A preparation method of electrothermal alloy and the prepared electrothermal alloy material

An electrothermal alloy and intermediate alloy technology, applied in the field of materials, can solve the problems such as the inability to effectively control the number of defects, the difficulty of alloy resistivity, etc., and achieve great economic significance and market value, and the effect of increasing the resistivity and increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

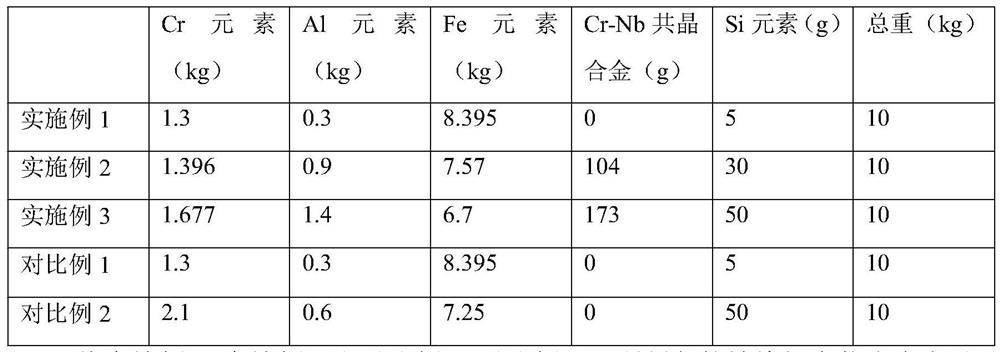

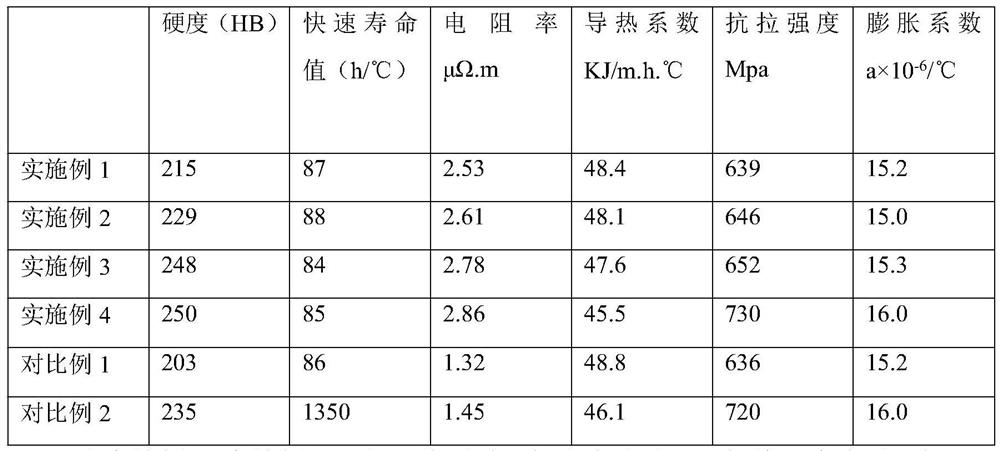

[0049] The preparation method of the electrothermal alloy in this embodiment uses the composition of 0Cr21Al6Nb alloy as the basis for composition control, and the ratio of the addition of alloy elements is shown in Table 1. The specific operation method of smelting is as follows:

[0050] S1. Cr-Nb eutectic alloy is smelted in advance for use; when Cr-Nb eutectic alloy is smelted in advance, the melting temperature is 2510-2520°C, and the holding time is 1.5min, that is, Cr and Nb are smelted into a melt;

[0051] S2. Determine the total mass of the electrothermal alloy for each smelting, and calculate the mass of each alloy element; change the added Nb metal element to add Cr-Nb eutectic alloy, and calculate the mass of Nb required for smelting, use Cr-Nb The quality of Nb contained in the eutectic alloy is replaced, and the quality of the Cr element in the added Cr-Nb eutectic alloy is calculated, and the quality of the missing Cr element is calculated; then the balance met...

Embodiment 2

[0060] The preparation method of the electrothermal alloy in this embodiment uses the composition of 0Cr21Al6Nb alloy as the basis for composition control, and the ratio of the addition of alloy elements is shown in Table 1. Its concrete smelting operation method is basically the same as embodiment 1, and its difference is:

[0061] S1. When melting the Cr-Nb eutectic alloy in advance, the melting temperature is 2500-2510 ° C, and the holding time is 3 minutes, that is, Cr and Nb are smelted into a melt. The steps of S2 and S3 are the same as those in Example 1 to make an iron-chromium-aluminum electrothermal alloy ingot. Then roll it into a thin strip, and perform the first annealing (recrystallization annealing). The annealing options include roller bottom annealing or pit furnace annealing to reduce the hardness of the alloy and facilitate subsequent processing. The recrystallization annealing temperature is 820-850° C., and the holding time is 10 minutes.

[0062] Subseq...

Embodiment 3

[0064] The preparation method of the electrothermal alloy in this embodiment uses the composition of 0Cr21Al6Nb alloy as the basis for composition control, and the ratio of the addition of alloy elements is shown in Table 1. The specific smelting operation method is basically the same as that of Example 1, the difference is: S3. When smelting the electric heating alloy, put the metal aluminum, industrial pure iron, Cr-Nb master alloy, and the balance metal Cr into the intermediate frequency vacuum in sequence In the induction melting furnace, evenly disperse the silicon powder powder into the middle and upper layers, so that the silicon powder powder is dispersed in the electrothermal alloy matrix; the melting temperature is set to 1950-2000 ℃ in gradient, and the holding time is 2-4min, 1770-1800 ℃ Heat preservation for 3-5 minutes, heat preservation at 1600°C-1630°C for 1-3 minutes, after repeated melting (can be adjusted according to the specific process, 3 to 5 times in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com