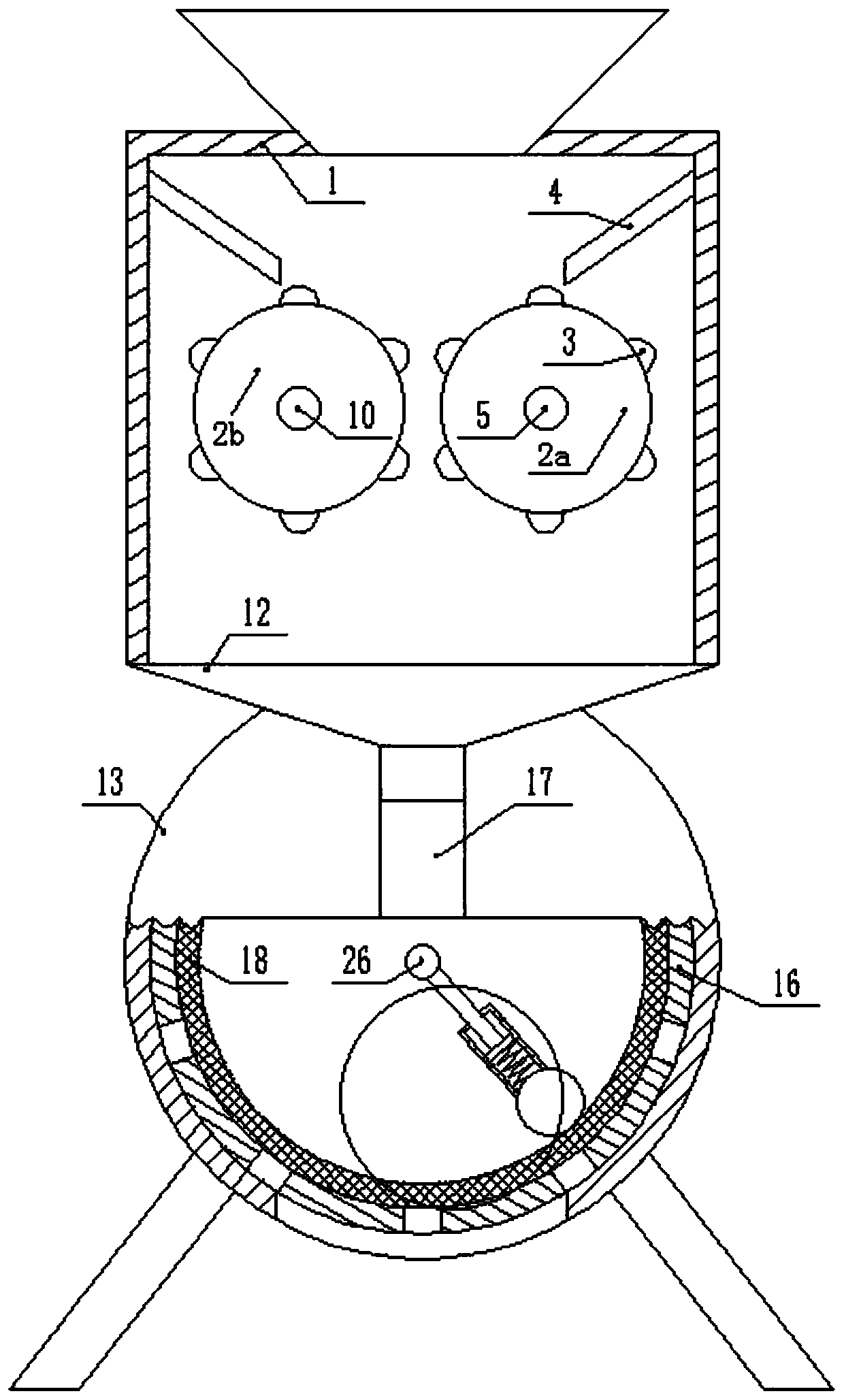

Soil crushing device

ActiveCN111068830AGuaranteed uptimeTo meet the needs of useSievingScreeningRotational axisRubber ring

The invention discloses a soil crushing device. The soil crushing device comprises a primary crushing device and a grinding device, wherein the bottom end of the primary crushing device and a secondary crushing device are connected through a funnel and an oblique pipe; and the primary crushing device comprises a crushing barrel, a first crushing assembly and a second crushing assembly. The first crushing assembly comprises a first crushing roller, a first motor, a first gear and a first rotary shaft; the second crushing assembly comprises a second crushing roller, a second gear, a second rotary shaft and a rubber ring, and a plurality of protrusions are arranged on the surfaces of the first crushing roller and the second crushing roller. The grinding device comprises a grinding assembly, asecond motor, a fourth gear, a third gear, a first barrel body, an apertured barrel, an eccentric gear and a balancing weight, wherein a filter net is fixed into the apertured barrel, and the grinding assembly comprises a grinding roller, a sliding rod, a slider, a second barrel body and a spring. By means of the soil crushing device, primarily crushed soil can be ground and crushed, the grindingroller is protected, the soil using requirements are met, and the service life of the device is prolonged.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

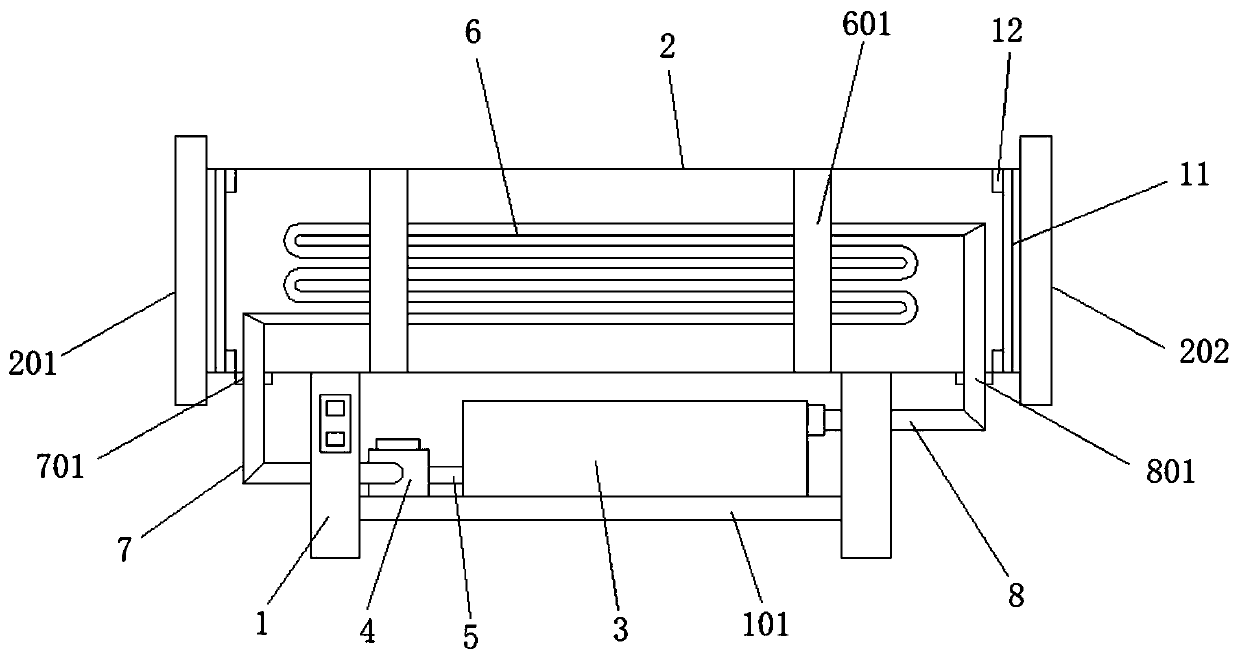

Pipeline cooling device for petrochemical plant

InactiveCN110953431AReduce the temperatureTo meet the needs of usePipe heating/coolingPipe elementsThermodynamicsPetrochemical

The invention discloses a pipeline cooling device for a petrochemical plant and belongs to the technical field of cooling equipment. The device comprises supporting legs, a bracket, a petroleum pipe,a first flange and a second flange. The supporting legs are installed on the two sides of the surface of the bottom of the petroleum pipe; the bracket is mounted at one side of the supporting leg; thefirst flange plate is installed at one end of the petroleum pip; the second flange plate is installed at the other end of the petroleum pipe; a cooler is installed on the surface of the top of the bracket; a water pump is installed at one side of the cooler; the input end of the water pump is connected with the output end of the cooler through a guide pipe; and a stainless steel coil is installedin an inner cavity of the petroleum pipe. Through mutual cooperation of the water pump and the cooler, cold water can be conveyed into a stainless steel coil pipe, so that petroleum in the petroleumpipe can be subjected to heat exchange; meanwhile, heat dissipation fins can volatilize heat on the surface of the outer wall of the petroleum pipe,; and the stainless steel coil pipe can be protectedthrough a filter screen plate, so that normal operation of pipeline cooling is facilitated.

