Potassium leach-out exploitation method from mamanite ore

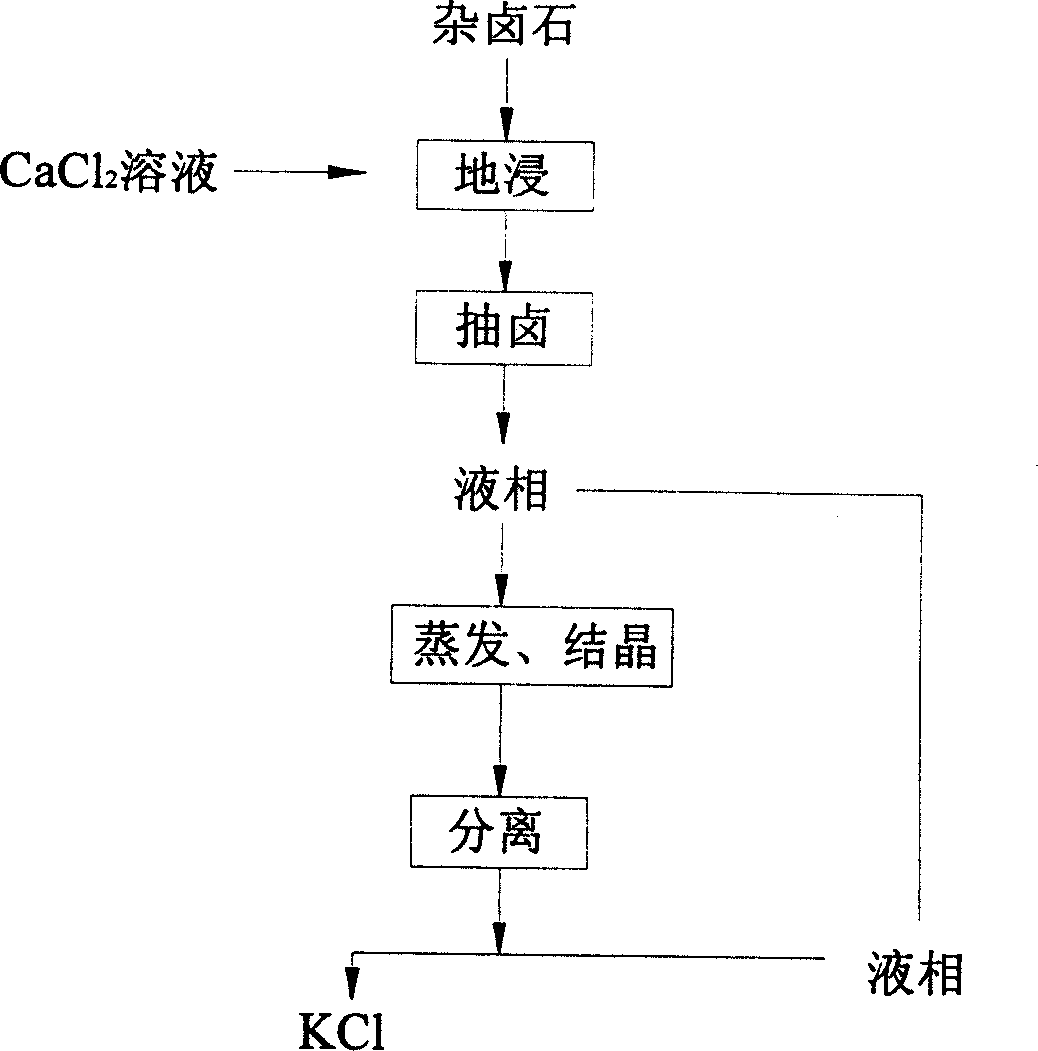

A mining method and polyhalite technology are applied in the direction of improving process efficiency, which can solve the problems of inability to achieve operating conditions and have not been developed and utilized, and achieve the effects of satisfactory development and utilization effect, wide applicability, and little impact on formation environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, the simulation experiment was carried out with Nongle polyhalite in Quxian County, Sichuan Province, and the K content in the ore was 14.8%. with 5% CaCl 2 Solution 2500ml is leaching and leaching 250g polyhalite, the ore particle size is 2mm, the percolation speed is 0.75m / d, the percolation column is Φ25mm×h400mm (the height of the sample is 300mm), and the obtained leachate is 2300ml, of which K + Concentration of 13.45g / l,, K + The leaching rate was 82.5%.

Embodiment 2

[0025] In this example, the simulation experiment is still carried out with Nongle polyhalite in Quxian County, Sichuan Province, and the K content in the ore is 15.15%. with 5% CaCl 2 Solution 1600ml is leached to extract 150g of polyhalite, the particle size of the ore sample is 5mm, the percolation speed is 0.55m / d, the percolation column is Φ25mm×h400mm (the height of the sample is 250mm), and the obtained leachate is 1420ml, of which K + Concentration of 13.05g / l,, K + The leaching rate is 81.55%.

Embodiment 3

[0027] In this example, the polyhalite in Dawenkou, Shandong Province was used for the simulation experiment, and the K content in the ore was 10.8%. with 5% CaCl 2 200g of polyhalite was obtained by leaching and leaching 2000ml of the solution, the ore particle size was 2mm, the percolation speed was 0.75m / d, the percolation column was Φ25mm×h400mm (the height of the sample was 300mm), and the resulting leachate was 1850ml, of which K + Concentration of 9.45g / l,, K + The leaching rate was 80.9%.

[0028] Example 3

[0029] In this example, the polyhalite in Dawenkou, Shandong Province was used for the simulation experiment, and the K content in the ore was 10.8%. with 5% CaCl 2 2500ml of the solution is leached to extract 200g of polyhalite, the ore particle size is 8mm, the percolation speed is 0.5m / d, the percolation column is Φ25mm×h400mm (the height of the sample is 300mm), and the obtained leachate is 2250ml, of which K + Concentration of 6.45g / l,, K + The leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com