A kind of magnesium alloy graphene modifier and its preparation method and application

A magnesium alloy and graphene technology, which is applied in the field of magnesium alloy graphene modifier and its preparation, can solve the problems of poor refinement effect and weakening effect of graphene modifier, achieve high refinement efficiency and improve grain refinement Efficiency, casting performance improved significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a kind of preparation method of magnesium alloy graphene modifier in the first aspect, described method comprises the steps:

[0033] (1) Magnesium (pure magnesium) is heated and melted in a crucible to obtain a magnesium melt; air or a mixed gas formed by mixing oxygen and a rare gas is introduced at the top of the crucible. In the present invention, for example, aeration is used to The device introduces a certain flow of air or a mixed gas formed by mixing oxygen and rare gas (such as argon) into the top of the crucible, so that the top of the crucible is in direct contact with the flowing air or the flowing mixed gas, The volume percentage of oxygen in the mixed gas is 10-25% (such as 10%, 15%, 20% or 25%).

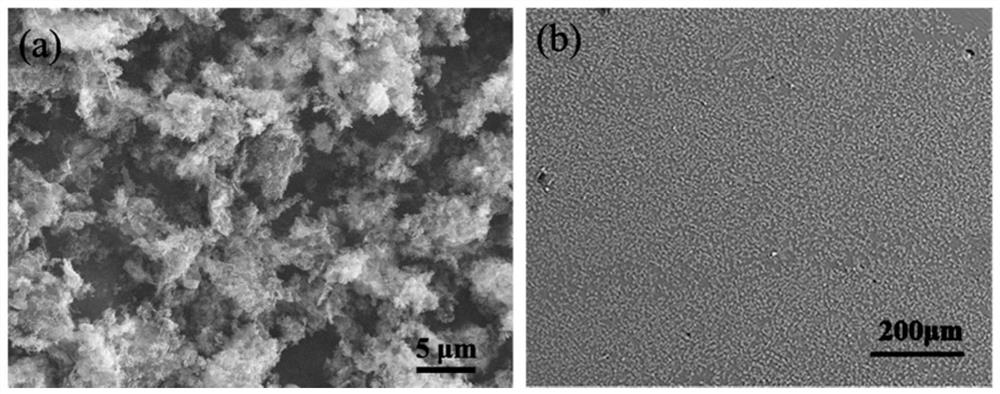

[0034] (2) Continuously feed carbon monoxide (CO) gas into the magnesium melt to carry out magnesia thermal reaction to obtain a composite melt, and the mass percentage of graphene generated in the composite melt is 0.1 to 10% (for...

Embodiment 1

[0056] The preparation method of the magnesium alloy graphene modifier of the present embodiment is as follows:

[0057] 1. Heat and melt 632g of pure magnesium in a crucible at 700°C to obtain a magnesium melt; wherein, the volume of the melted magnesium accounts for 1 / 3 of the volume of the crucible, and air is introduced at the top of the crucible so that the top of the crucible is in contact with the flowing direct contact with air;

[0058] Two, the CO gas with the purity (volume percentage) of 1L / min being 99.9% is continuously fed into the magnesium melt, and the temperature is maintained at 700° C. under the condition of mechanical stirring for 70 min to obtain the magnesium thermal reaction. Composite melt, the graphene that finally generates accounts for 1.5wt.% of composite melt total mass; Wherein, stirring speed is 1500r / min; While CO gas and magnesium melt take place magnesia thermal reaction, ensure that the temperature of crucible top is at Above 300°C, the CO...