Owner:陕西博睿信息科技有限公司

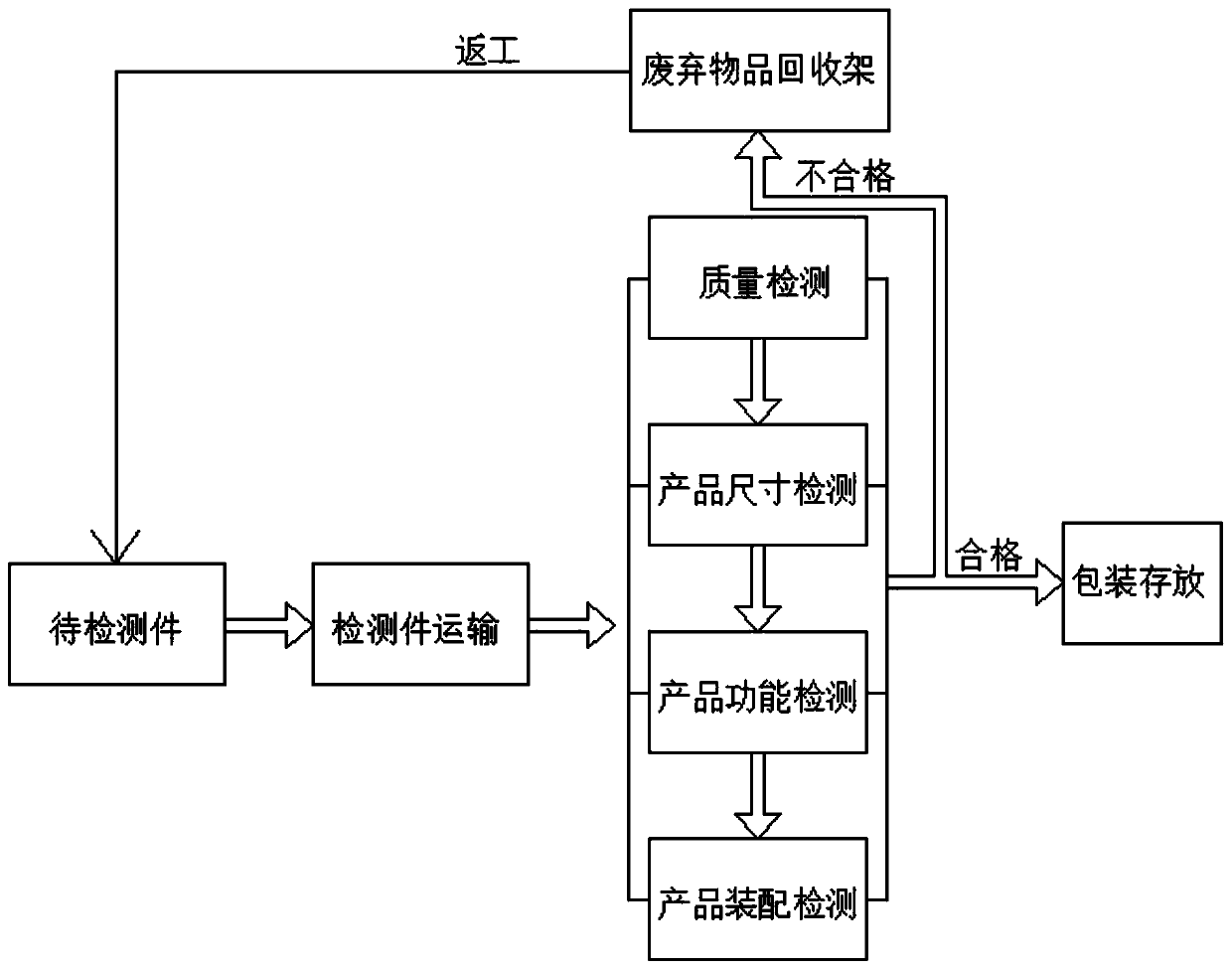

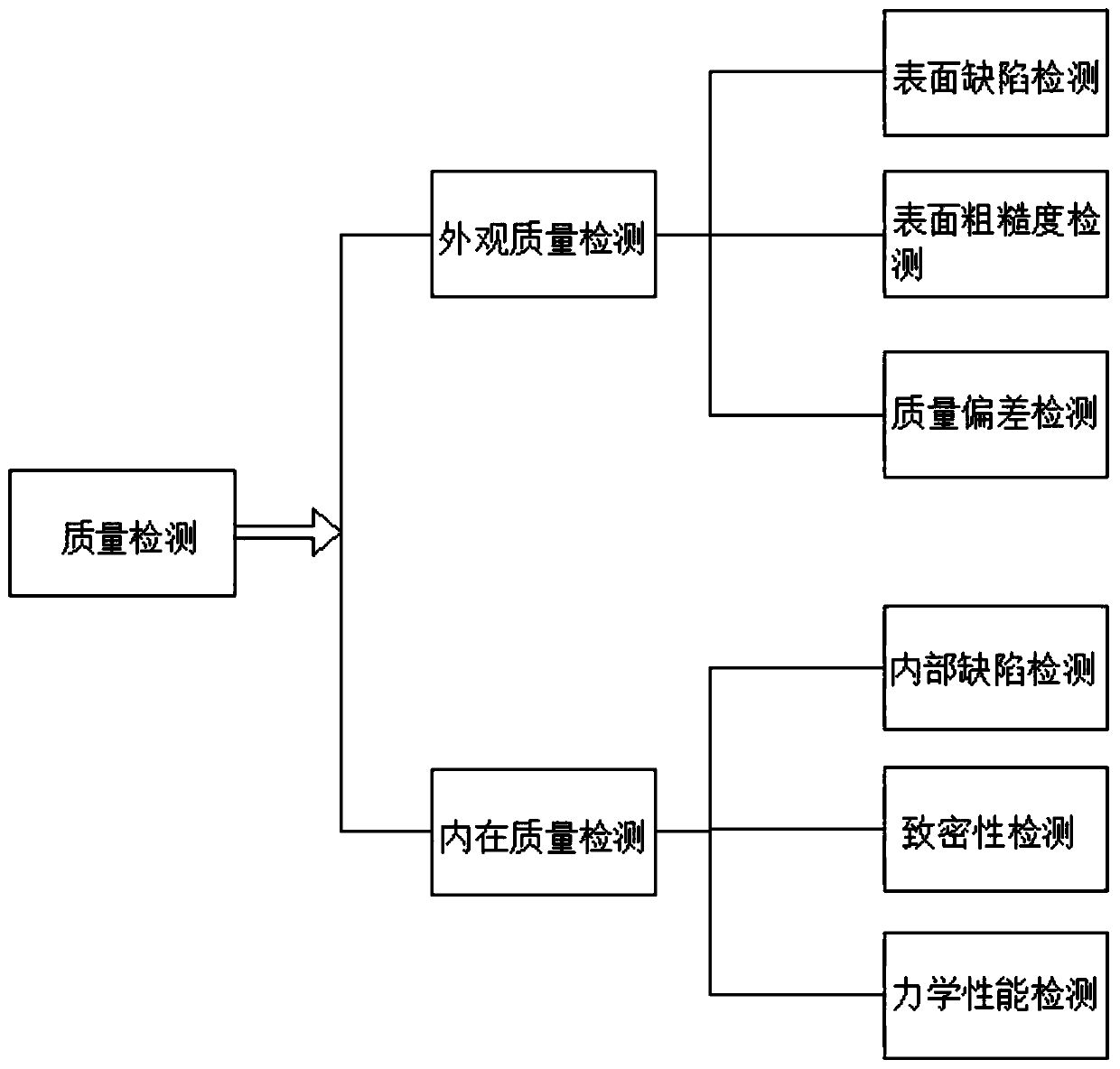

Product production quality inspection process flow

InactiveCN110261389AAccurate product testingSatisfied for long time useAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationManufacturing engineeringMarket competition

The invention discloses a product production quality inspection process flow. The product production quality inspection is performed by five steps, thereby ensuring the overall product quality state. When each to-be-detected product is detected, appearance quality inspection is performed to identify the appearance quality of the existing product and internal quality inspection is performed to detect the internal quality state of the product well; and thus because of appearance quality inspection and the internal quality inspection for product inspection, the product is detected accurately and thus a phenomenon that the defective product is not detected in one batch of products is avoided, so that the application need can be met well when the product is used externally. The long-time application demand can be satisfied; the product batch quality can be improved; and the service life of the product is prolonged. Therefore, the process flow has the high competitiveness in the market competition.

