Method for treating low-grade zinc oxide ores by wet method

A technology of zinc oxide ore and wet treatment, which is applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve the problems of poor quality of zinc oxide zinc oxide, achieve the effect of improving filtration performance and avoiding a large amount of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

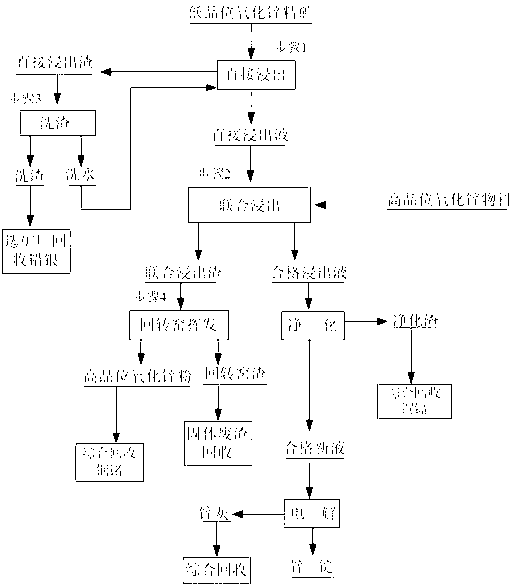

Method used

Image

Examples

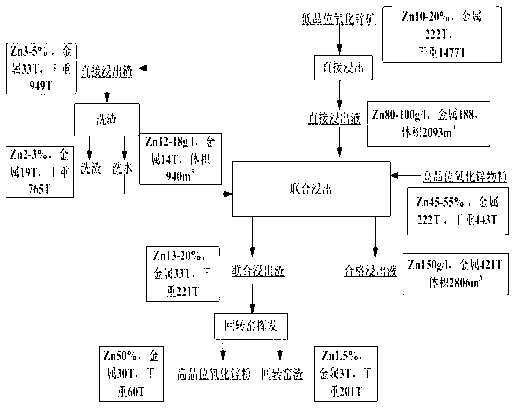

Embodiment 1

[0049] The low-grade zinc oxide ore in Nandan County, Guangxi is used, containing 15.03% zinc, 2.5% lead, 115g / t silver, and 67g / t germanium. High-grade zinc oxide ore is imported zinc oxide ore, containing 38.11% zinc, 5.76% lead, 103g / t germanium, and 41g / t indium. Zinc oxide ore is crushed and ball milled and put into the reaction tank together with zinc electrolytic waste liquid, leached with sulfuric acid with a concentration of 12-15%, the reaction temperature is 50~80°C, the final acid of leaching: 40~80g / L, the ore is controlled The liquid-solid ratio: 3~6:1, stirring reaction time: 60~100min. The leaching solution after the reaction is used for combined leaching, and the leaching residue is sent to the next step for slag washing. Put the high-grade zinc oxide ore into the reaction tank after the grinding treatment and the direct leaching output solution for leaching reaction. The initial acid of leaching: 40~80g / L, the stirring reaction time: 60~100min, and the final...

Embodiment 2

[0061] 1. Raw materials

[0062] The low-grade zinc oxide ore raw materials used come from local mines in Nandan, and the high-grade zinc oxide ore comes from imported Australian mines. The average composition of raw materials is shown in Table 1 and Table 2.

[0063] Table 1 Low-grade zinc oxide ore

[0064] element Zn Fe SiO2 Pb Sb Ag content(%) 15.03 31.6 28.2 2.5 0.5 115g / t

[0065] Table 2 High-grade zinc oxide materials

[0066] element Zn Fe SiO2 Pb In Ge content(%) 50.11 17.3 12.7 4.38 86g / t 157g / t

[0067] 2. Test indicators

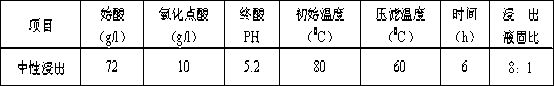

[0068] 2.1 Direct leaching

[0069] 2.1.1 Leaching technical conditions

[0070]

[0071] 2.1.2 Components of direct leaching supernatant (g / l)

[0072] Zn Fe acidity Solid content 89 0.017 72 ≤1.5

[0073] 2.1.3 Direct leaching slag (%)

[0074] Zn Pb H2O 3.47 3.06 29

[0075] 2.1.4 Leaching rate: 88%, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com