Atomizing nozzle and hand-hold atomization gas quenching device with atomizing nozzle

A technology of atomizing nozzles and nozzle bodies, which is applied in the direction of quenching devices, quenching agents, heat treatment equipment, etc., and can solve the problems of waste of resources, large occupation of land, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

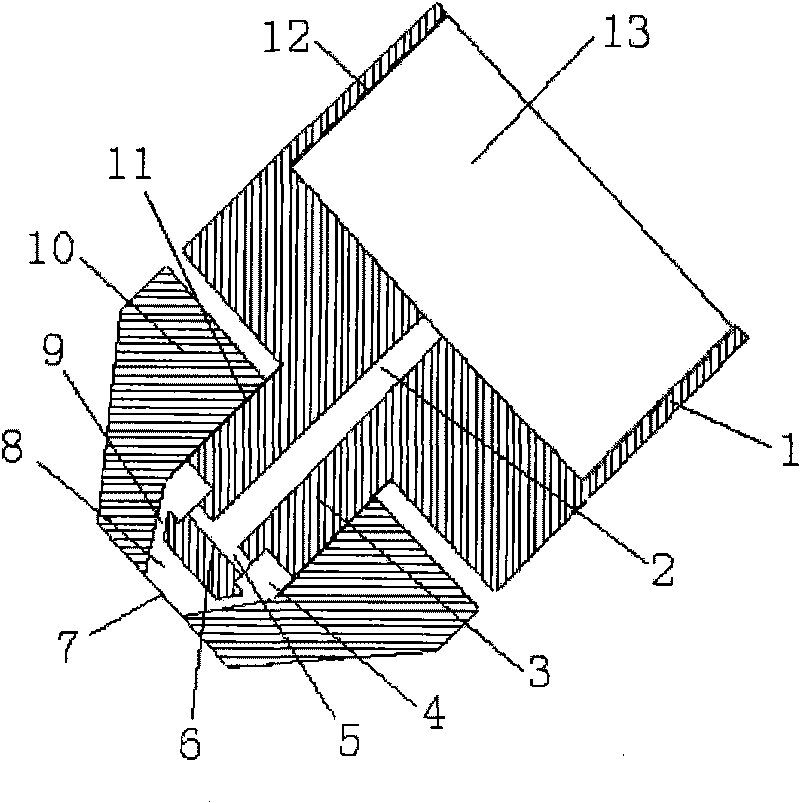

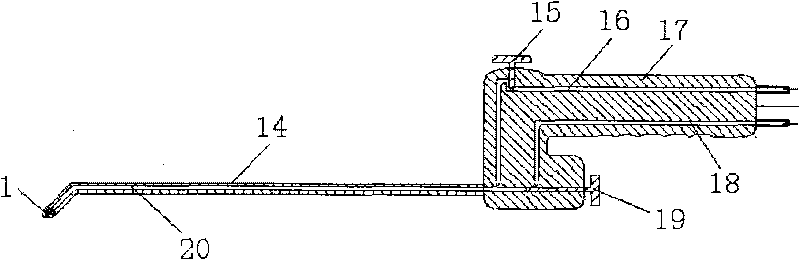

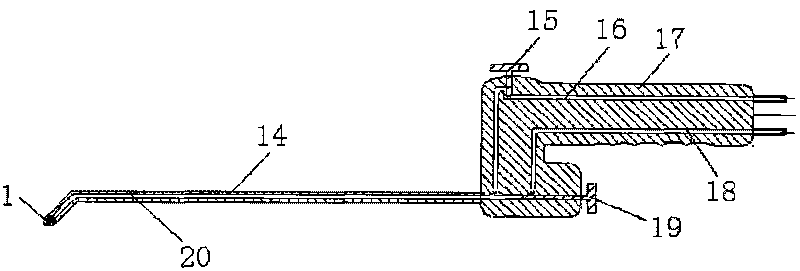

[0016] The atomizing nozzle provided by the present invention includes a nozzle body 1 with a channel, and a rotating head 10 with a cavity and a spout 7 on the nozzle body 1 is provided with it, wherein the cavity inlet on the rotating head 10 The section is set as a columnar cavity 11, the outlet section is set as a conical cavity 8, the conical cavity 8 communicates with the spout 7, the outlet end of the nozzle body 1 is set as a columnar body 3 that is matched with the rotating head 10, and the columnar body 3 passes through the opening of its outer wall. The screw thread is connected with the inner wall thread of the cylindrical cavity 11 of the rotating head 10. The axial passage 2 is arranged in the cylindrical body 3, and the radial passage 5 at the end of the cylindrical body communicated with the axial passage 2, and the outlet end of the cylindrical body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com