Owner:苏州铭优泽精密机械有限公司

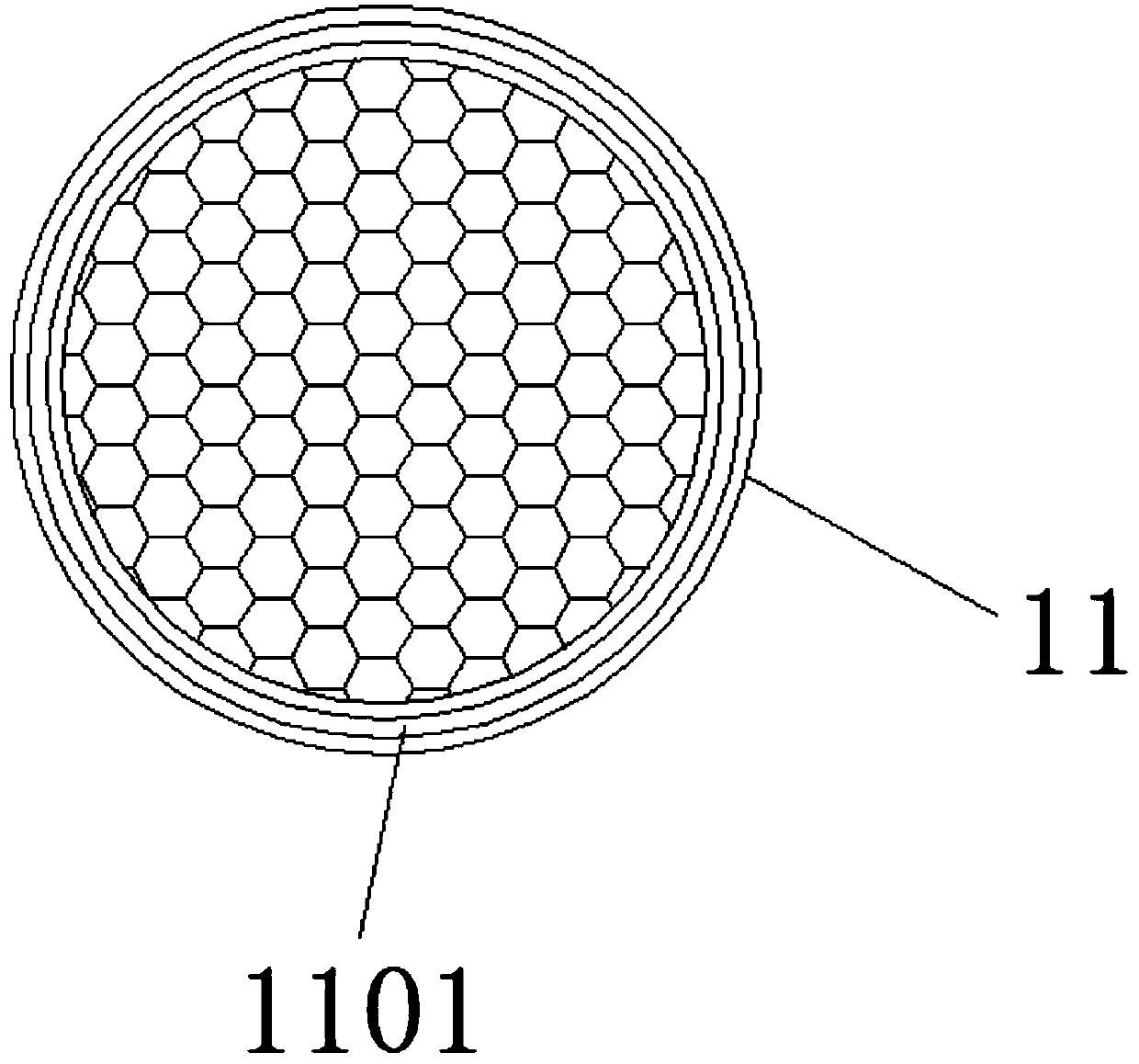

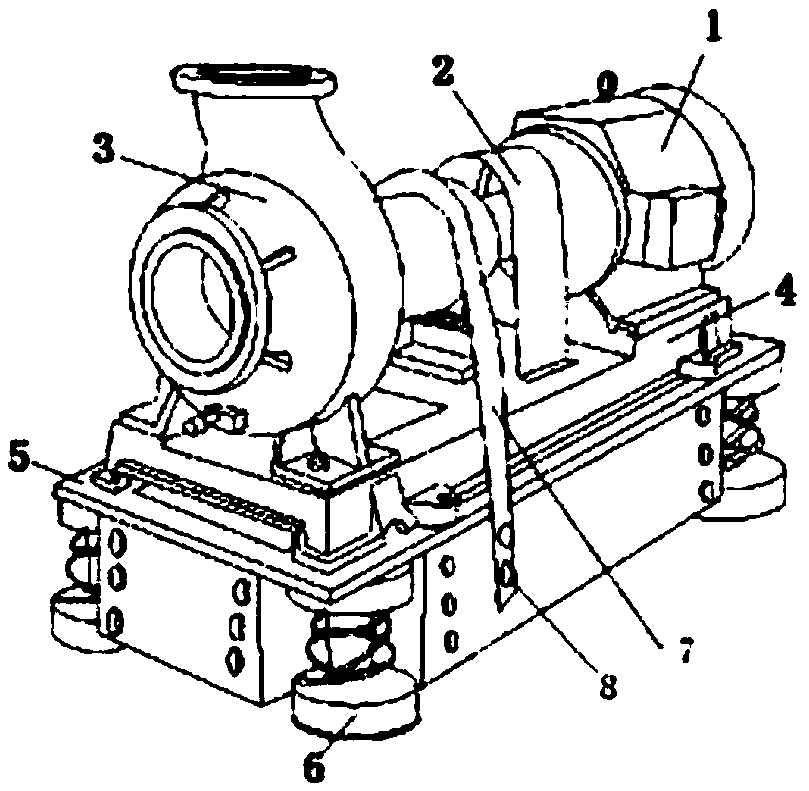

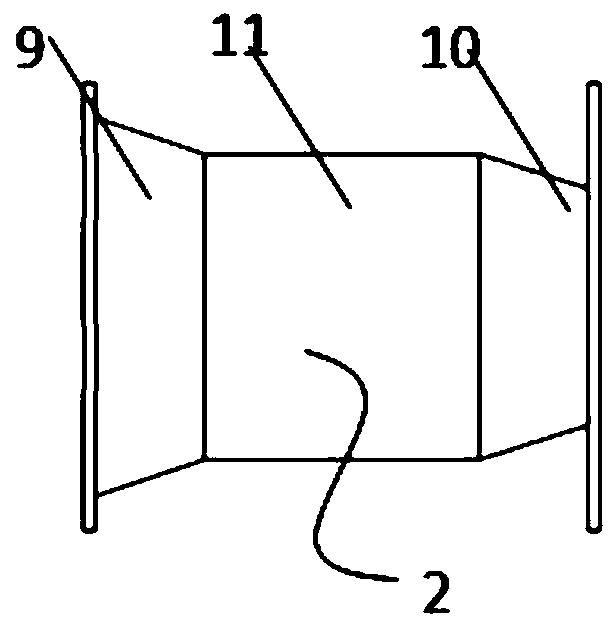

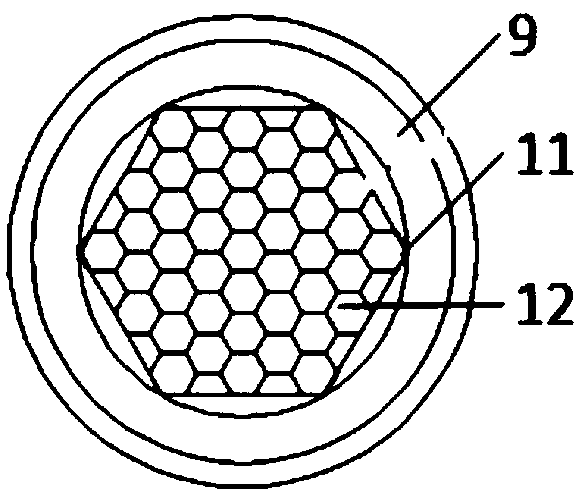

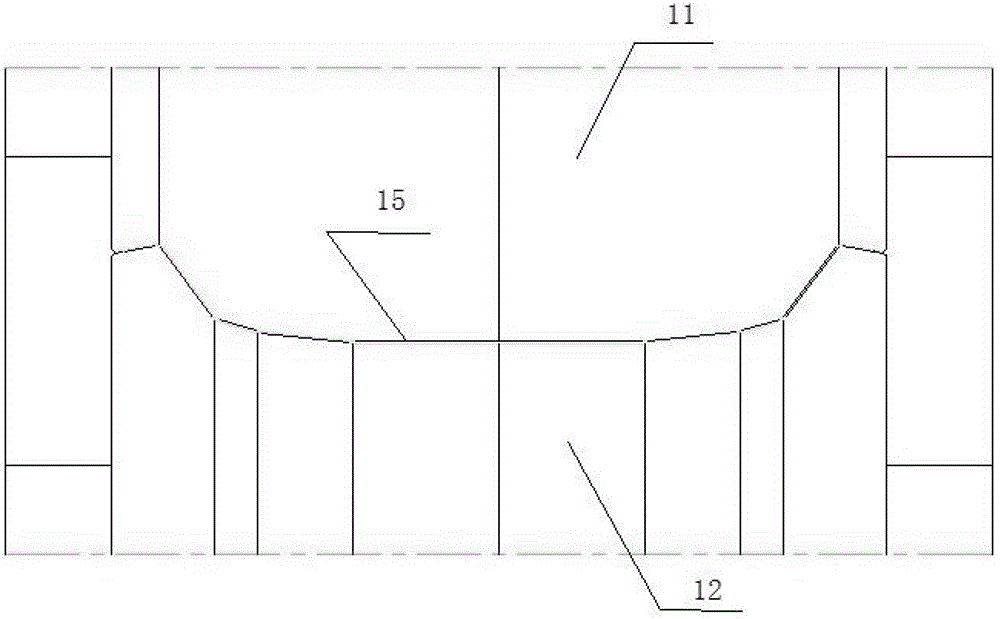

Rectifying booster water pump

The invention provides a rectifying booster water pump. The rectifying booster water pump comprises a pump shell and an inlet pipe, and an accommodating cavity is formed in the pump shell. The accommodating cavity is internally provided with a pump machine, and a pump motor is connected with the pump machine for providing kinetic energy for the pump machine, wherein the output end of the motor isconnected to a drive shaft. One end of the drive shaft extends out of the pump shell, and an impeller is arranged at the other end of the drive shaft, wherein the impeller rotates along with the rotation of the drive shaft. The inlet pipe is internally provided with an inlet rectification energy-saving device, and a rectifying shell includes a first shell and a second shell, wherein the first shell and the second shell are formed through a rectifying passage. The first shell and the second shell both have a trapezoidal cross section, and an inner cavity of the rectifying passage is a large regular hexagon composed of a plurality of small regular hexagons. After water in the rectifying booster water pump passes through the rectification device, the loss of pressure is not increased, the energy for forming a vortex is saved, and the vibration noise of the water pump is lower.

Owner:江苏海辽科技有限公司

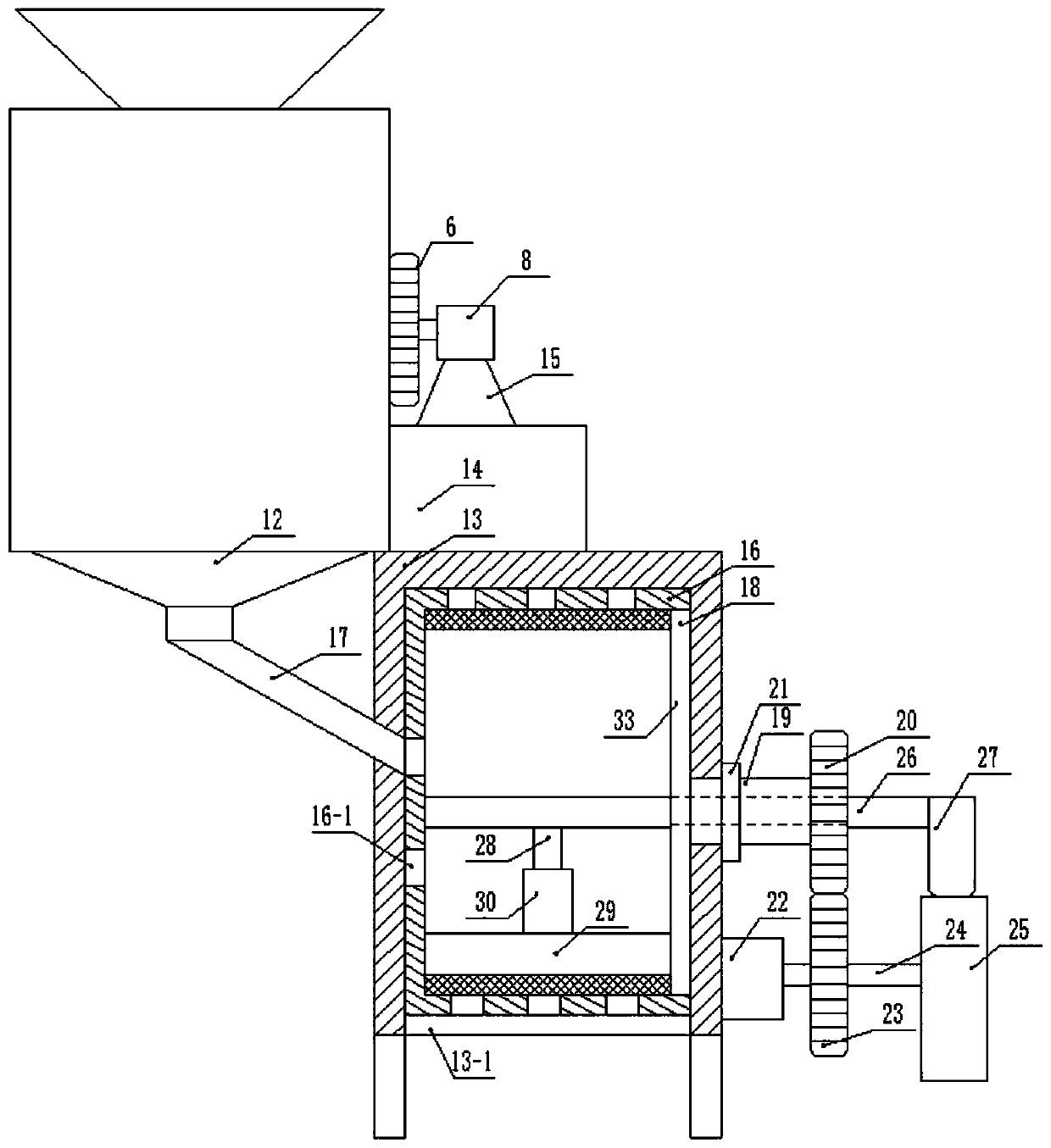

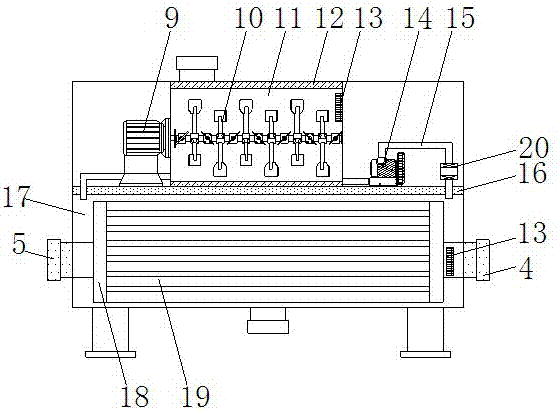

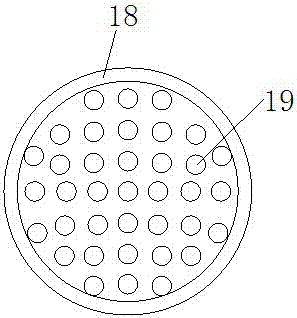

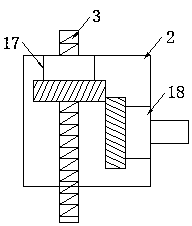

Lubricating grease heating equipment

PendingCN107990550AUniform temperatureHeating fastStorage heatersStationary tubular conduit assembliesElectricityHeat conducting

The invention discloses lubricating grease heating equipment. The lubricating grease heating equipment comprises a machine case, a motor, a stirrer, an electric heating wire, a heating box and heat conducting copper pipes. A heat conduction oil inlet is formed in the left side of the upper end face of the machine case, the bottom of a heat conduction oil heating box is fixed to the middle of the upper end face of a partition plate, the partition plate is fixed in the middle of the interior of the machine case, and the electric heating wire is arranged on the inner wall of the heat conduction oil heating box. The stirrer is arranged in the heat conduction oil heating box, the motor is arranged on the left side of the heat conduction oil heating box, and an oil pump is arranged on the rightside of the heat conduction oil heating box. An oil inlet of the oil pump is connected with the lower part of the right end face of the heat conduction oil heating box through an oil pipe, an oil pipeis connected to an oil outlet of the oil pump, and a partition bin on the left side of the heat conducting copper pipes communicates with a lubricating grease inlet in the lower portion of the left end face of the machine case. The lubricating grease heating equipment is provided with the machine case, the motor, the stirrer, the electric heating wire, the heating box and the heat conducting copper pipes, so that the traditional problems of uneven heating temperature and low temperature raising speed of lubricating grease are solved.

