Non-quenched and tempered steel containing Ti and N and applied to automobile engine crankshaft and preparation method

A technology of automobile engine and non-quenched and tempered steel, applied in the direction of crankshaft, etc., can solve the problems of increasing production cost, and achieve the effect of reducing machining cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

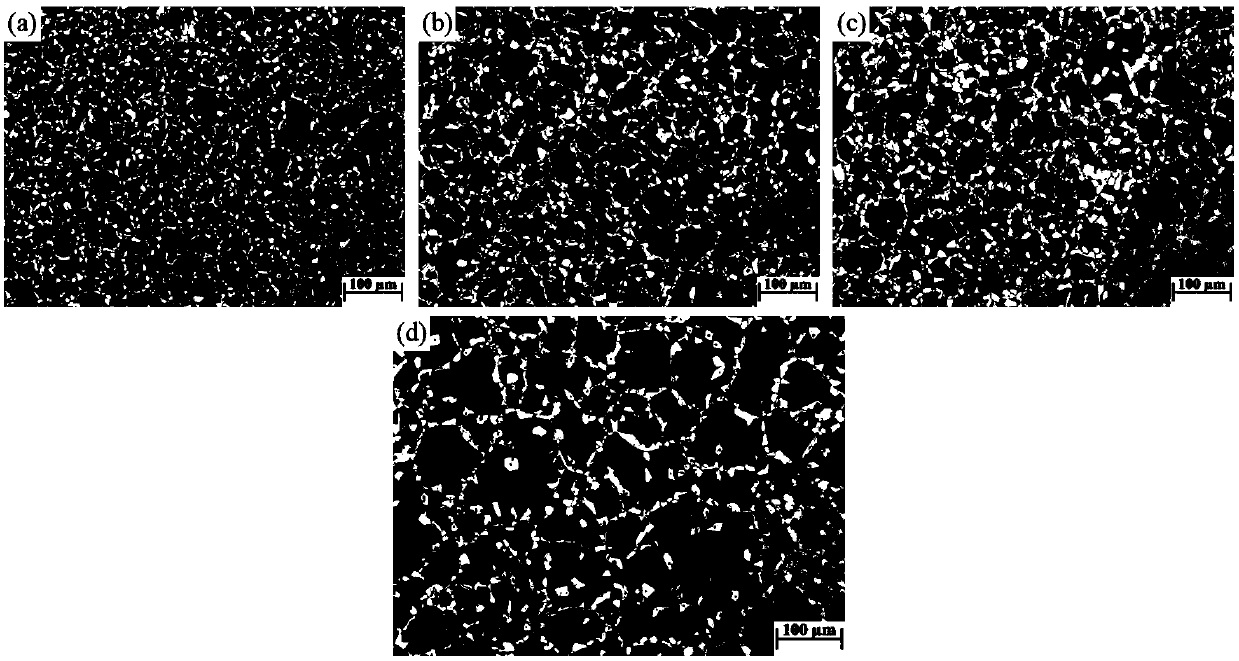

[0024] In Example 4, Ti and N are not added to the chemical composition. The austenite grain size of the rolled product is 6.5-8.0, with a range of 1.5; the structure at the center and 1 / 2 radius is relatively coarse, and the uniformity of the structure is poor. Room temperature impact energy KU of the crankshaft 2 The average value is only 8J, and the cross-section hardness of the output end is too high, ranging from 262 to 286HB.

