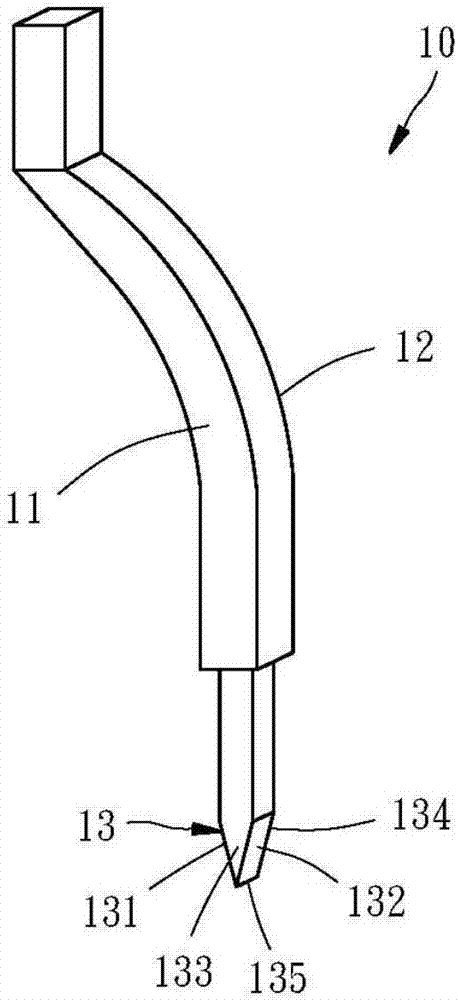

Microelectromechanical probe, method of manufacturing the same and probe set structure

A manufacturing method and micro-electromechanical technology, applied in the direction of manufacturing micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of not sharp enough shape, accelerated probe wear, probe life, poor image recognition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0047] The applicant first explains here that in the embodiments and drawings to be described below, the same reference numerals denote the same or similar elements or structural features.

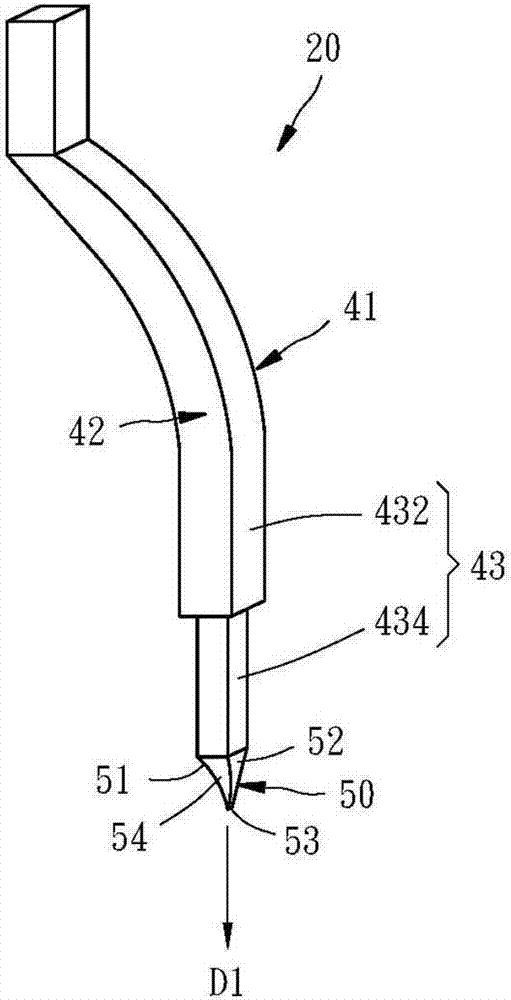

[0048] see figure 2 , the MEMS probe 20 provided by a first preferred embodiment of the present invention is similar to figure 1 The shown buckling probe 10 is conventionally manufactured through the micro-electro-mechanical process, but the design of the tip part is different. The manufacturing method of the micro-electro-mechanical probe 20 will be described below, and the structure of the micro-electro-mechanical probe 20 will also be described. Structure. The manufacturing method of MEMS probe 20 comprises the following steps:

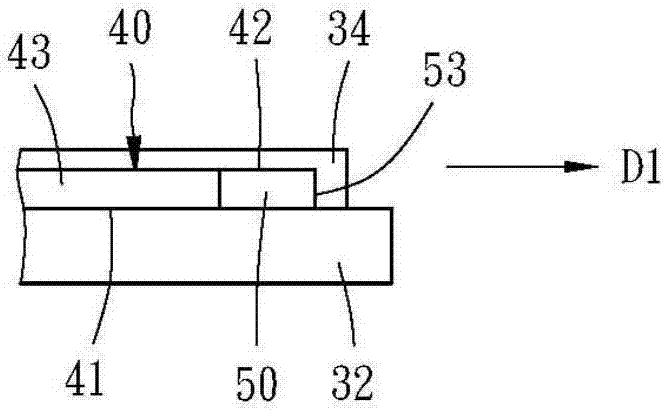

[0049] a) if image 3 As shown, a needle body 40 (as figure 1 As shown in the probe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com