A kind of graphene-reinforced magnesium-based composite material and preparation method thereof

A composite material, graphene technology, applied in metal extrusion control equipment, manufacturing tools, metal processing equipment and other directions, can solve problems such as poor interface bonding, easy to produce agglomeration, and difficulty in obtaining high volume fraction of graphene, and achieve improved Content, high strength, the effect of ensuring the safety of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

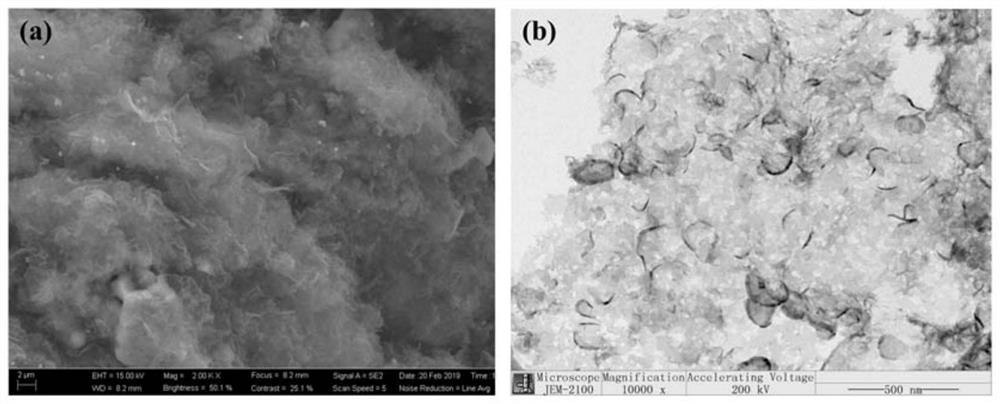

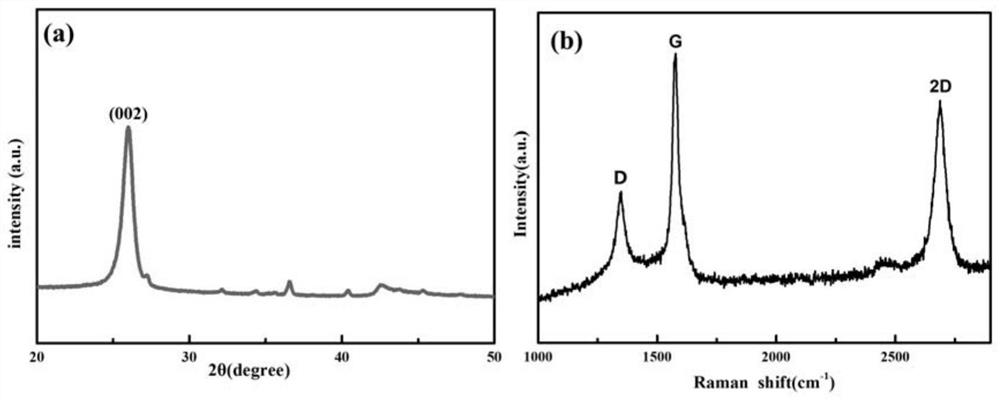

[0031]The present invention provides a kind of preparation method of graphene-reinforced magnesium-based composite material in the first aspect, described method comprises the steps:

[0032] (1) The magnesium matrix is heated and melted in a crucible to obtain a magnesium matrix melt; air or a mixed gas formed by mixing oxygen and a rare gas is introduced at the top of the crucible. In the present invention, for example, an aerator is used to A certain flow of air or a mixed gas formed by mixing oxygen and rare gas (such as argon) is introduced into the top of the crucible, so that the top of the crucible is in direct contact with the flowing air or the flowing mixed gas, so The volume percentage of oxygen in the mixed gas is 10% to 30% (such as 10%, 15%, 20%, 25% or 30%). The mixed gas is, for example, mixed with oxygen and argon, and oxygen and argon The volume ratio of gas is 1:4; the magnesium matrix is one or more of magnesium-zinc alloy, magnesium-calcium alloy, mag...