Owner:XINXIANG HENGXING TECH CO LTD

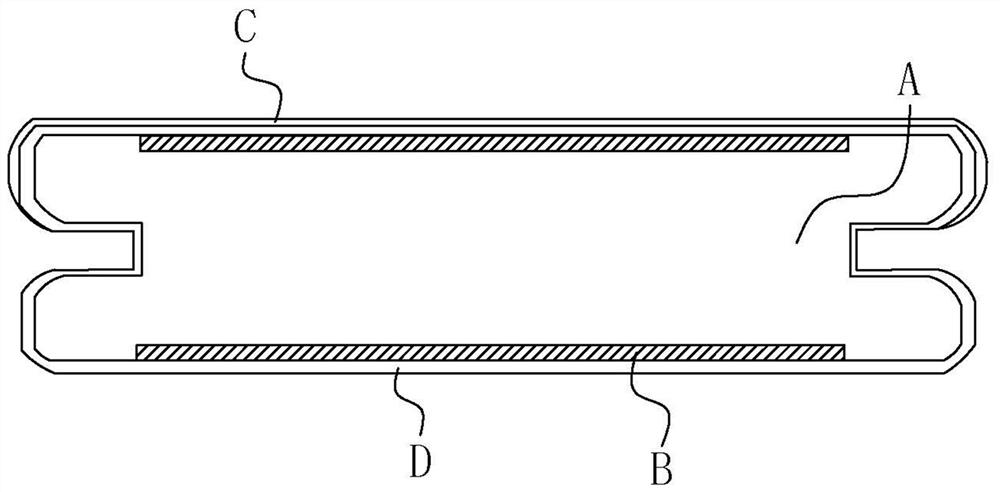

Reinforced foaming floor, and extrusion die and equipment set for preparation of reinforced foaming floor

ActiveCN113459454AHigh mechanical strengthHigh strengthSynthetic resin layered productsGlass/slag layered productsMechanical engineeringExtrusion

The invention relates to a reinforced foaming floor and an extrusion die and equipment set for preparing the reinforced foaming floor, and belongs to the technical field of co-extrusion foaming boards. The reinforced foaming floor comprises a foaming core body and reinforcing pieces; the reinforcing pieces are arranged in the foaming core body or on the surface of the foaming core body in a supporting mode; the number of empty holes in the section of the foaming core body is small; a plurality of separation runners conforming to the flowing direction of a core material are arranged in a core material runner of the extrusion die at intervals; and the equipment set comprises an extrusion die, a core material extrusion device, a reinforcing piece material conveying device, a limiting material extrusion device, a cooling shaping device, a traction device and the like. The prepared reinforced foaming floor has the advantages of high mechanical strength, good stability and low defective rate.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

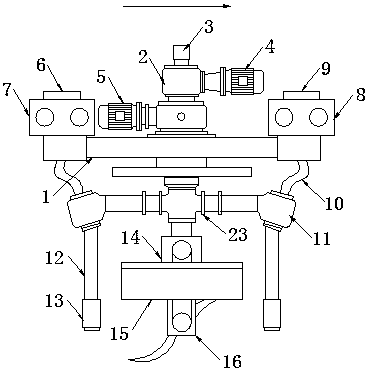

Sowing device for farmland

InactiveCN108521948AIncreased efficiency of nutrient absorptionCompact structurePlantingFurrow making/coveringAgricultural engineeringDrive motor

The invention discloses a sowing device for farmland. The sowing device comprises a frame, a lifting box, a lifting screw, a lifting motor, a reducer, a seed adding port, a seed storage tank, a fertilizer adding port, a fertilizer storage tank, a conveying pipe, booster pumps, feeding pipes, booster connectors, a drive motor, a support frame, transmission cases, a first turning gear, a second turning gear, a mounting part, a transmission rod, a tool rolling shaft, tools and a mounting rack. The sowing device has the advantages that the sowing device is compact in structure and convenient to use; the tools can be ascended and descended according to actual conditions, then pit digging depths can be adjusted, the sowing requirements of different regions and different soil texture can be satisfied, fertilizer is sprayed into soil before sowing, the tools roll to dig pits to allow the fertilizer to sufficiently contact with soil in the pits, and accordingly the nutrition absorption efficiency of seeds during sowing is increased greatly; sowing and fertilizing are integrated, the tool rolling shaft is uniform in stress and high in transmission efficiency, and the whole sowing device is high in stability and capable of effectively saving time and manpower.

