Method for improving flotation recovery rate of copper and nickel and reducing content of magnesium oxide in concentrates of copper-nickel sulfide ores

A technology for copper-nickel sulfide ore and flotation recovery rate, which is applied in flotation, solid separation and other directions, can solve the problems of high dosage of regulators and has not yet been studied, and achieves the advantages of reducing content, increasing floatability, and promoting adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The ore sample is an ore sample from the copper-nickel sulfide mining area in Jinchuan, Gansu Province. One or several of xanthate, butyl xanthate, and pentaxanthate are used as collectors, and sodium carbonate is used as a pH regulator for foam flotation. .

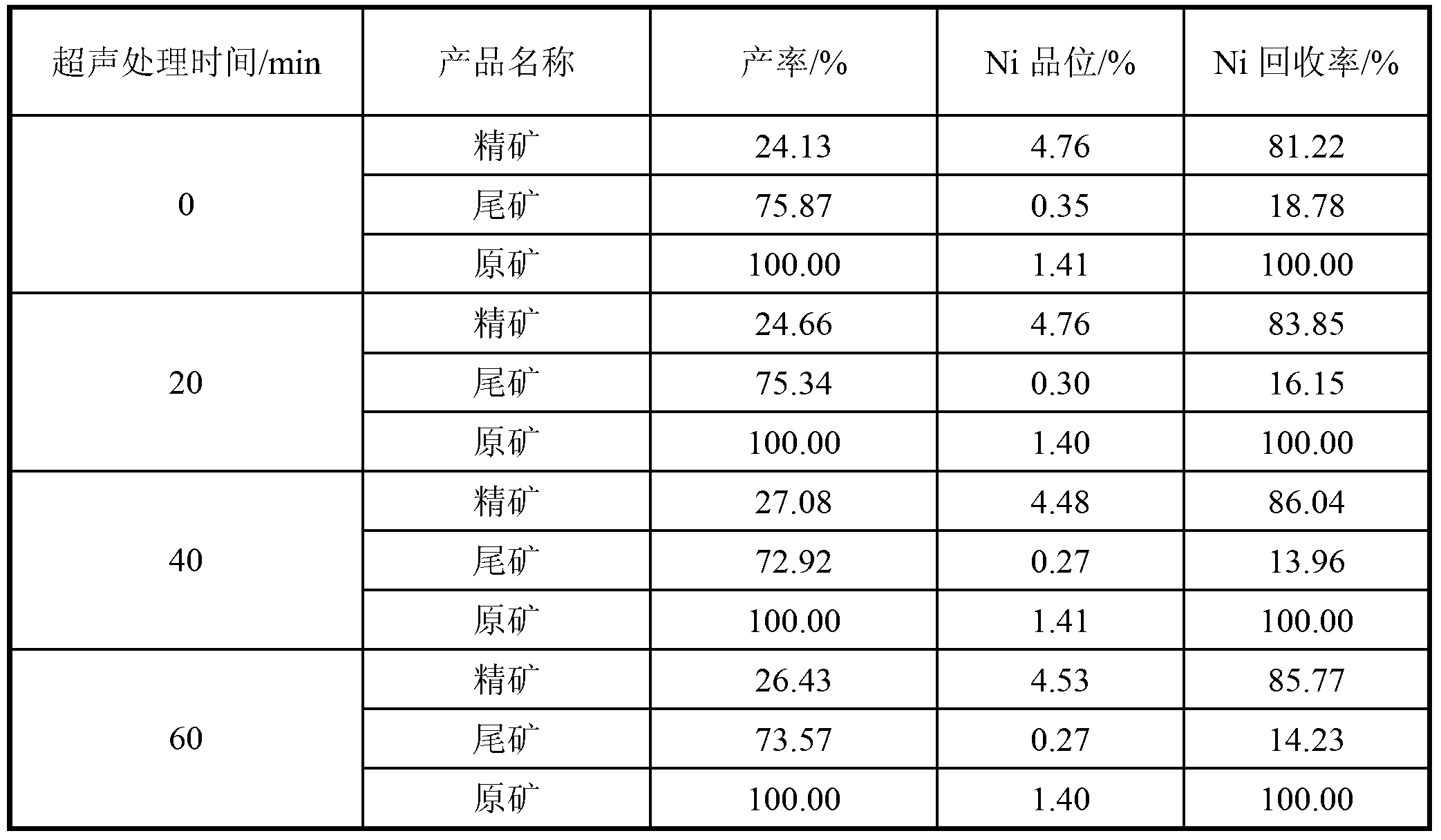

[0016] The process is: grind the ore to -0.074mm, accounting for 65%, add a collector, use ultrasonic treatment for different times, and then conduct a rough separation. See Table 1 for the selection results. It can be seen from the data in Table 1 that by appropriately extending the ultrasonic treatment time, it is helpful for the flotation recovery of serpentine-type copper-nickel sulfide ore, and the recovery rate can be increased by about 4.5%.

