Non-autoclaved aerated concrete prepared by utilizing lithium slag and nickel slag and preparation method of non-autoclaved aerated concrete

An air-entrained concrete, autoclaved-free technology, applied in the field of air-entrained concrete, can solve the problems of lithium slag and nickel slag polluting the environment, high energy consumption, etc., achieve good repair and protection, reduce energy consumption, and use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

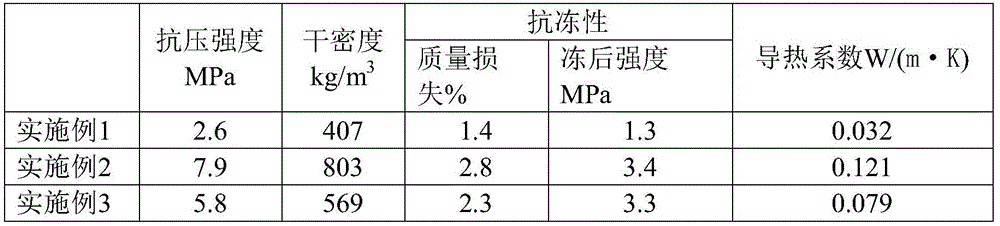

Embodiment 1

[0047] Autoclaved aerated concrete consists of the following components by mass: 80 parts of lithium slag powder, 20 parts of nickel slag powder, 10 parts of 6mol / l sodium hydroxide solution, 30 parts of water glass solution with a modulus of 1, and 0.05 parts of aluminum Powder composition, 0.02 parts of silicone amide.

[0048] The preparation of autoclaved air-entrained concrete includes the following steps:

[0049] 1) Measure lithium slag powder and nickel slag powder in proportion and dry mix for 10 minutes until uniform;

[0050] 2) adding sodium hydroxide solution and water glass solution to lithium slag powder and nickel slag mixed powder, controlling the liquid / solid ratio of sodium hydroxide solution and water glass solution to lithium slag and nickel slag mixed powder to 0.40;

[0051] 3) Add aluminum powder and silicone amide into the slurry in step 2) to foam, and stir for 3 minutes;

[0052] 4) Pour the slurry in step 3) into the mold, and cure at 60°C for 6 h...

Embodiment 2

[0055] Autoclaved aerated concrete consists of the following components by mass: 40 parts of lithium slag powder, 60 parts of nickel slag powder, 13 parts of 10mol / l sodium hydroxide solution, 12 parts of water glass solution with a modulus of 2, and 0.005 parts of aluminum powder , 0.005 parts of silicone amide composition.

[0056] The preparation of autoclaved air-entrained concrete includes the following steps:

[0057] 1) Measure lithium slag powder and nickel slag powder in proportion and dry mix them for 5 minutes until uniform;

[0058] 2) adding sodium hydroxide solution and water glass solution to lithium slag powder and nickel slag mixed powder, controlling the liquid / solid ratio of sodium hydroxide solution and water glass solution to lithium slag and nickel slag mixed powder to 0.25;

[0059] 3) Add aluminum powder and silicone amide into the slurry in step 2) to foam, and stir for 1 minute;

[0060] 4) Pour the slurry in step 3) into the mold, and cure at 80°C ...

Embodiment 3

[0063] Autoclaved aerated concrete is composed of the following components by mass: 60 parts of lithium slag powder, 40 parts of nickel slag powder, 6 parts of 8mol / l sodium hydroxide solution, 24 parts of water glass solution with a modulus of 2, and 0.35 parts of aluminum powder Composition, 0.1 part of silicone amide.

[0064] The preparation of autoclaved air-entrained concrete includes the following steps:

[0065] 1) Measure lithium slag powder and nickel slag powder in proportion and dry mix them for 6 minutes until uniform;

[0066] 2) adding sodium hydroxide solution and water glass solution to lithium slag powder and nickel slag mixed powder, controlling the liquid / solid ratio of sodium hydroxide solution and water glass solution to lithium slag and nickel slag mixed powder to 0.3;

[0067] 3) Add aluminum powder and silicone amide into the slurry in step 2) to foam, and stir for 2 minutes;

[0068] 4) Pour the slurry in step 3) into the mold, and cure at 80°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com