Reinforced foaming floor, and extrusion die and equipment set for preparation of reinforced foaming floor

A technology for extruding molds and floors, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problem of the difficulty in maintaining the strength of PVC foam composite floors, the difficulty in meeting the use requirements of the floor, and the flexural modulus of elasticity. Attenuation and other issues, to achieve the effect of saving material cost and time cost, stable product performance, and reduced defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

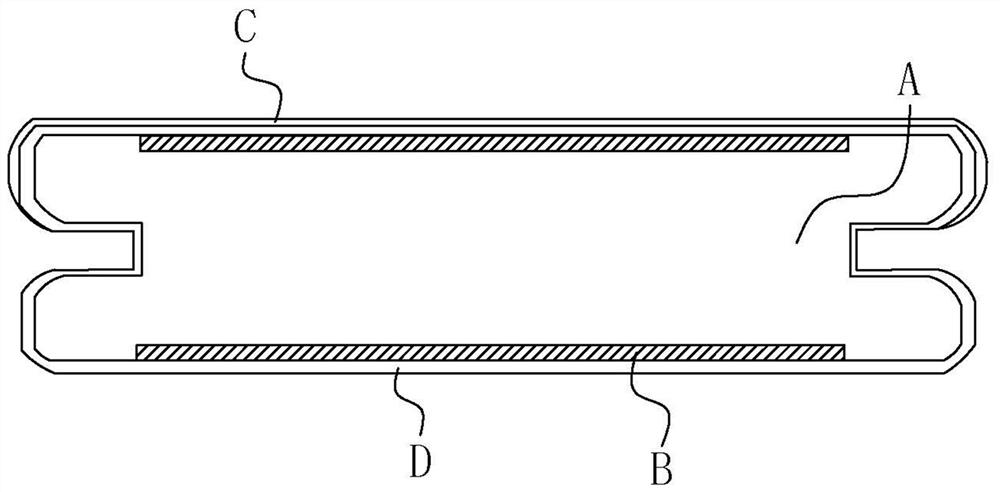

[0060] refer to figure 1 , Enhanced Foam Flooring , the main body is a foam core A made of PVC foam material, two reinforcements B are respectively arranged on the upper and lower surfaces of the foam core A, and the outer periphery of the foam core A is covered with a cylindrical stopper D, the upper surface of the floor is provided with a protective layer C;

[0061] In this embodiment, the reinforcement B is a glass fiber impregnated tape formed by impregnating ABS engineering plastics with glass fibers, the protective layer C is a layer formed of ASA plastic material, and the limiting part D is made of PVC material;

[0062] In the reinforced foam floor described in this embodiment, the vertical section of the foam core A is controlled by the mold to be a rectangle with a length of 140 mm and a width of 24 mm, and its area is 0.336 square decimeters. The maximum number of empty holes whose maximum distance between two points is greater than 0.5 mm is 4, and the number o...

Embodiment 2

[0076] refer to figure 1 , Enhanced Foam Flooring , the technical features are basically the same as those in Embodiment 1. For the convenience of comparison, the exterior specifications of the floor in this embodiment are the same as the floor described in Embodiment 1. The difference is that in the reinforced foam floor described in this embodiment, multiple On the vertical section, the number of empty holes whose maximum distance between any two points is greater than 0.5mm is at most 3, and on most vertical sections, the number of empty holes is 1 or 0.

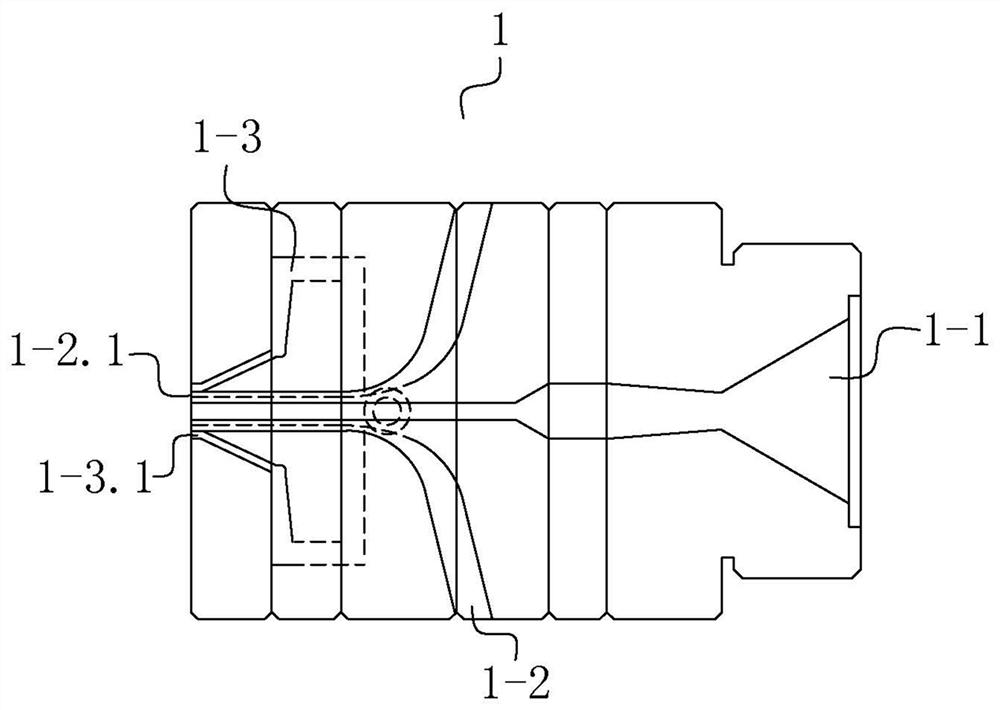

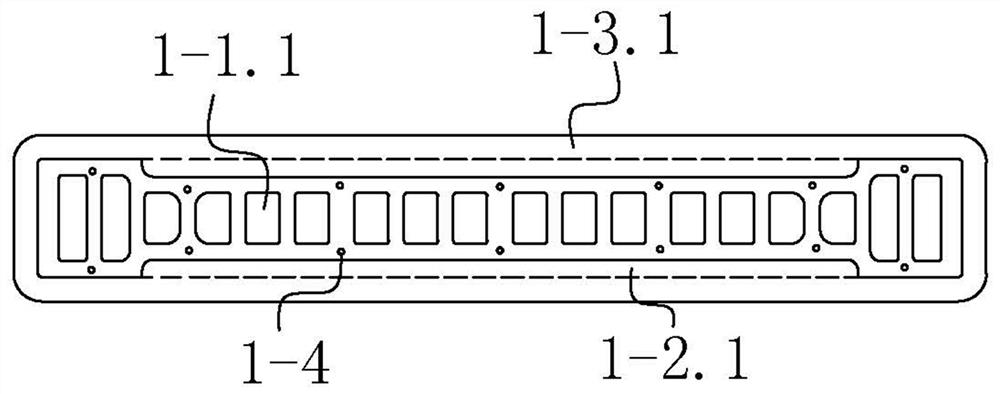

[0077] refer to Figure 2~Figure 5 , for the preparation of the above-mentioned enhanced foam floor extrusion die , technical feature is basically the same as embodiment 1, the difference is:

[0078] The separated flow channel includes a guide extrusion section 1-1.2 in which the flow channel gradually expands in the extrusion direction of the core material. The end point of the expansion of the guide extrusion sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com