Modified zeolite organic matter composite agent for synchronous nitrogen and phosphorus removal of sewage, and preparation method, application and application method of modified zeolite organic matter composite agent

A simultaneous nitrogen and phosphorus removal and modified zeolite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of poor treatment effect of ammonia nitrogen and nitrate nitrogen, treatment Unstable effect, high operating cost and other problems, to achieve the effect of improving the removal effect, improving the removal efficiency, and broadening the wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw materials: Artificial zeolite is purchased from Nanjing Chemical Reagent Co., Ltd., batch number is 11060120497, the particle size of artificial zeolite is 60-80 mesh, white particles, a kind of hydrated sodium aluminosilicate salt formed by mixing and melting clay, silica sand, sodium carbonate, etc., insoluble in water. Commercially available cetyltrimethylammonium bromide white powder and polyaluminum ferric chloride (PAFC).

[0038] The preparation process of modified zeolite organic compound agent (new coagulant):

[0039] (1) cetyltrimethylammonium bromide is configured into mass concentration and is respectively 5g / L, 10g / L, 20g / L, 30g / L, 40g / L solution;

[0040] (2) configuring lanthanum chloride into a rare earth solution with a mass concentration of 0.5%;

[0041] (3) Dry the 60-80 mesh artificial zeolite at 100°C for 4 hours;

[0042] (4) Get 5 Erlenmeyer flasks, add the cetyltrimethylammonium bromide solution that concentration is 5g / L, 10g / L, 20g / L, ...