Owner:龙岩丽荣电子科技有限公司

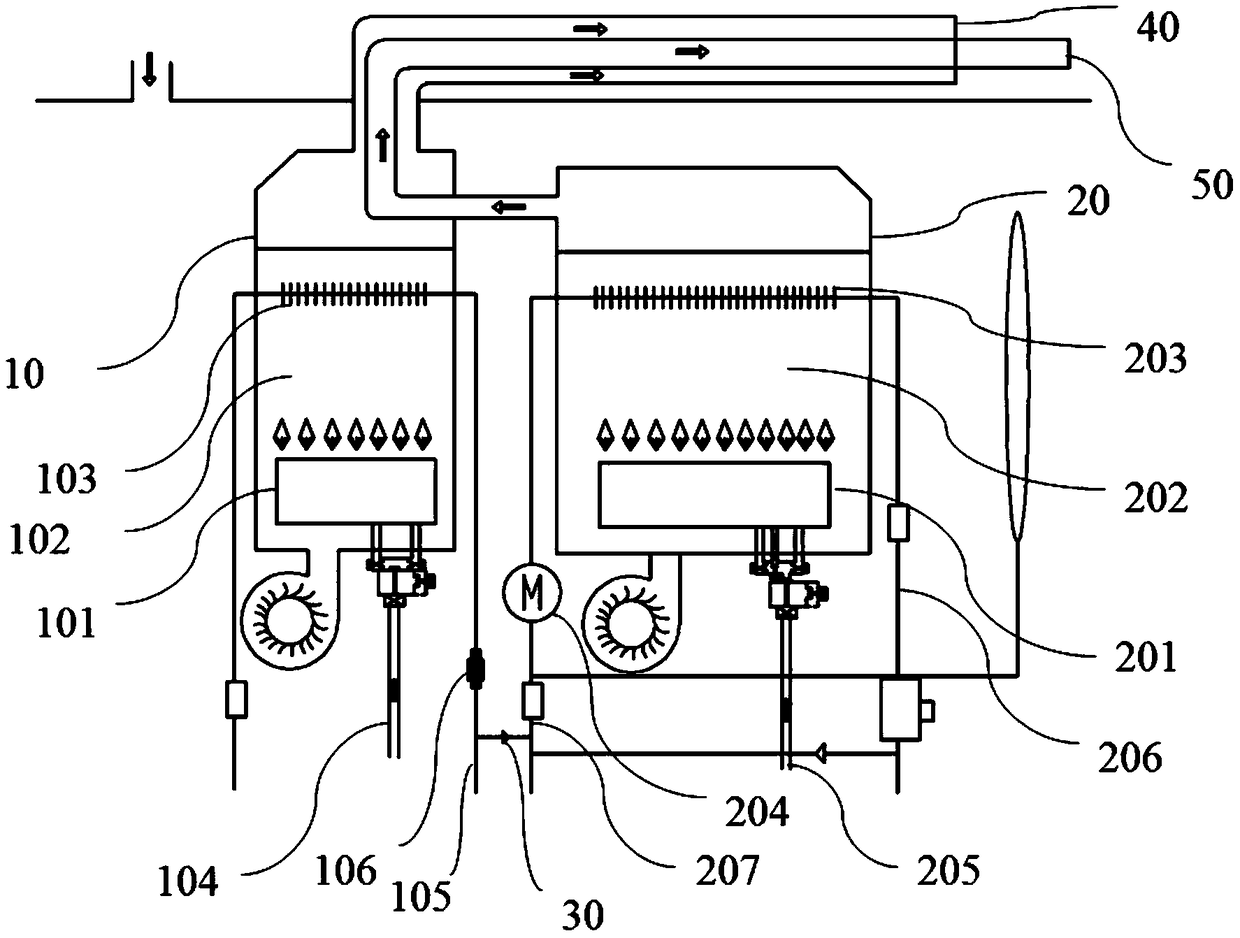

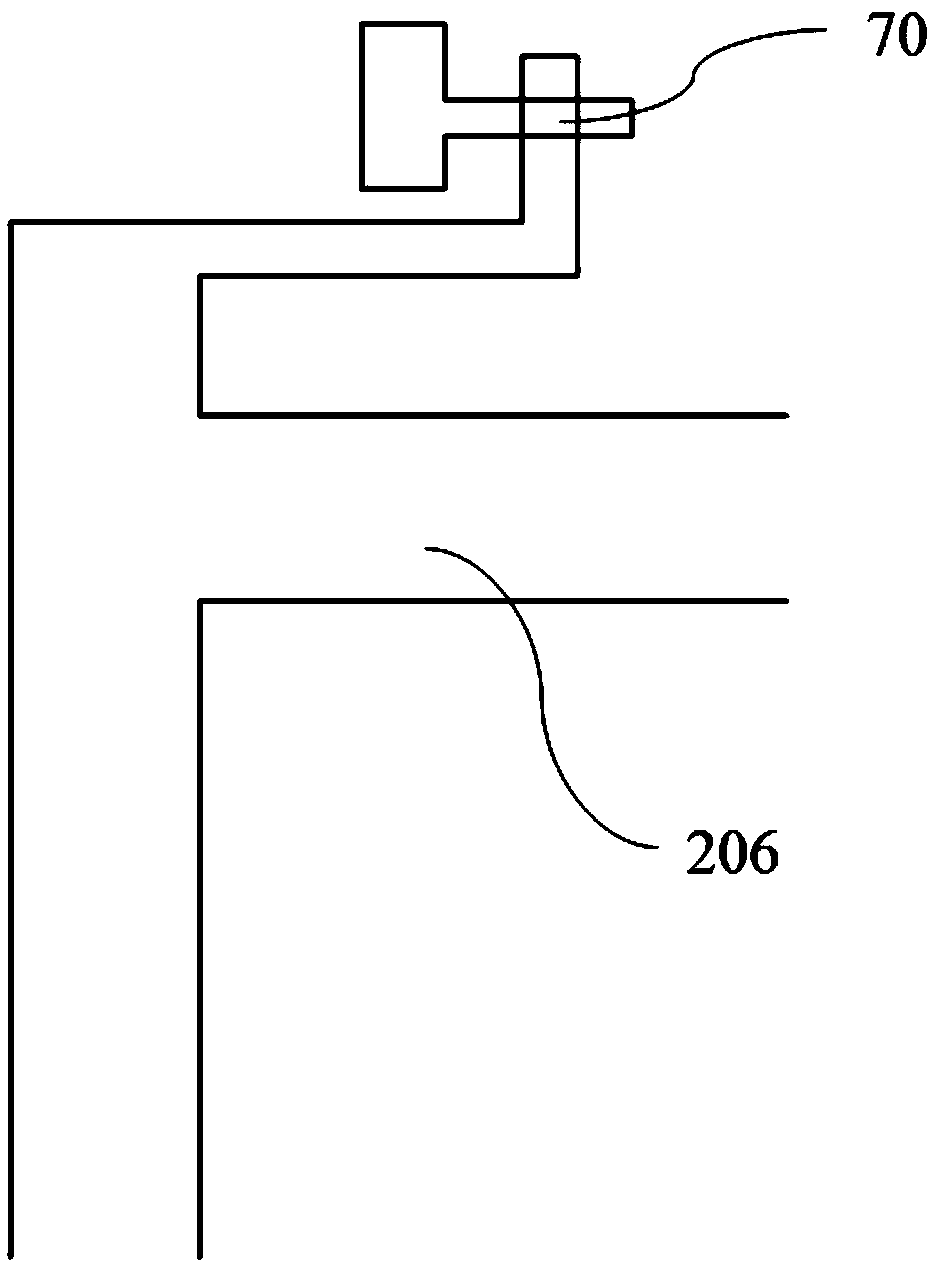

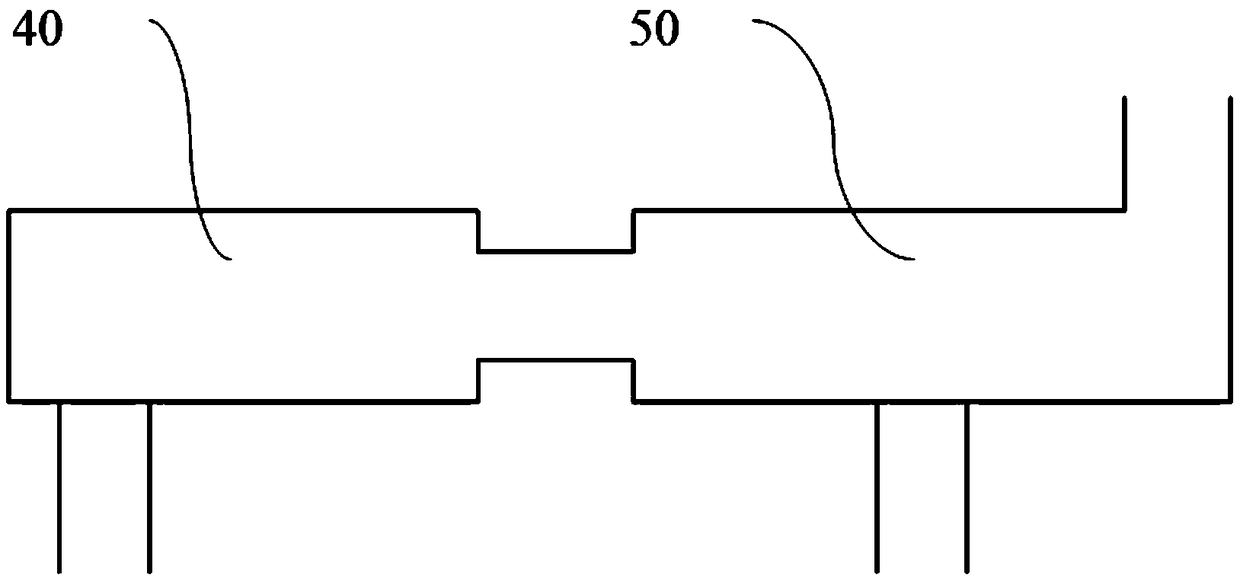

Double-gas device and gas water heater

PendingCN108645019ASimple structureEasy to manufactureWater heatersCombustion systemProcess engineering

The invention provides a double-gas device and a gas water heater, and relates to the field of gas water heaters. The double-gas device comprises a first gas device, a second gas device and a master controller. The double-gas device and the gas water heater have the advantages that the structure is simple, the manufacture is easy, by designing two sets of separate combustion systems, it can be achieved that hot water supply and heat supply are carried out simultaneously, the two sets of separate combustion systems can also be separately operated according to customer's demands to achieve separate heat supply and separate hot water supply, when heat supply and hot water supply are carried out simultaneously, the use demands of a user can be achieved, and the experience and feeling of the user are improved; and the energy consumption can be effectively reduced by adopting the two sets of separate systems.

