Method for extracting gold from copper-containing gold oxide ore

A technology of copper oxidation and gold mining, applied in the field of hydrometallurgy, can solve the problems of high price, large consumption of reagents, and less industrial application, and achieve the effects of high gold recovery rate, reduced chemical cost, and low copper leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

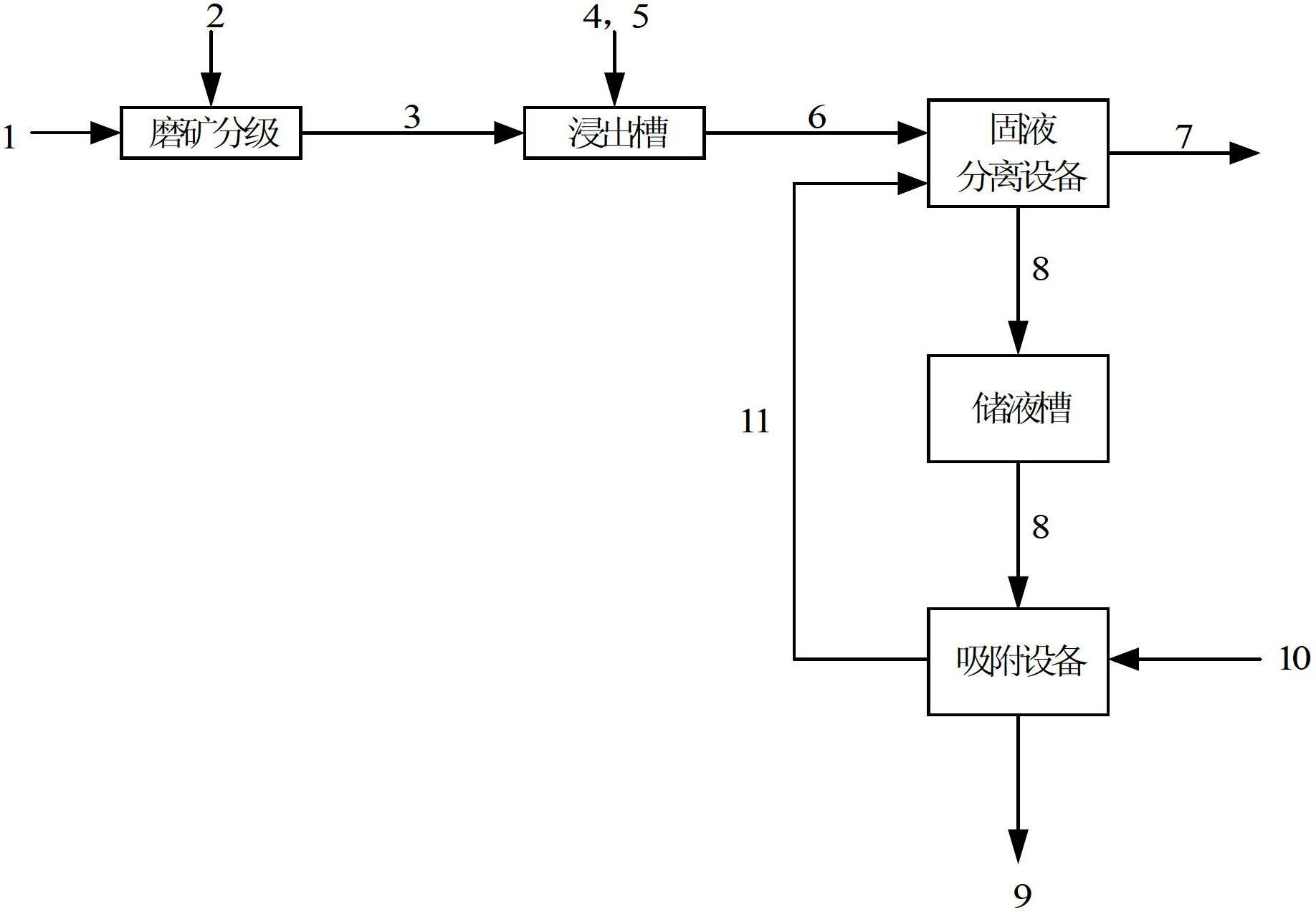

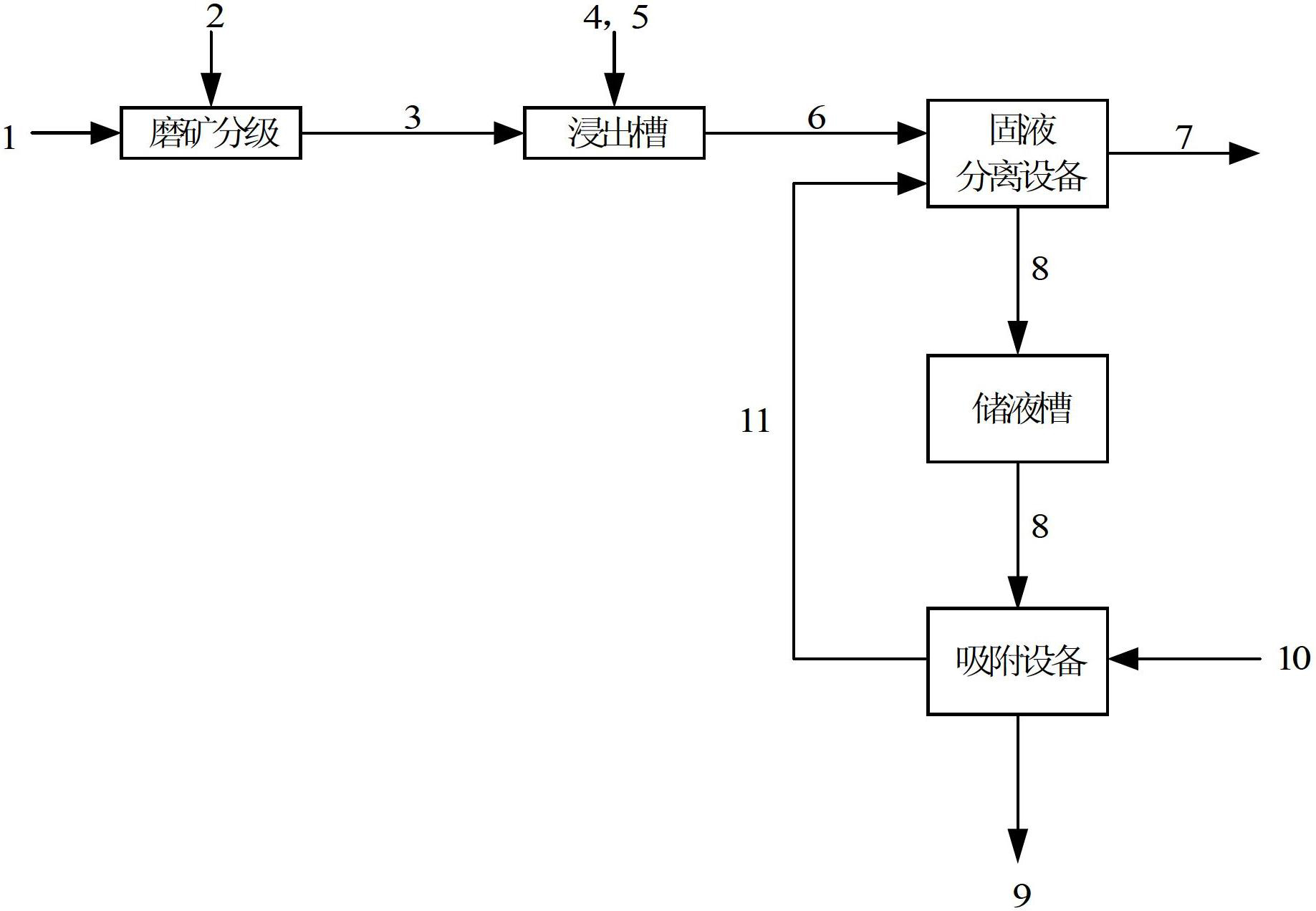

Method used

Image

Examples

example 1

[0028] Example 1: Raw ore Au2.62g / t, Cu0.62% copper-containing gold oxide ore, add lime 18kg / t~20kg / t, grind to -200 mesh to account for 95%, and make slurry with a liquid-solid ratio of 2:1 , add imidazole 0.3kg / t and NaCN1.0kg / t solution into the slurry into the leaching tank for gold dissolution reaction, leaching at room temperature for 72h, Au leaching rate is 70.56%, Cu leaching rate is 4.23%. The liquid-solid separation equipment for the pulp containing dissolved gold, the gold-containing liquid-precious liquid produced enters the liquid storage tank, and the leaching residue is discarded; the gold-containing precious liquid enters the adsorption equipment, and 15g / L of activated carbon is added to the adsorption device to recover the precious liquid The gold, Au adsorption rate reached 98.39%.

example 2

