Improving agent for improving low-sulfur diesel lubricating property and synthetic method of improving agent

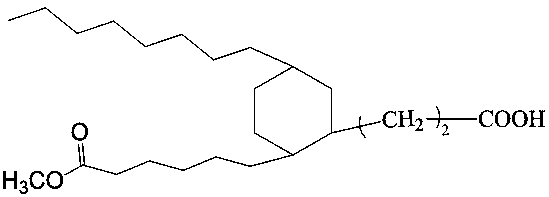

A low-sulfur diesel oil and synthesis method technology, applied in the field of oil additives, can solve problems such as diesel engine corrosion, achieve the effects of increasing entanglement density, expanding application range, and improving lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

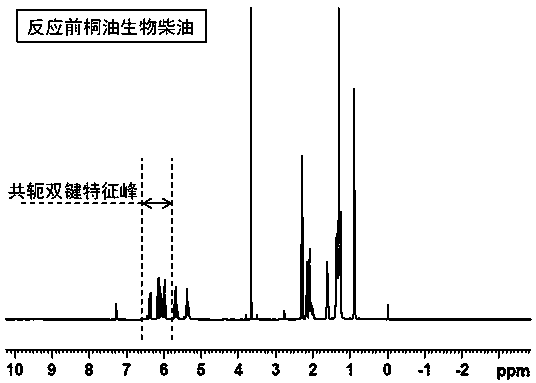

[0036] Preparation of tung oil methyl ester: Add 800g tung oil, 160g methanol, and 8g potassium hydroxide into a 2L high-pressure reactor, and carry out stirring reaction. The reaction temperature is 60°C, and the reaction time is 20min. Glycerin product 76.2g, then the upper layer product was washed 3 times with 50°C hot water, and the washed product was distilled at 2000Pa and 60°C for 2h to obtain tung oil methyl ester biodiesel.

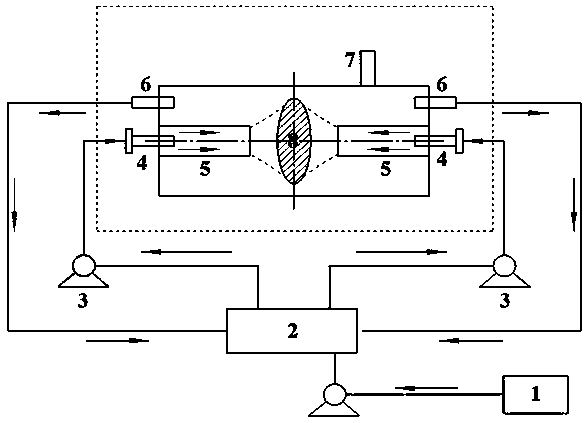

[0037] Put 250g of 4-pentenoic acid into the premix tank of the impingement flow reactor, and heat up to 90°C; then slowly feed tung oil methyl ester biodiesel 500g into the premix tank, and control the feed rate to the volume of the premix tank 0.5 times (that is, the feed volume space velocity is 0.5h -1 ), and at the same time, the mixed liquid in the premixing tank is delivered to the feed port of the impinging flow reactor through the circulating pump, and the rate of the circulating material is controlled to be 1.0 times the volume of the i...

Embodiment 2

[0042] The preparation process and operating conditions are the same as in Example 1, except that the feed rate of tung oil methyl ester is 1.0 times the volume of the premix tank (that is, the feed volume space velocity is 1.0h -1 ), while controlling the circulating material rate to be 2.0 times the volume of the impinging flow reactor (that is, the circulating material volume space velocity is 2.0 h -1 ), after the tung oil biodiesel was added, the reaction was continued at 130°C for 0.5h to obtain the improver product B, and the reaction molecular conversion rate was 92.6%. After testing, the acid value of the product is 129.8mgKOH / g, and the freezing point is -27.0°C.

Embodiment 3

[0044] The preparation process and operating conditions are the same as in Example 1, except that the feed rate of tung oil methyl ester is 0.2 times the volume of the premix tank (that is, the feed volume space velocity is 0.2h -1 ), while controlling the circulating material rate to be 0.5 times the volume of the impinging flow reactor (that is, the circulating material volume space velocity is 0.5h -1 ), after the tung oil biodiesel was added, the reaction was continued at 130°C for 2 hours to obtain the improver product C, and the reaction molecular conversion rate was 96.4%. After testing, the acid value of the product is 133.5mgKOH / g, and the freezing point is -27.5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com