[0017] Table 1 Ultrasound time test results

[0018]

Embodiment 2

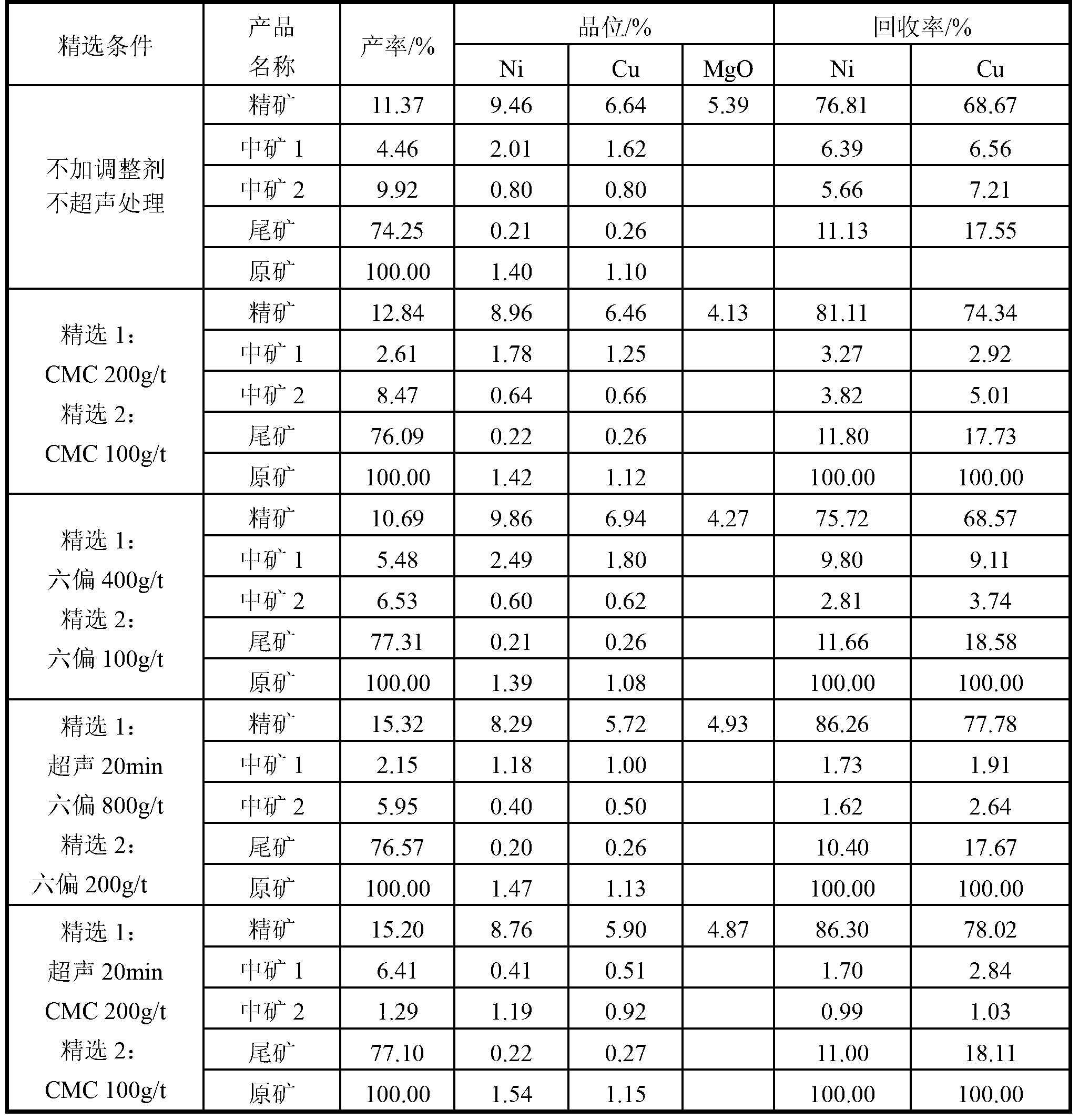

[0020] The ore sample is an ore sample from the copper-nickel sulfide mining area in Jinchuan, Gansu Province. One or several of xanthate, butyl xanthate, and pentaxanthate were used as collectors, sodium carbonate was used as a pH regulator, and sodium hexametaphosphate was used. , Carboxymethyl cellulose (CMC) is used as a regulator for froth flotation.

[0021] The process is as follows: grind the ore to -0.074mm, accounting for 65%, add collectors and carry out dispersion control, and then conduct a rough separation. The coarse concentrate is subjected to ultrasonic dispersion treatment or chemical dispersion treatment, and then two selections are performed. The impact of different decentralized processing methods on selected indicators was compared, and the results are shown in Table 2. As can be seen from the data in Table 2, the use of ultrasonic treatment in the beneficiation process is helpful to the flotation recovery of serpentine-type copper-nickel sulfide ore, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com