Foundry waste sand regeneration and shock absorption device

A technology of casting waste sand and shock absorption device, which is applied to casting molding equipment, manufacturing tools, machinery for cleaning/processing of casting materials, etc. Vibration, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

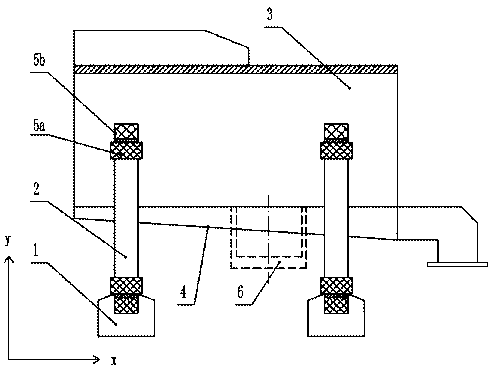

[0014] Such as figure 1 Shown: Foundry waste sand regeneration shock absorption device, including base 1, base 1 is provided with a plurality of support columns 2, support columns 2 are connected to filter screen 3, and below the filter screen 3 is also provided with a conveying plate arranged obliquely 4. The output end of the conveying plate 4 is connected to the hoarding tank of foundry waste sand; the support column 2 is overlapped with a damping spring 5a along the X-axis direction, a damping spring 5b along the Y-axis direction, and a filter screen The bottom of 3 is provided with a vibration source in the Z-axis direction, the vibration source is the eccentric wheel 6, and the eccentric wheel 6 is connected with the motor.

[0015] In this embodiment, the vibration source on the Z-axis direction is turned on to cause the filter screen 3 to vibrate two-dimensionally. Since the support column 2 is connected to the filter screen 3 and the support column 2 is overlapped wit...

Embodiment 2

[0018] Foundry waste sand regeneration and shock absorbing device includes a base 1, a plurality of support columns 2 are arranged on the base 1, the support columns 2 are connected to a filter screen 3, and a conveying plate 4 arranged obliquely is arranged below the filter screen 3 to transport The output end of the plate 4 is connected to the hoarding tank of foundry waste sand; both ends of the support column 2 are overlapped with a damping spring 5a along the X-axis direction, a damping spring 5b along the Y-axis direction, and a filter screen The bottom of 3 is provided with a vibration source in the Z-axis direction, the vibration source is the eccentric wheel 6, and the eccentric wheel 6 is connected with the motor.

[0019] In this embodiment, the vibration source on the Z-axis direction is turned on to cause the filter screen 3 to vibrate two-dimensionally. Since the support column 2 is connected to the filter screen 3 and the support column 2 is overlapped with a dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com