Embodiment 2

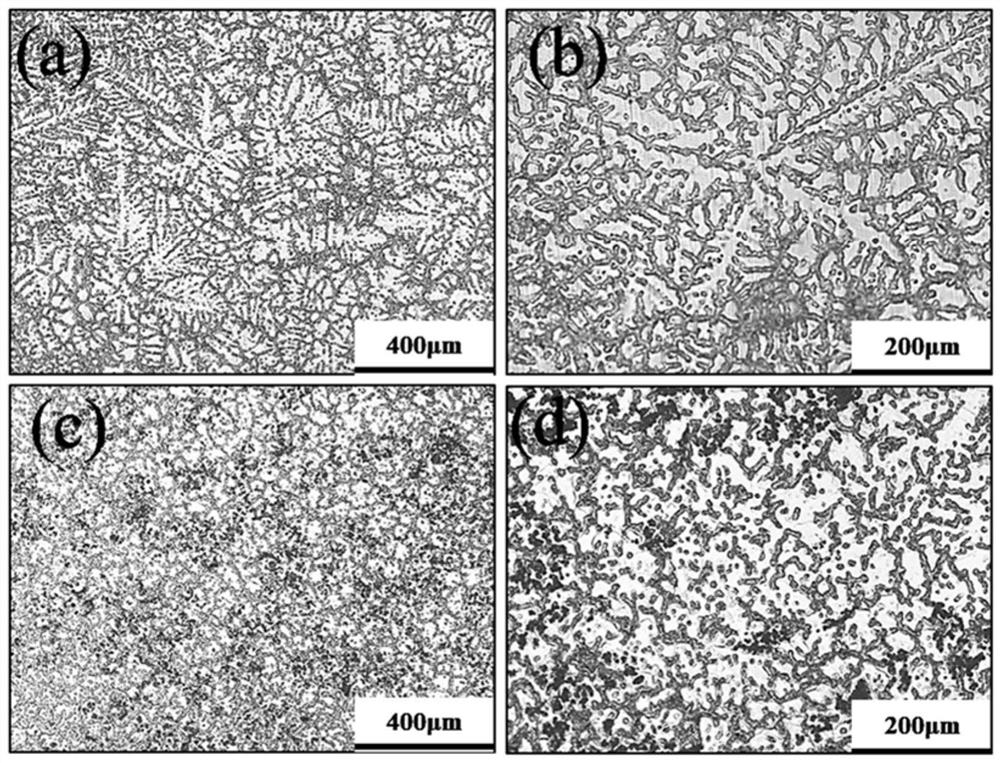

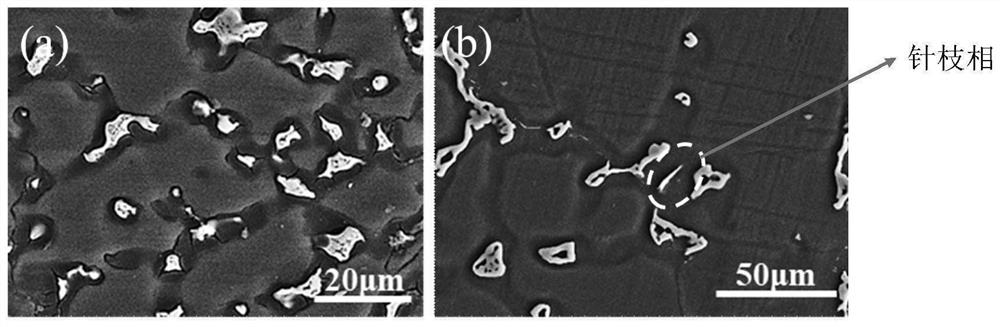

[0062] The preparation method of the fine-grained magnesium alloy of the present embodiment is as follows:

[0063] 1. Heat and melt 632g of pure magnesium in a crucible at 700°C to obtain a magnesium melt; wherein, the volume of the melted magnesium accounts for 1 / 3 of the volume of the crucible, and air is introduced at the top of the crucible so that the top of the crucible is in contact with the flowing direct contact with air;

[0064] Two, the CO gas with the purity (volume percentage) of 1L / min being 99.9% is continuously fed into the magnesium melt, and the temperature is maintained at 700° C. under the condition of mechanical stirring for 70 min to obtain the magnesium thermal reaction. Composite melt, the graphene that finally generates accounts for 1.5wt.% of composite melt total mass; Wherein, stirring speed is 1500r / min; While CO gas and magnesium melt take place magnesia thermal reaction, ensure that the temperature of crucible top is at Above 300°C, the CO gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com