Owner:GUANGDONG MACRO GAS APPLIANCE

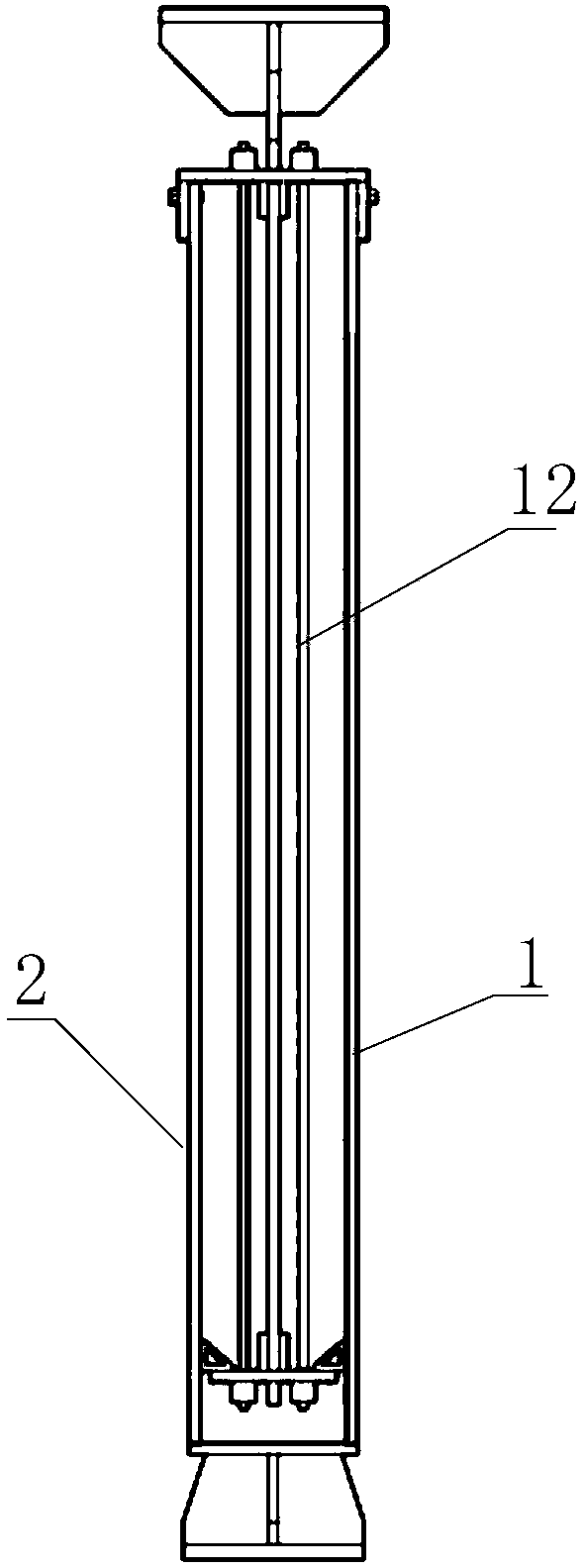

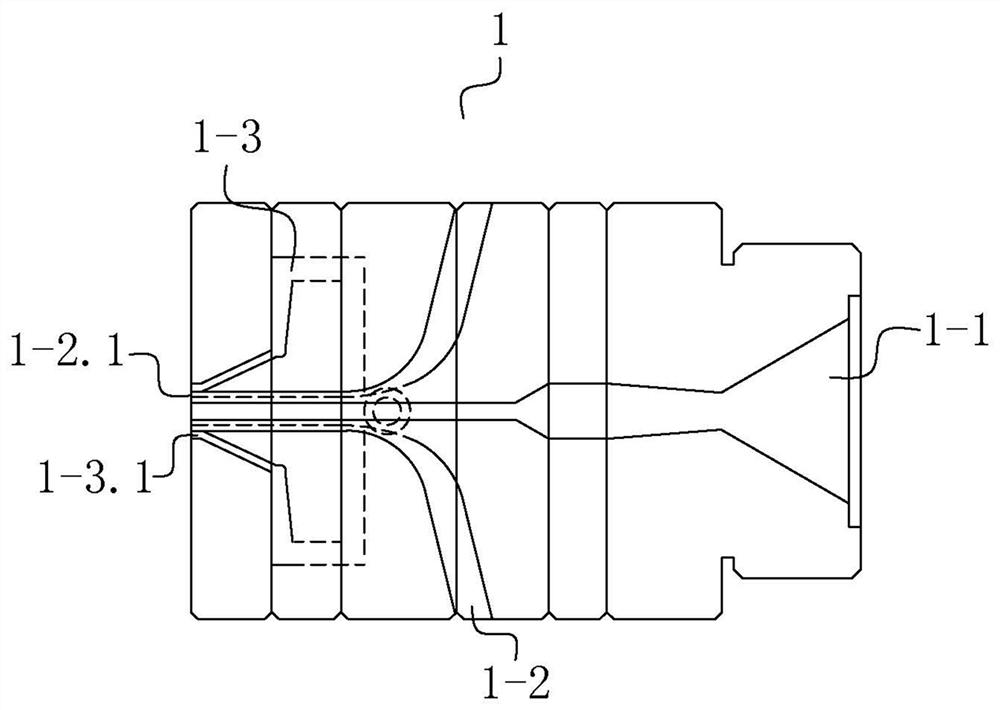

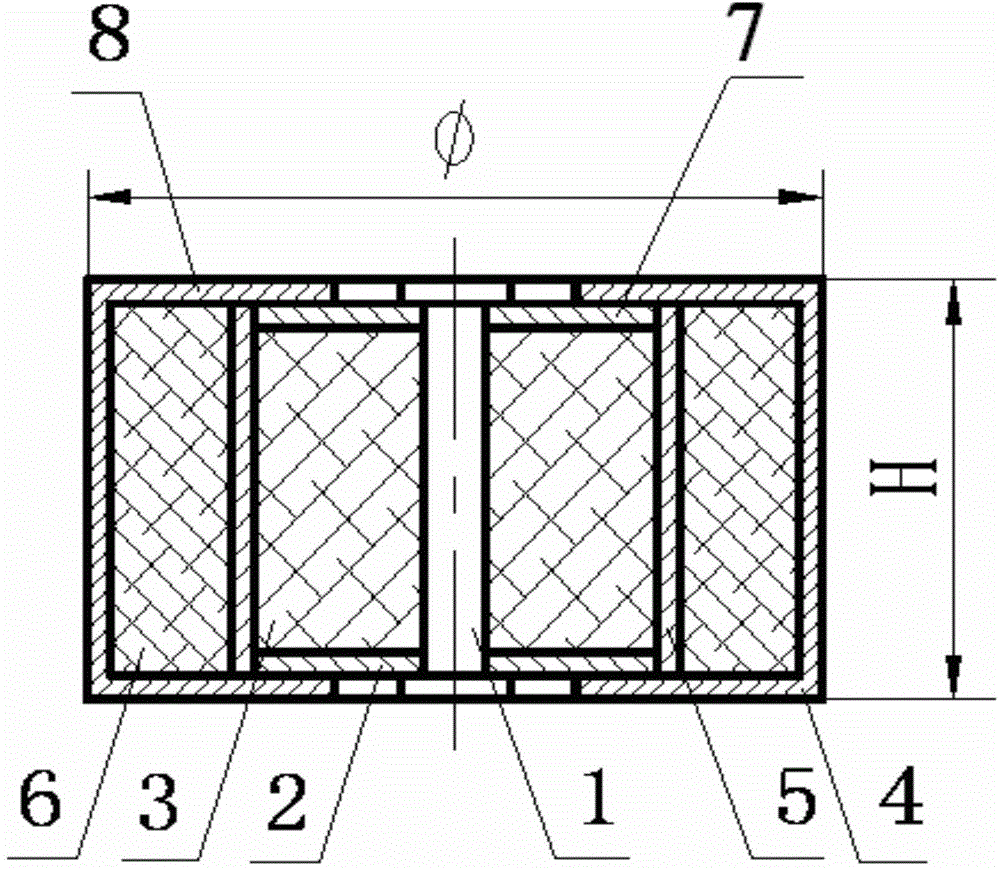

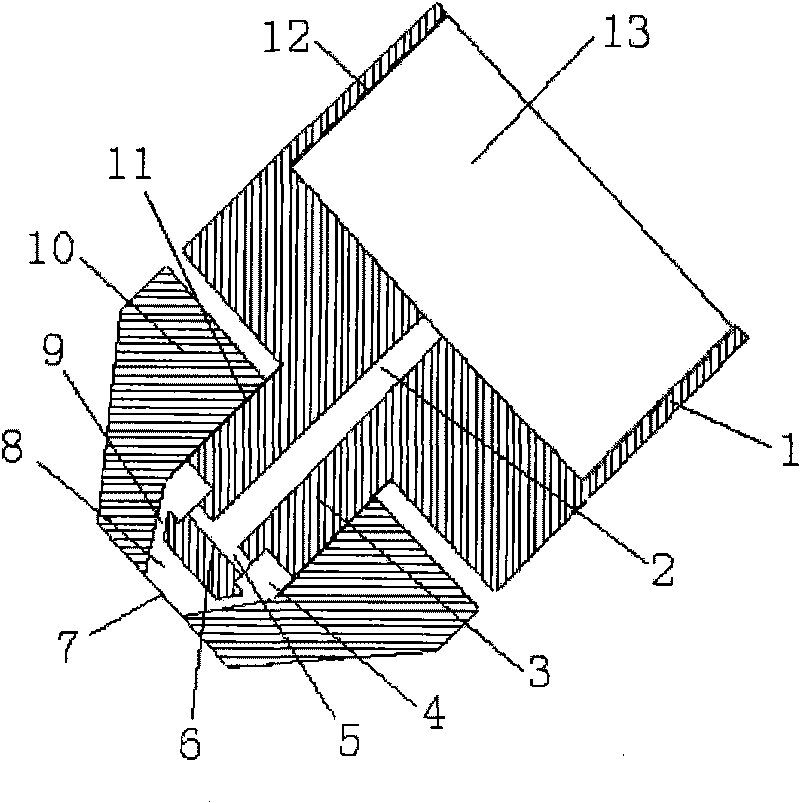

Single cylindrical multi-directional constant-stiffness all-metal vibration absorber

ActiveCN104100667AAdjust stiffnessConsistent stiffnessInertia effect dampersEngineeringVolumetric Mass Density

The invention provides a monomer cylindrical multi-directional constant-stiffness all-metal vibration absorber which comprises a mounting shaft, an axial lower end limiting stopper, an axial upper end limiting stopper, an axial vibration reduction medium, a first shell, a second shell, a radial limiting stopper and a radial vibration reduction medium, wherein the axial and radial vibration reduction components are of mutually independent structures; the axial vibration reduction component is cylindrical; the radial vibration reduction component is annular; the axial vibration reduction component is arranged in the radial vibration reduction component. By virtue of the unique design method of the vibration reduction components, multi-directional constant stiffness can be realized, the purpose of ensuring mutually-independent axial and radial stiffness regulation can be achieved, and the axial and radial resonant frequency intercoupling problem is radically solved; by virtue of controlling the densities of the vibration reduction media in the vibration reduction components, the resonant frequency points can be accurately controlled, the difference between the axial resonant frequency and the radial resonant frequency is controlled within + / -0.5Hz, and the usage requirements of vehicles, ships, airplanes and rockets in various occasions and the requirements for the multi-directional constant-stiffness vibration isolation and long-term storage of various instruments are met.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

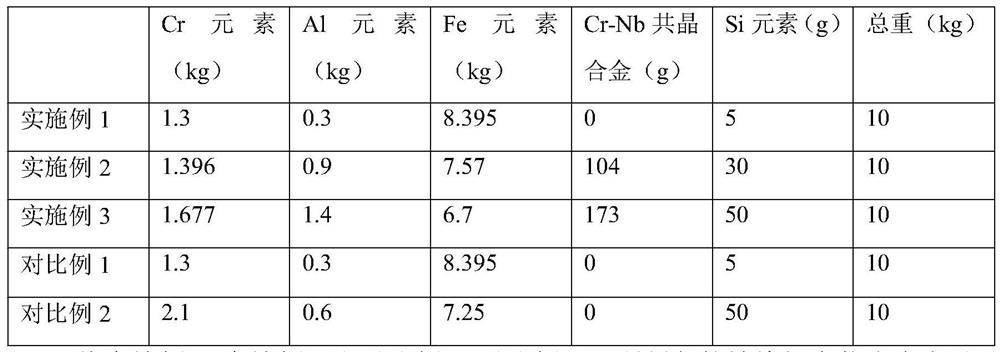

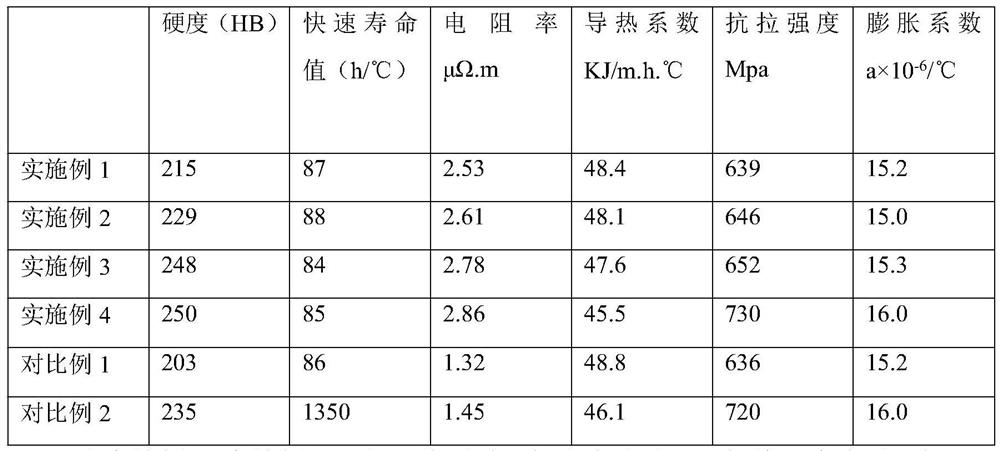

A preparation method of electrothermal alloy and the prepared electrothermal alloy material

ActiveCN111961952BHigh resistivityImprove performanceHeating element materialsElectric resistivitySemiconductor

The invention discloses a method for preparing an electric heating alloy, using the existing iron-chromium-aluminum electric heating alloy or a new iron-chromium-aluminum electric heating alloy as the target iron-chromium-aluminum electric heating alloy; and then casting the ingot of the target iron-chromium-aluminum electric heating alloy Rough rolling into a strip, after the strip is annealed, spray semiconductor powder on both sides of the strip; after the semiconductor powder is inlaid on both sides of the strip, finish rolling is carried out, and the finished electrothermal alloy product is obtained after finishing rolling forming treatment; By adjusting the composition of the alloy and adjusting the preparation process of the overall electrothermal alloy, the resistivity of the iron-chromium-aluminum electrothermal alloy can be significantly increased to meet the use requirements and bring new breakthroughs in the use of the electrothermal alloy, which has great economic significance and market value.