Embodiment 1

[0056] The preparation method of the graphene-reinforced magnesium-based composite material of the present embodiment is as follows:

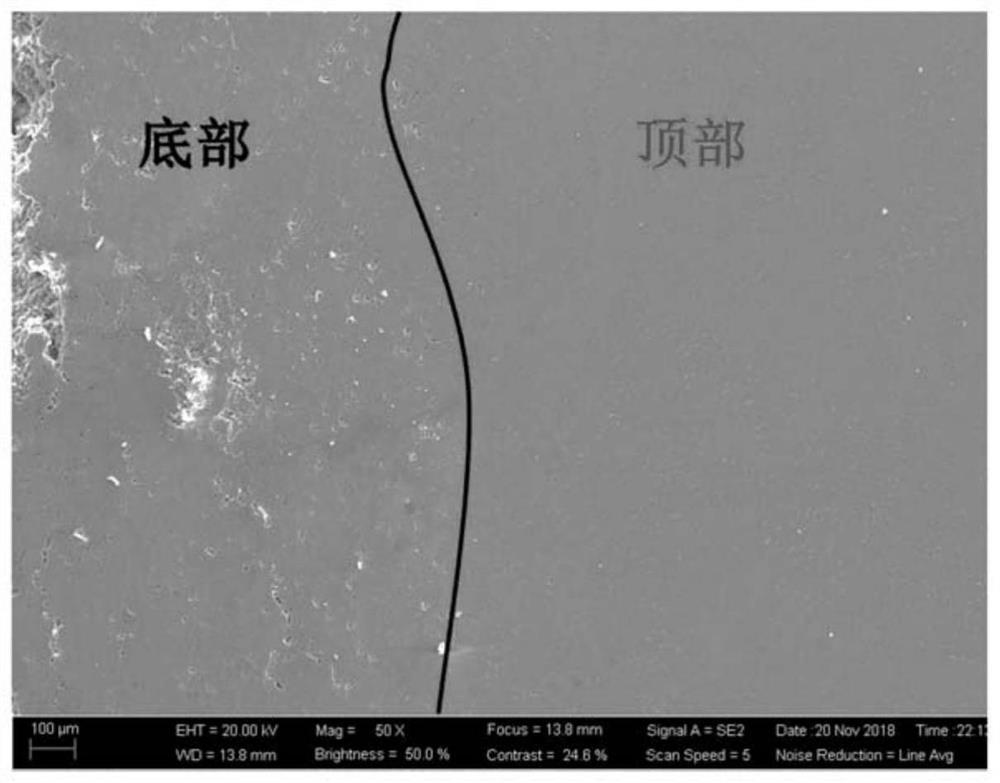

[0057] 1. Heat and melt 700g of Mg-6Zn alloy (magnesium matrix) in a crucible at 720°C to obtain a magnesium matrix melt; wherein, the melted volume of the magnesium matrix accounts for 3 / 5 of the volume of the crucible, and air is introduced at the top of the crucible , so that the top of the crucible is in direct contact with the flowing air;

[0058] 2. Adjust the temperature of the magnesium matrix melt to 680°C, and continuously inject CO gas into the magnesium matrix melt at a flow rate of 2L / min for 40 minutes to carry out gas-liquid in-situ reaction, accompanied by mechanical stirring, and the stirring speed is 600r / min. min, to obtain a graphene-reinforced alloy melt with a graphene content ratio of 0.6wt.%. While the gas-liquid in-situ reaction occurs between the CO gas and the magnesium matrix melt, the temperature at the top of the ...

Embodiment 2

[0064] The preparation method of the graphene-reinforced magnesium-based composite material of the present embodiment is as follows:

[0065] 1. Heat and melt 700g Mg-4Zn-0.5Ca alloy in a crucible at 720°C to obtain a magnesium matrix melt; wherein, the melted volume of the magnesium matrix accounts for 1 / 2 of the volume of the crucible, and air is introduced at the top of the crucible, Keep the top of the crucible in direct contact with the flowing air;

[0066] 2. Adjust the temperature of the magnesium matrix melt to 680°C, and continuously inject CO gas into the magnesium matrix melt at a flow rate of 2L / min for 40 minutes to carry out gas-liquid in-situ reaction, accompanied by mechanical stirring, and the stirring speed is 600r / min. min, to obtain a graphene-reinforced alloy melt with a graphene content ratio of 0.6wt.%. While the gas-liquid in-situ reaction occurs between the CO gas and the magnesium matrix melt, the temperature at the top of the crucible is guaranteed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com