Method for extracting manganese from electrolytic manganese waste residues or low-quality manganese ore by utilizing mechanochemical method and auxiliary agent thereof

A technology of mechanochemical method and electrolysis of manganese waste residue, which is applied in the field of manganese in low-quality manganese ore, can solve the problems of polluting the environment and wasting resources, and achieve the effects of improving utilization rate, alleviating the environment, developing production, and benefiting comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

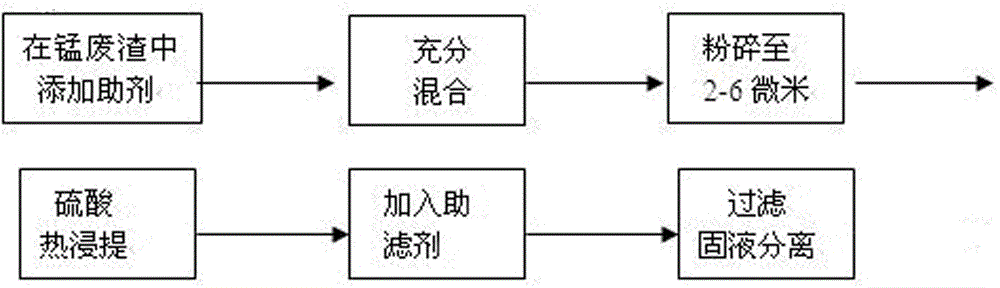

Method used

Image

Examples

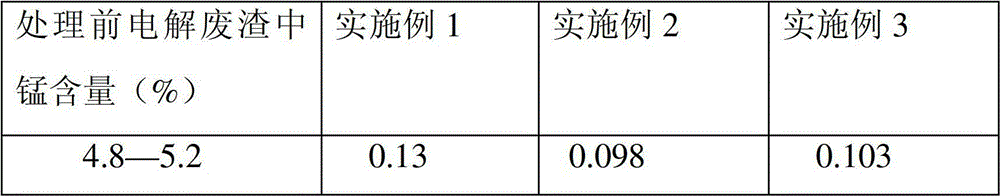

Embodiment 1

[0018] In the electrolytic manganese waste slag, add 6% by weight of the auxiliary agent, the auxiliary agent consists of 0.5 parts of sodium dodecylbenzenesulfonate, 2.0 parts of potassium hydroxide, and 2.0 parts of iron trichloride in parts by weight, fully mixed After homogeneously, pulverize to 6 microns; then use 85wt% sulfuric acid for hot leaching, in which solid powder: liquid sulfuric acid = 1:8 by weight, hot leaching twice at 95°C, and then add the aforementioned filter aid 1.5 parts of iron trichloride, then vacuum filtration makes solid-liquid separation, so that after filtering and separating solids (a filter cake with a thickness of 20mm), (acid leaching solution) is used as an electrolytic solution for electrolytic manganese production.

[0019] Before use, the acid leaching solution can be adjusted according to the needs of the specific electrolysis process, and after the manganese content of the solid is determined, it can be used as waste for comprehensive u...

Embodiment 2

[0022] Add 8% by weight of additives to the electrolytic manganese waste residue. The additives are composed of 0.5 parts of sodium heptadecylbenzenecarboxylate, 2.0 parts of sodium carbonate, and 2.5 parts of aluminum trichloride in parts by weight. Mix well After that, crush them together to 5 microns; then use 90wt% sulfuric acid for hot leaching, in which solid powder: liquid sulfuric acid = 1:6 by weight, hot leaching for 3 times at 98°C, and then add the aforementioned filter aid three 3.0 parts of aluminum chloride, and then vacuum filtration to separate the solid and liquid, thereby filtering and separating the solid matter (a filter cake with a thickness of 20 mm), as an electrolytic solution for electrolytic manganese production.

[0023] Before use, the acid leaching solution can also be adjusted as needed, and after the manganese content of the solid is determined, it can be used as waste for comprehensive utilization or landfill according to national regulations. ...

Embodiment 3

[0026] In the electrolytic manganese waste slag, add 4% by weight of additives, the additives are composed of 0.5 parts of pull-off powder, 1.5 parts of calcium oxide, and 0.5 parts of polyacrylamide in parts by weight. After fully mixing, they are pulverized together to 3 Micron; then hot extraction with 80wt% sulfuric acid, in which solid powder: liquid sulfuric acid = 1:9 by weight, hot extraction twice at 98°C, combined extracts, and then added the aforementioned filter aid polypropylene 1.5 parts of amide, and then vacuum filtration to separate the solid from the liquid, thereby filtering out the solid (a filter cake with a thickness of 20 mm), and then use it as an electrolytic solution for electrolytic manganese production.

[0027] Before use, the acid leaching solution can also be adjusted as needed, and after the manganese content of the solid is determined, it can be used as waste for comprehensive utilization or landfill according to national regulations.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com