Owner:江苏佳腾新材料有限公司

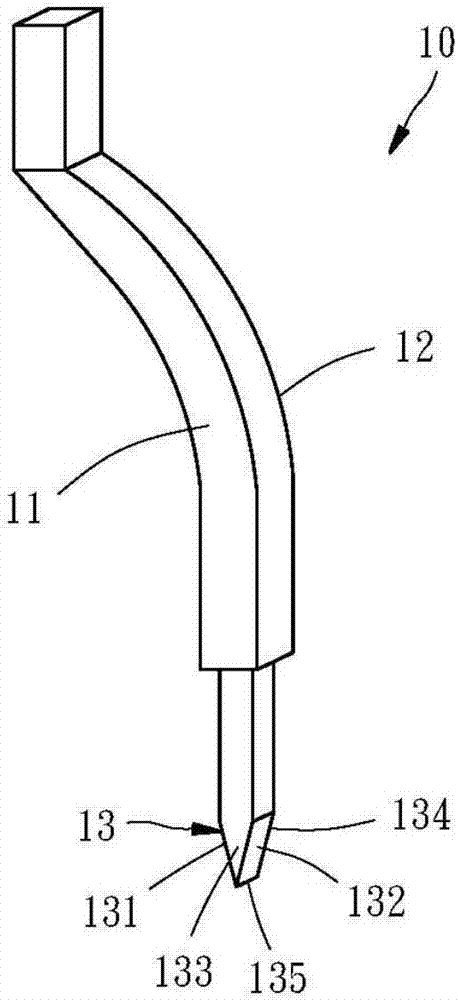

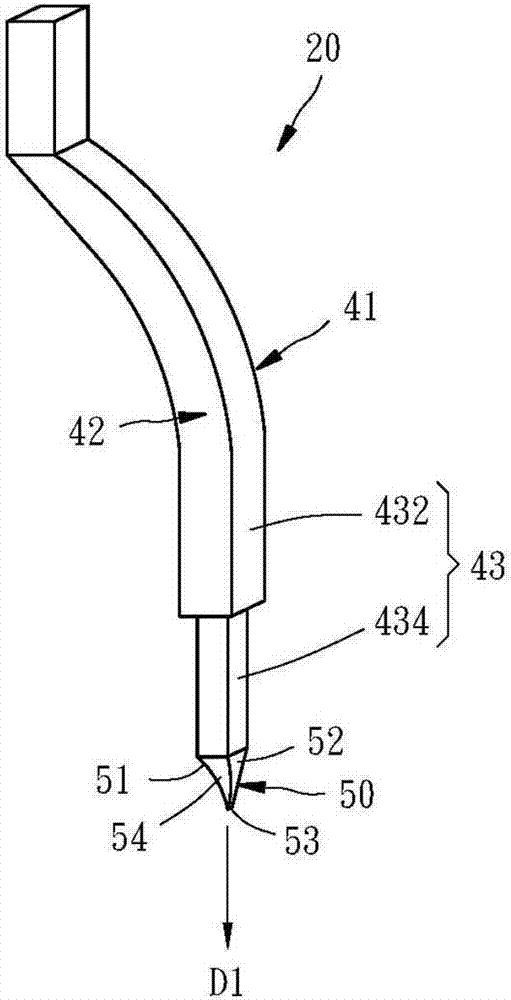

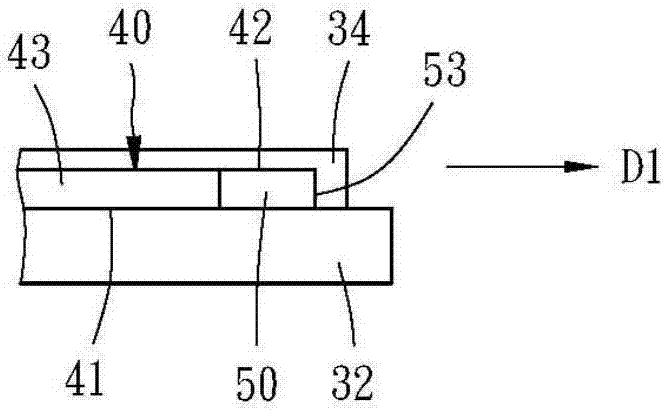

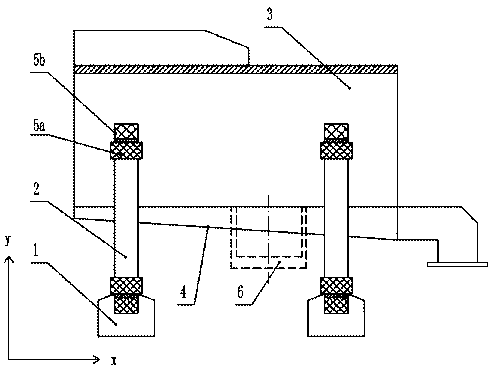

Microelectromechanical probe, method of manufacturing the same and probe set structure

InactiveCN106990271AReduce distanceTo meet the needs of useFixed microstructural devicesElectrical measurement instrument detailsEngineeringMicroelectromechanical systems

The invention relates to a microelectromechanical probe. A microelectromechanical probe is manufactured by a MEMS manufacturing process forming a probe body and a cutting process providing a pinpoint portion a cutting face. The probe has a top surface, a body portion, and a pinpoint portion which is substantially extended in a probing direction from the body portion and provided with first and second sides and a probing end substantially oriented in the probing direction. The cutting face is provided on the top surface and descending, adjoins the first and second sides and the probing end, and has at least one cut mark formed by the cutting process. The cut mark is substantially extended from the first side to the second side and non-parallel to the probing direction. The cutting face descends from an edge cut mark to the probing end. As a result, the probing end has a small area, thereby making small probe marks, easily piercing a passivation layer of a device under test, and having more recognizable images.

Owner:MPI CORP

Corrosion-resisting weldable aluminum alloy board for box tank car and manufacturing method of board

The invention relates to a corrosion-resisting weldable aluminum alloy board for a box tank car and a manufacturing method of the board. The board comprises materials including, by mass percent, 0.10 to 0.4% of Cu, 0.25 to 0.55% of Mn, 1.5 to 2.0% of Mg, 5.0 to 5.6% of Zn, 0.15 to 0.45% of Er and the balance Al. The method comprises steps of firstly, raw material weighing, secondly, aluminum melt preparing, thirdly, semi-continuous casting, fourthly, annealing, fifthly, rolling, sixthly, quenching, seventhly, straightening and eighthly, aging. The board surface quality is good, the combination mechanical property is excellent, the welding coefficient reaches 77%, and the welding coefficient is higher than that of an existing conventional heat-treatable hardening aluminum alloy, the tensile strength is not smaller than 443 MPa, the percentage elongation after fracture is not smaller than 3%, welding and machining forming performance is good, and post processing is facilitated.

Owner:NORTHEAST LIGHT ALLOY CO LTD

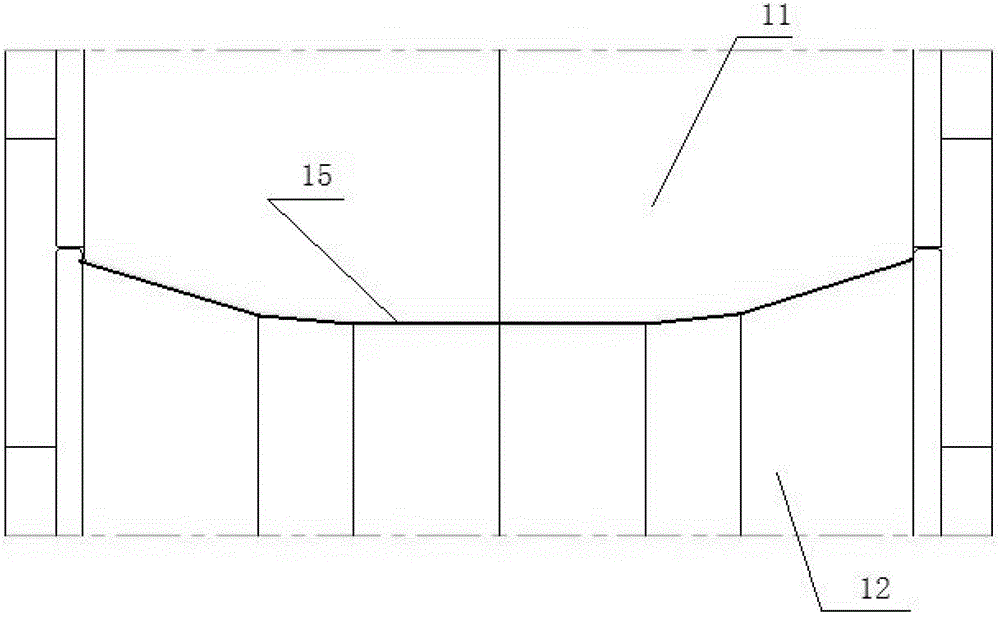

Foundry waste sand regeneration and shock absorption device

ActiveCN103350187AReduce vibrationImprove shock absorptionMould handling/dressing devicesFoundryEngineering

The invention belongs to the field of shock absorption devices and specifically relates to a foundry waste sand regeneration and shock absorption device. The foundry waste sand regeneration and shock absorption device disclosed by the invention comprises a base, wherein a plurality of support columns are arranged on the base, the support columns are connected with a filter screen, shock absorption springs along the directions of an X axis and a Y axis are overlapped on the support columns, and a vibration source in the direction of a Z axis is arranged at the bottom of the filter screen. The vibration source in the direction of the Z axis is opened to enable the filter screen to produce two-dimensional vibration; as the support columns are connected with the filter screen, and the shock absorption springs along the directions of the X axis and the Y axis are overlapped on the support columns, the two-dimensional vibration is promoted to become three-dimensional vibration; and simultaneously, as the shock caused by a pure hard mechanical structure is too severe, the noise is great, the operation of the device is non-smooth and the service life of the whole device is reduced by long-term usage, the shock absorption springs along the directions of the X axis and the Y axis are arranged on the support columns, and then the shock absorption principle of the shock absorption springs is utilized to reduce the vibration in the directions of the X axis and the Y axis, thus the noise is reduced, the operation is smooth, and the service life of the whole device is prolonged.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

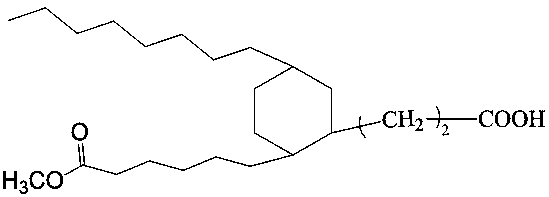

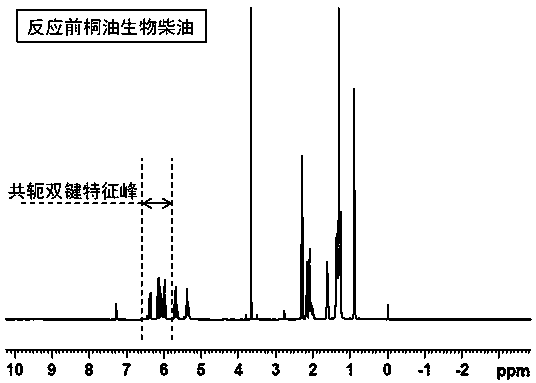

Improving agent for improving low-sulfur diesel lubricating property and synthetic method of improving agent

ActiveCN109486504AReduce sulfur contentImprove the lubrication effectBiofuelsLiquid carbonaceous fuelsBiodieselDistillation

The invention relates to an improving agent for improving low-sulfur diesel lubricating property and a synthetic method of the improving agent. The method includes the steps: adding unsaturated monocarboxylic acid into a premixing tank of an impinging stream reactor, and heating the unsaturated monocarboxylic acid to reach the temperature of 80-100 DEG C; slowly leading tung oil biodiesel into thepremixing tank, conveying mixed liquid in the premixing tank into a feeding port of the impinging stream reactor by a circulating pump, enabling the mixed liquid to flow to a material impinging areathrough a flow guide cylinder at high speed to perform impinging reaction, controlling reaction temperature to be 110-150 DEG C, enabling the materials after impinging to reflow the premixing tank from discharging ports in two sides, conveying the materials into the feeding port of the reactor by the circulating pump to perform continuous operation, and continuing to run for a certain time after the tung oil biodiesel is completely added; performing pressure reduction distillation on the materials after reaction to obtain an improving agent product. The synthesized improving agent can improveabrasion resistance of low-sulfur diesel and low in condensation point, the blending proportion of the improving agent and the low-sulfur diesel is low, and the blended low-sulfur diesel can meet state V lubricating standards.

