Magnesium phosphate cement containing C4AF solid solution and preparation method

A technology of magnesium phosphate cement and solid solution, applied in the field of building materials, can solve the problems of staying, water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

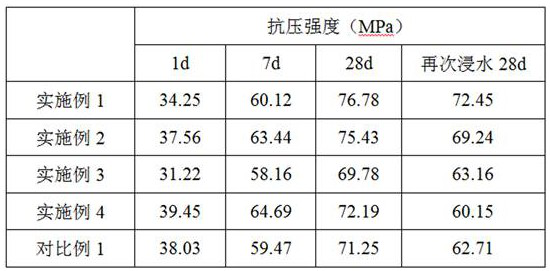

Examples

Embodiment 1

[0034] a C 4 Magnesium phosphate cement of AF solid solution, the main components of which are by weight: C 4 40 parts of AF solid solution, 35 parts of MgO, 20 parts of ammonium dihydrogen phosphate, and 5 parts of borax; the preparation process mainly includes the following steps:

[0035] (1) C 4 AF solid solution precursor preparation, according to C 4 The stoichiometry of AF solid solution Weigh the calcareous components, aluminum-containing components and iron-containing minerals and mix and homogenize;

[0036] (2) Take the homogenized precursor in step (1), calcinate it at 1000~1500°C for 20min~3h, take it out and let it cool naturally.

[0037] (3) Take the sintered material after cooling in step (2), and perform grinding treatment, and the fineness is controlled below 75 μm.

[0038] (4) C will be obtained 4 AF solid solution was prepared with commercially available dead-burned MgO, phosphate, and borax according to the composition ratio of 40:35:20:5 to obtain ...

Embodiment 2

[0040] a C 4 Magnesium phosphate cement of AF solid solution, its main components are by weight: 35 parts C 4 AF solid solution, 40 parts of MgO, 17 parts of ammonium dihydrogen phosphate, 8 parts of borax; the preparation process mainly includes the following steps:

[0041] (1) C 4 Preparation of AF solid solution and MgO mixture precursor, according to C 4 For the ratio range of AF solid solution to magnesium oxide, weigh calcium and magnesium components, aluminum-containing components and iron-containing minerals and mix and homogenize.

[0042] (2) Take the homogenized precursor in step (1), calcinate it at 1000~1500°C for 20min~3h, take it out and cool it naturally to get C 4 AF solid solution-MgO mixture.

[0043] (3) Take the sintered product after rapid cooling in step (2), and perform grinding treatment, and the fineness is controlled below 75 μm.

[0044] (4) put C 4 The AF solid solution-MgO mixture was prepared with phosphate and borax according to the composi...

Embodiment 3

[0046] a C 4 The magnesium phosphate cement of AF solid solution, its main component is by weight: 42 parts C 4 AF solid solution, 30 parts of MgO, 20 parts of ammonium dihydrogen phosphate, 5 parts of borax, of which 3 parts of boron oxide are in synergy C 4 The AF solid solution-MgO mixture is introduced during the firing process, mainly including the following steps:

[0047] (1) C 4 Preparation of AF solid solution-MgO precursor according to C 4 AF:MgO:B 2 o 3 The ratio is 56:40:4, weigh dolomite, aluminum ash, iron oxide and boron oxide and mix and homogenize.

[0048] (2) Take the homogenized precursor in step (1), calcinate it at 1000~1500°C for 20min~3h, take it out and cool it naturally to get C 4 AF solid solution-MgO mixture.

[0049] (3) Take the sintered product after rapid cooling in step (2), and perform grinding treatment, and the fineness is controlled below 75 μm.

[0050] (4) put C 4 The AF solid solution-MgO mixture is prepared with phosphate and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com