Soil crushing device

A soil pulverizing and pulverizing roller technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of low work efficiency, many procedures, and high labor intensity, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

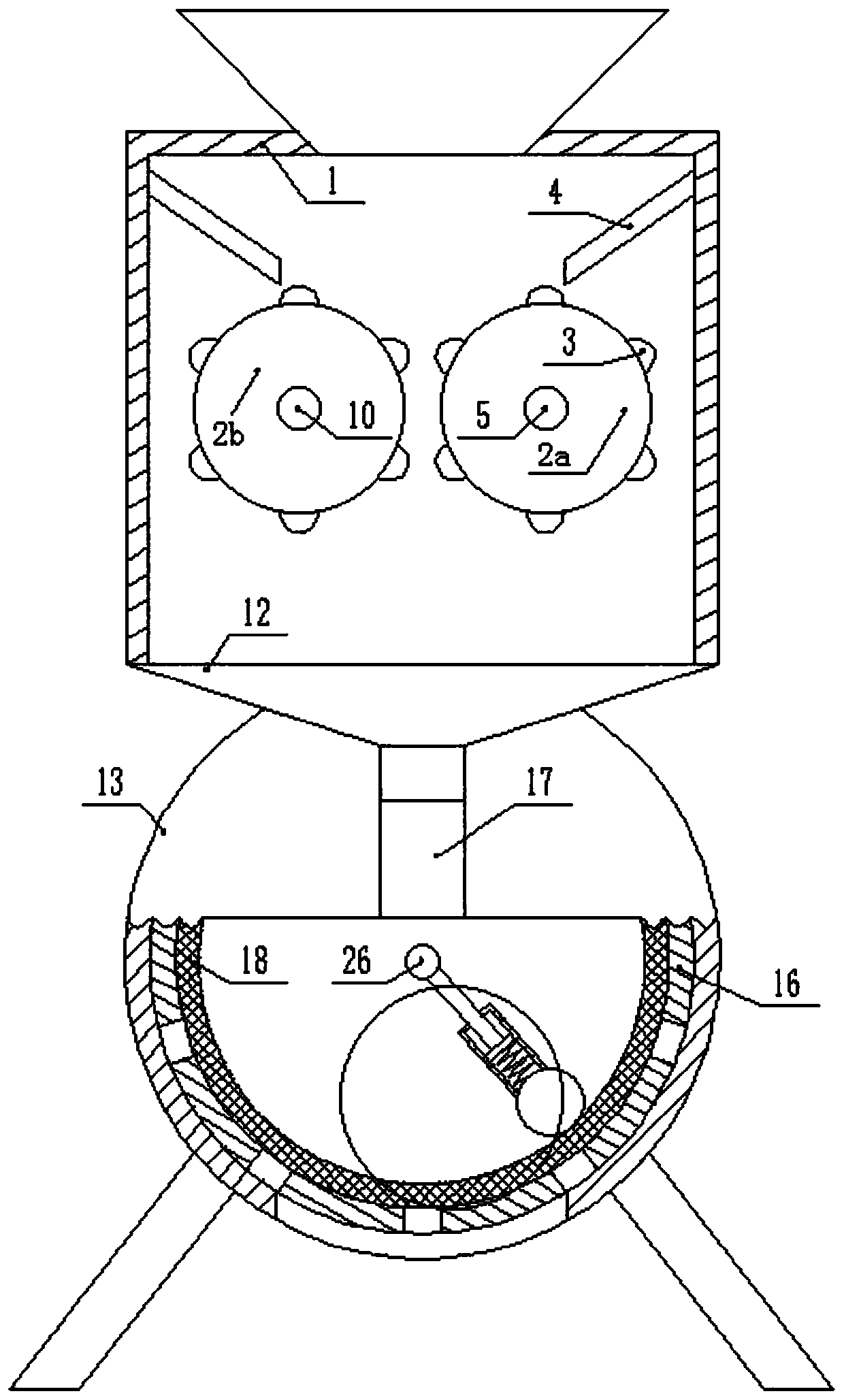

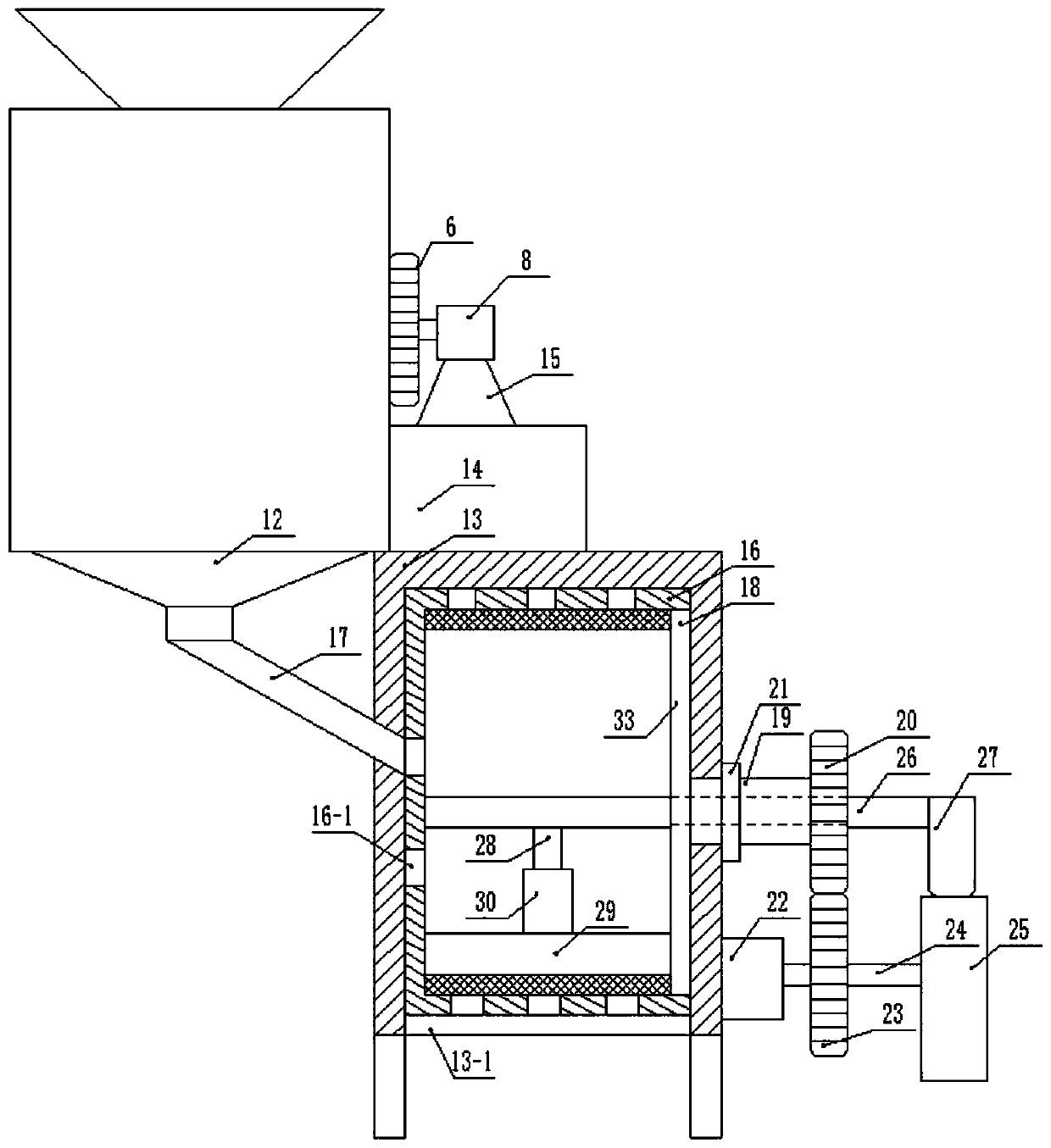

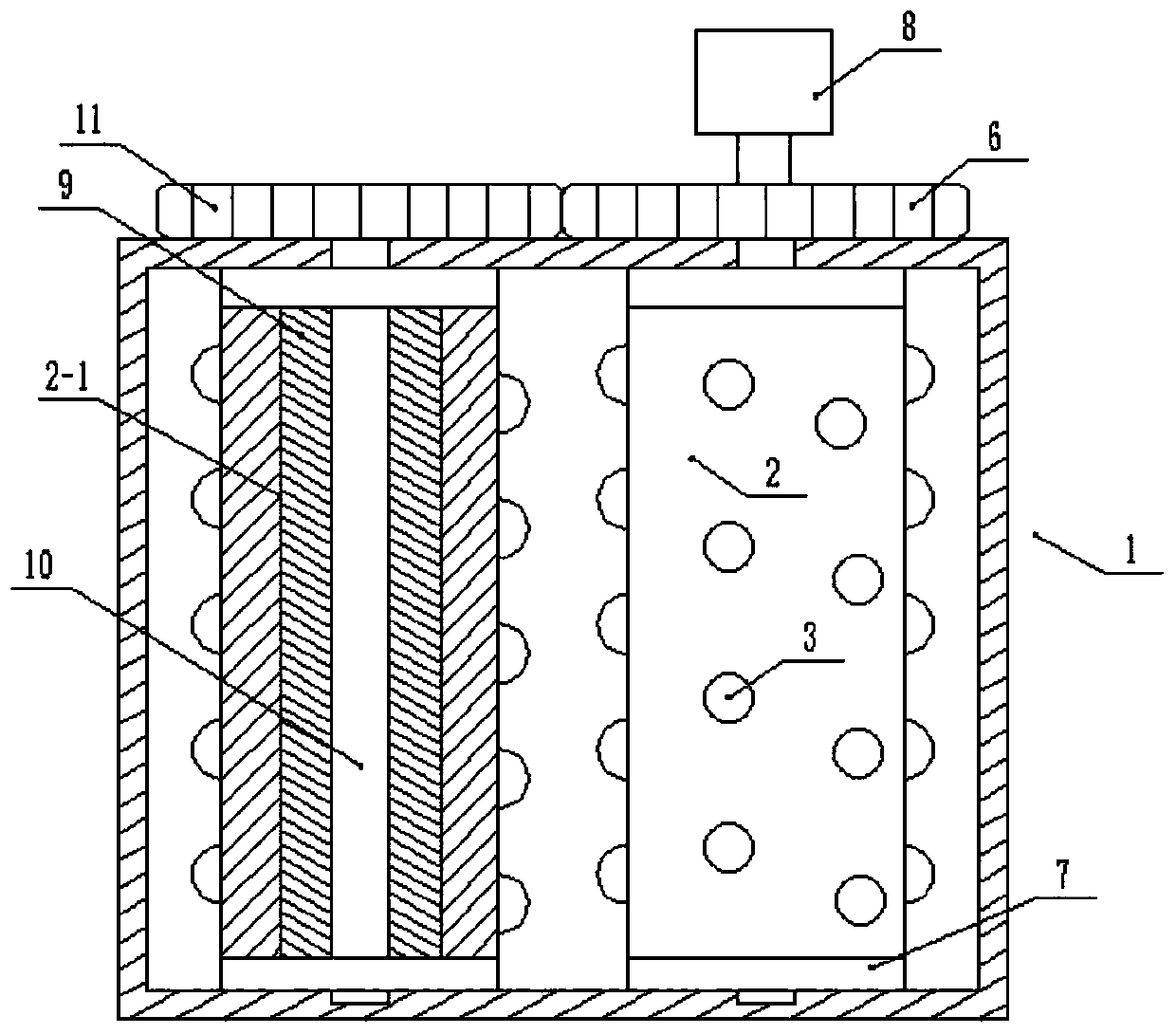

[0025] like Figure 1 to Figure 3 As shown, the soil crushing device of the present invention includes a primary crushing device and a grinding device; the bottom end of the primary crushing device and the secondary crushing device are connected through a funnel 12 and an inclined pipe 17 . The primary crushing device includes a crushing bucket 1 , a first crushing assembly and a second crushing assembly; the first crushing assembly includes a first crushing roller 2 a , a first motor 8 , a first gear 6 , and a first rotating shaft 5 .

[0026] The top of the crushing barrel 1 is provided with a feed hopper. There are crushing rollers 2 arranged symmetrically in the crushing barrel 1, and baffles 7 are attached to the two ends of the first crushing roller 2a and the second crushing roller 2b; the surfaces of the first crushing roller and the second crushing roller are fixedly connected with a plurality of bumps 3 . Two inclined plates 4 are symmetrically and fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com