Owner:CHINA PETROLEUM & CHEM CORP +1

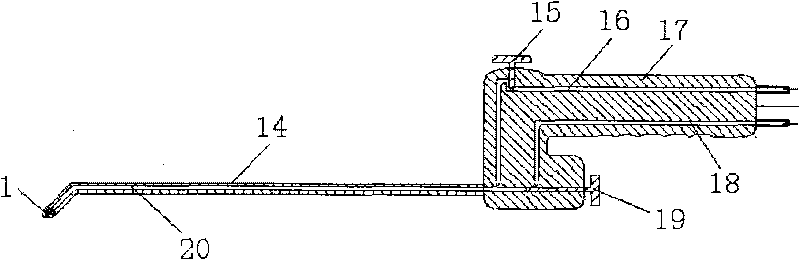

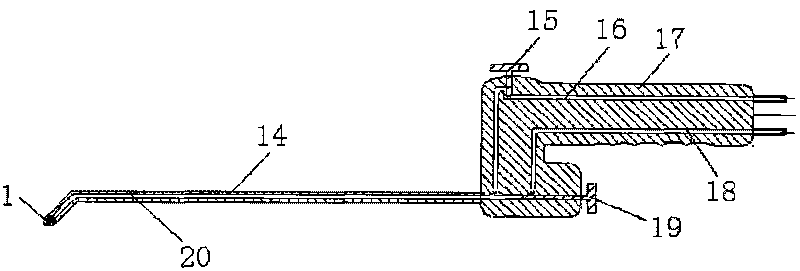

Atomizing nozzle and hand-hold atomization gas quenching device with atomizing nozzle

InactiveCN101709361ATo meet the needs of useEasy to useQuenching agentsQuenching devicesHand heldEngineering

The invention provides an atomizing nozzle and a hand-hold atomization gas quenching device with the atomizing nozzle, comprising a handle which is internally provided with a gas channel and a liquid channel, and a spraying pipe which is internally provided with a mixed gas channel which is communicated with the gas channel and the liquid channel, and is connected with the handle; the hand-hold atomization gas quenching device is characterized in that: the atomizing nozzle is connected at the end part of the spraying pipe and is provided with a nozzle body with a channel and a rotating head which is matched with the nozzle body and is provided with a cavity and a jet opening; the original way that the gas quenching or the liquid quenching is carried out independently is changed into the way that the gas quenching and liquid quenching are carried out at the same time, thereby having the advantages of liquid quenching and gas quenching; in addition, the device does not need a huge supporting facility and is only matched with a small device, so as to save a great amount of cost and investment for users; in addition, the carrying and usage are convenient, therefore, the hand-hold atomization gas quenching device with the atomizing nozzle is an ideal quenching device.

Owner:KUNMING UNIV OF SCI & TECH

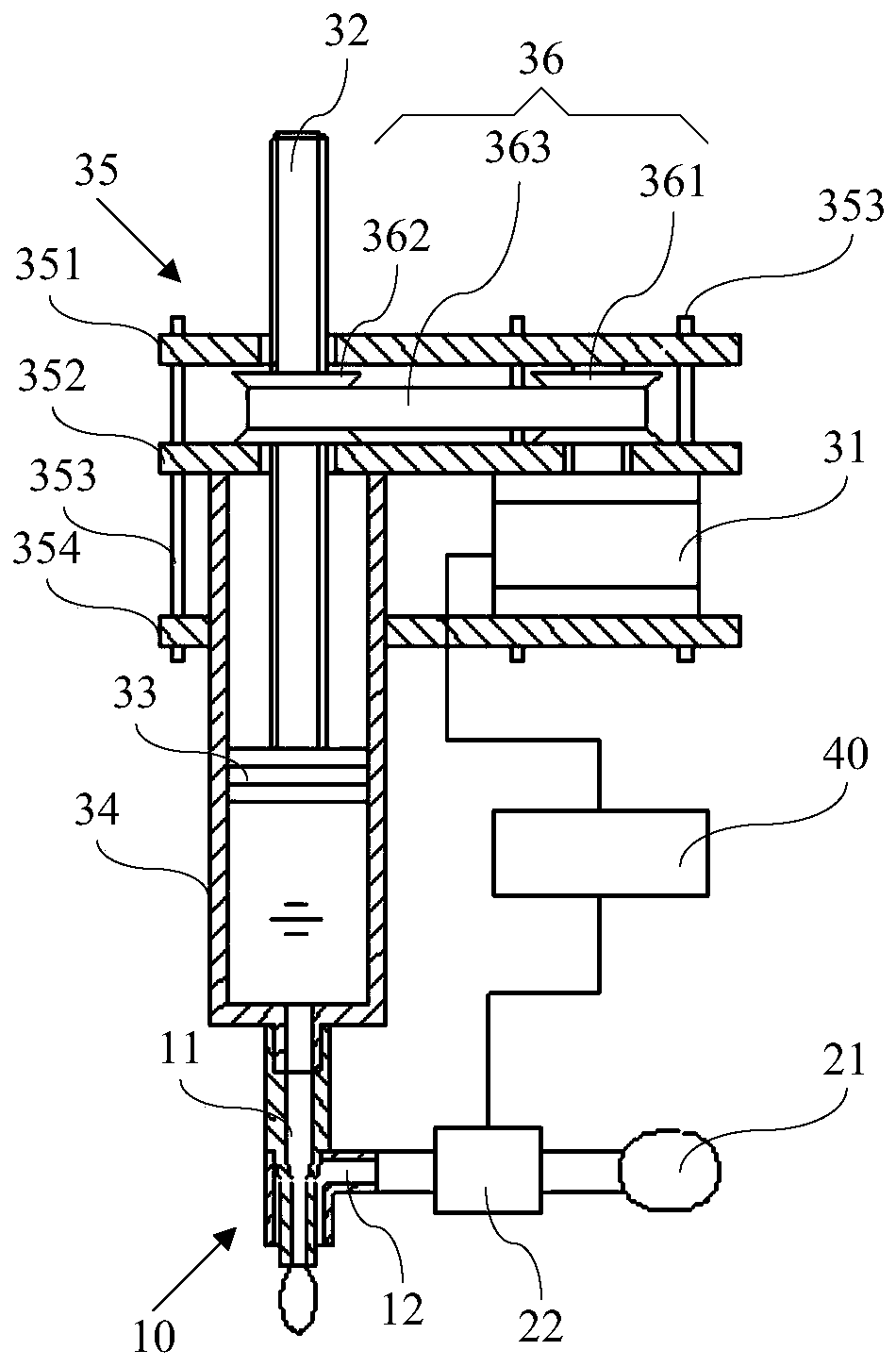

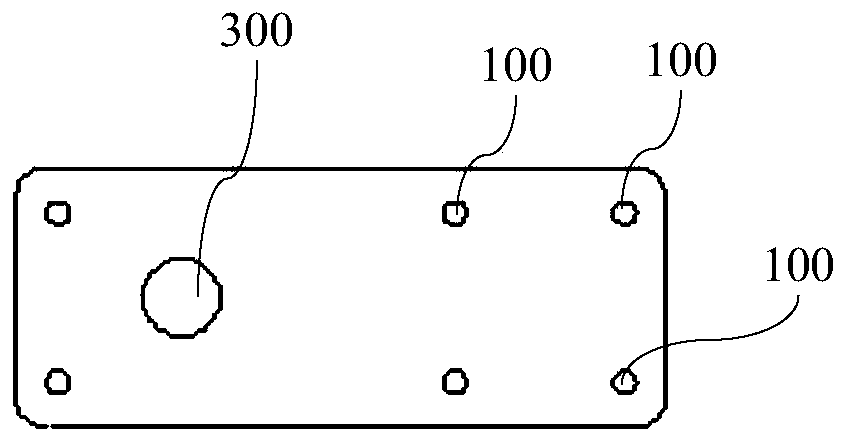

Liquid drop subdivision device and method

PendingCN110038745AExtrusion stabilityGood size consistencyLiquid spraying apparatusEngineeringSyringe needle

The invention discloses a liquid drop subdivision device and method and belongs to the technical field of liquid treatment. The device comprises a syringe needle, an air source, an air valve, a control motor, a screw rod, a transmission mechanism, a piston, a cylinder barrel, a supporting frame and a controller, wherein an input port of the air valve communicates with the air source, and an outputport of the air valve communicates with a first input port of the syringe needle; the control end of the air valve and the control end of the control motor are electrically connected with the controller correspondingly; an output shaft of the control motor is in screw driving with the first end of the screw rod through the transmission mechanism, and the second end of the screw rod is fixedly connected with the piston; the cylinder barrel and the transmission mechanism are arranged on the supporting frame; the portion between the first need and the second end of the screw rod penetrates through the first end of the cylinder barrel; the second end of the cylinder barrel communicates with a second input port of the syringe needle; and the piston is slidably arranged in the cylinder barrel.The liquid drop subdivision device and method can meet the using requirements of users.

Owner:JIANGHAN UNIVERSITY

Graphene and its production method, application and battery

ActiveCN108545724BReduce manganese contentReduce processingCell electrodesGrapheneMetal impuritiesLithium-ion battery

The present invention provides a kind of graphene and production method thereof, use and battery, relate to graphene technical field, the production method of this graphene comprises the following steps: A) after the oxidation reaction of graphite with concentrated sulfuric acid and potassium permanganate, Carry out solid-liquid separation to recover concentrated sulfuric acid, and obtain the first-level graphene oxide solid; B) the first-level graphene oxide solid is removed by hydrogen peroxide and the second-level graphene oxide solid is obtained after solid-liquid separation, and then washed with hydrochloric acid and then water Washing to obtain refined graphene oxide, and the refined graphene oxide is reduced to obtain graphene. Utilizing this production method can alleviate the high metal impurity content of graphene obtained by the existing graphene production process, which is not suitable for lithium-ion battery materials and the amount of sewage caused by purification treatment is large, which is likely to cause technical problems such as pollution mitigation, so as to achieve the reduction of graphene. purpose of metal content.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

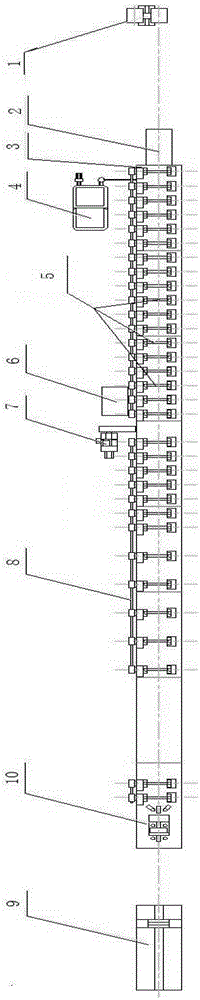

Roll forming equipment and implementation method for B-shaped profile

InactiveCN103230934BPrecision rollingCause scratchesMetal rolling arrangementsDrive shaftEngineering

The invention belongs to the field of profile processing and manufacturing and particularly relates to equipment for forming a profile with a B-type cross section and an implementation method thereof. The equipment comprises an uncoiling machine, a feeding system, a rolling machine body, a roller transmission shaft, a power distribution box, a power system and a profile cutting and sawing machine, and is characterized by further comprising roller forming systems in multiple passes, wherein the roller forming systems are driven by the power system and the roller transmission shaft; the roller forming system in each pass comprises upper and lower rollers and left and right rollers; the upper and lower rollers in each pass are matched in shape and used for rolling the processed profile to form profile sections with B-type cross sections; the left and right rollers are symmetrically arranged and both provided with profile forming openings; the profile forming openings of the left and right rollers in the multiple passes are arranged in sequence; and the left and right rollers are used for turning the profile sections with the B-type cross sections of the processed profile to form a B shape. By setting the roller forming systems in the multiple passes, the profile can be accurately rolled to form a B-type profile.

Owner:BEIJING DOOR & WINDOW DEVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com