Method for improving production efficiency of Q345B hot rolled narrow strip steel

A technology of production efficiency and narrow strip steel, which is applied in the field of steel rolling, can solve the problems of large temperature loss, large amount of alloy added, and inability to power on to raise temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1 is the production route of Q345B hot-rolled narrow-strip steel that adopts high Mn and adds a small amount of V microalloying. Embodiment 2 and 3 are the production of Q345B hot-rolled narrow-strip steel that adopts Mn reduction and adds Nb to carry out Nb-V composite microalloying. route.

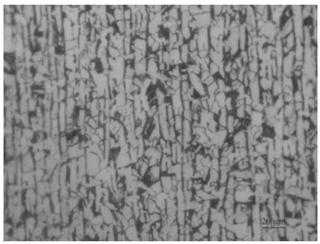

[0087] Embodiment 1 (comparative example)

[0088] The Q345B hot-rolled narrow steel strip with high Mn and a small amount of V microalloying is used, and its composition range is shown in Table 2:

[0089] Table 2 Component Range

[0090]

[0091] Hot metal pretreatment - top and bottom double blowing converter smelting - strip billet continuous casting - hot rolling.

[0092] The molten iron pretreatment operation process is:

[0093] (1) The molten iron adopts the desulfurization method of injecting magnesium particles. The injection amount of magnesium particles is: 0.3kg / t iron, the sulfur content of the molten iron is controlled below 0.020%, and the desulfu...

Embodiment 2

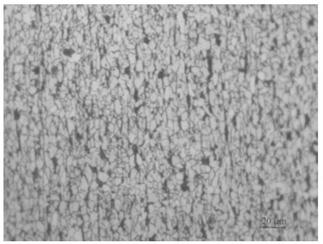

[0129] The invention provides a production method of a hot-rolled narrow steel strip containing NbQ345B, which is used for reducing the addition of alloy material, improving production efficiency and reducing alloy cost.

[0130] Its ingredients range from:

[0131] Table 4 Component Range

[0132]

[0133]

[0134] The molten iron pretreatment operation process is: (1) The molten iron adopts the desulfurization method of injecting magnesium particles, the injection amount of magnesium particles is: 0.5kg / t iron, the sulfur content of the molten iron is controlled below 0.020%, and the desulfurization slag is removed after desulfurization.

[0135] The converter operation process is:

[0136] (1) The converter is smelted with a single slag process, and the basicity of the final slag is controlled at R=3.2, so that the slag can be melted early at the initial stage, the slag can be melted well in the process, and the final slag can be fully melted.

[0137] The single sl...

Embodiment 3

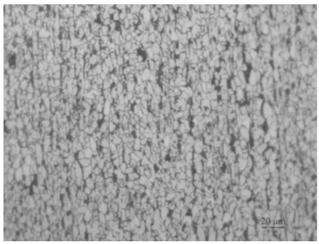

[0171] The invention provides a production method of a hot-rolled narrow steel strip containing NbQ345B, which is used for reducing the addition of alloy material, improving production efficiency and reducing alloy cost.

[0172] Its ingredients range from:

[0173] Table 6 Component Range

[0174]

[0175] The operation process of molten iron pretreatment is as follows: (1) The molten iron adopts the desulfurization method of injecting magnesium particles, the injection amount of magnesium particles is: 0.4kg / t iron, the sulfur content of molten iron is controlled below 0.020%, and the desulfurization residue is removed after desulfurization.

[0176] The converter operation process is:

[0177] (1) The converter is smelted with a single slag process, and the basicity of the final slag is controlled at R=3.1, so as to achieve early slag melting in the initial stage, good slag melting in the process, and thorough final slag melting.

[0178] The single slag method is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com