Embodiment 5

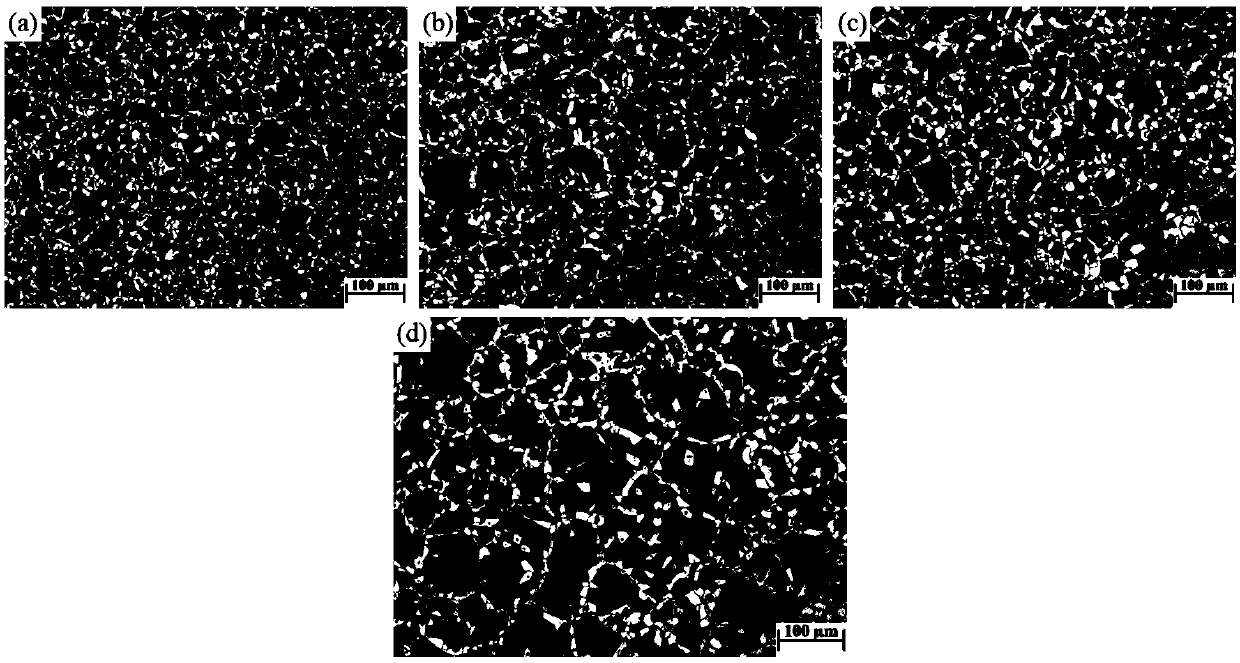

[0025] In Example 5, the Mn and Cr in the chemical composition exceeded the upper limit required by the composition. The austenite grain size of the rolled material is 8.0-8.5, the extreme difference is 0.5, and the structure is fine and uniform. But the room temperature impact energy KU of the crankshaft 2 The average value is only 14J, and the cross-section hardness of the output end is too high, ranging from 261 to 276HB.

[0026] The chemical composition (mass percentage) that the embodiment of table 1 adopts

[0027]

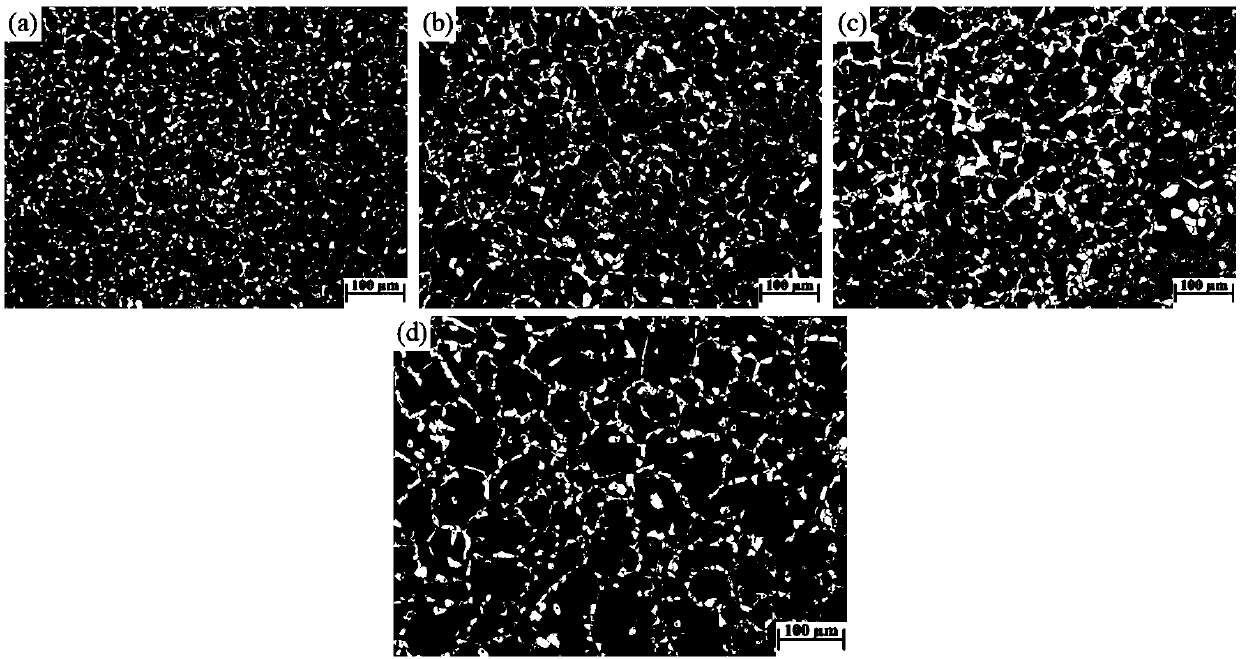

[0028] Table 2 embodiment rolling material organization statistical result

[0029]

[0030] Table 3 embodiment crankshaft performance test result

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy at room temperature | aaaaa | aaaaa |

| Impact energy at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com