[0029] Example 2: The raw ore contains Au9.37g / t, Cu1.08% copper-containing oxidized gold ore, add lime 18kg / t~20kg / t, grind to -200 mesh to account for 95%, and make slurry with a liquid-solid ratio of 2 : 1. Add imidazoline 0.3kg and 1.0kg / tNaCN solution into the pulp into the leaching tank for gold-dissolving reaction, leaching at room temperature for 48-72h, the leaching rate of Au is 84.20%, and the leaching rate of Cu is 6.17%. The liquid-solid separation equipment for the pulp containing dissolved gold, the gold-containing liquid-precious liquid produced enters the liquid storage tank, and the leaching residue is discarded; the gold-containing precious liquid enters the adsorption equipment, and 15g / L of activated carbon is added to the adsorption device to recover the precious liquid The gold, Au adsorption rate reached 98.78%.

example 3

[0030] Example 3: The raw ore contains Au3.19g / t, Cu0.67% copper-containing oxidized gold ore, add lime 18kg / t~20kg / t, grind to -200 mesh to account for 95%, and adjust the slurry to a liquid-solid ratio of 2 : 1, add 0.3kg / t and 1.0kg / tNaCN solution of imidazole and imidazoline mixture of 2:1 into the pulp, enter the leaching tank, and carry out the gold dissolution reaction, leaching at room temperature for 48~72h, Au leaching rate 75.20%, Cu The leaching rate is 7.87%. The liquid-solid separation equipment for the pulp containing dissolved gold, the gold-containing liquid-precious liquid produced enters the liquid storage tank, and the leaching residue is discarded; the gold-containing precious liquid enters the adsorption equipment, and 15g / L of activated carbon is added to the adsorption device to recover the precious liquid The gold, Au adsorption rate reached 99.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com