Embodiment 2

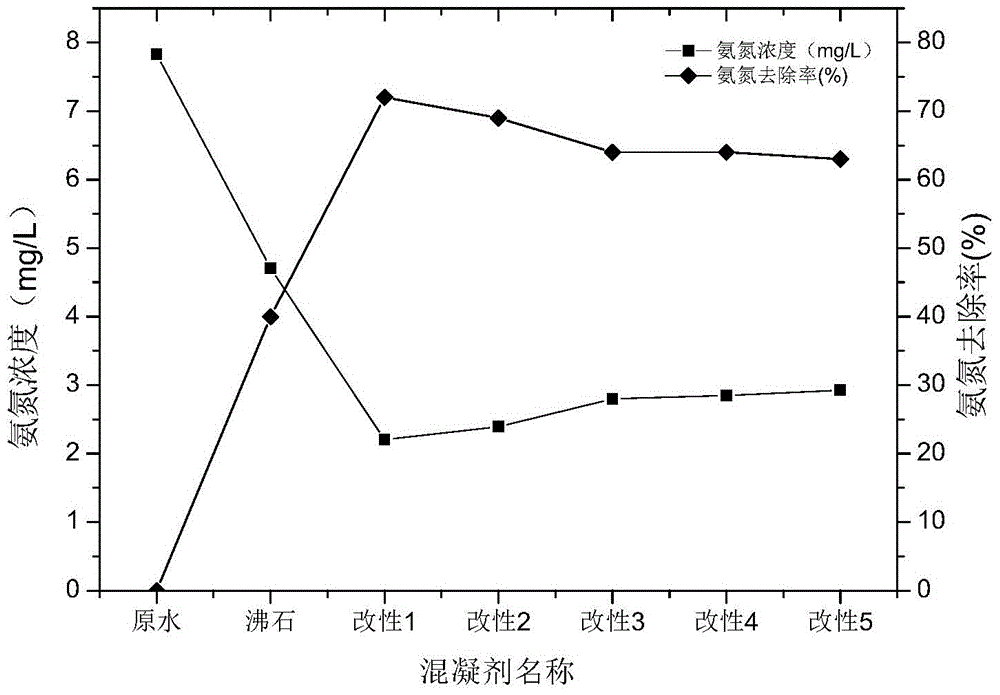

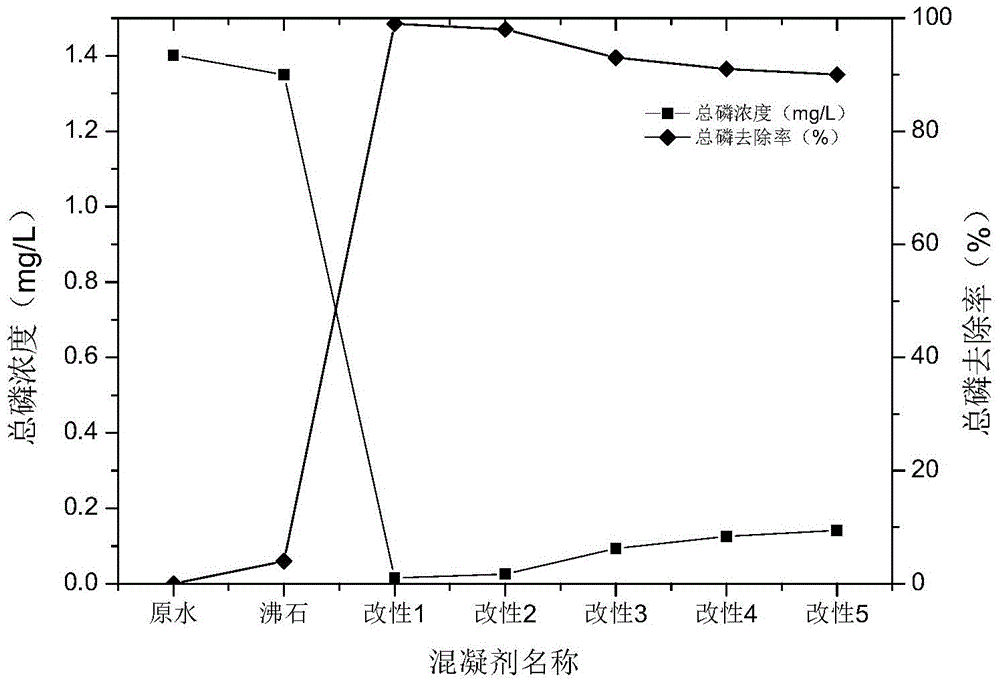

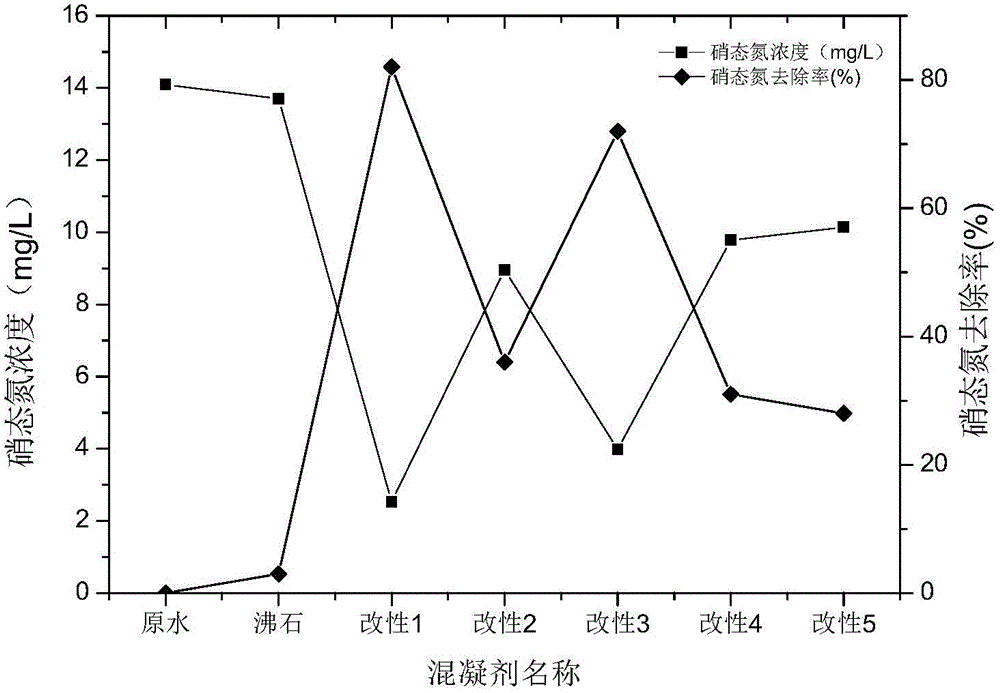

[0045] Prepare the simulated sewage containing ammonia nitrogen 8mg / L, nitrate nitrogen 14mg / L and phosphorus 1.5mg / L, add the modified zeolite organic compound (modified 1) prepared in embodiment 1 to the simulated sewage, coagulant The dosage is 200mg / L. Use a mixer to quickly and fully stir (300r / min) for 30 seconds, then slowly stir (30r / min) for 25 minutes, and take the supernatant after standing for 30min. The concentration of ammonia nitrogen in the supernatant was determined by Nessler's reagent spectrophotometry, the concentration of nitrate nitrogen by thymol spectrophotometry, and the concentration of phosphorus by molybdate spectrophotometry. The other types of modified zeolite organic complex agents (ie, modified 2 to modified 5 prepared in Example 1) were also measured according to the method above to determine the concentration of the supernatant after corresponding treatment. Then separately measure the removal effect on simulated sewage when there is only zeo...

Embodiment 3

[0048] The biochemical effluent of a sewage treatment plant is taken, and its water quality indicators are: the concentration of ammonia nitrogen is 7.56mg / L, the concentration of total phosphorus is 1.12mg / L, and the concentration of nitrate nitrogen is 10.32mg / L.

[0049] Modified 1 (i.e. the modified zeolite organic compound prepared when the mass concentration of cetyltrimethylammonium bromide was 5g / L) was prepared according to the method of Example 1, and 200 mg of the modified zeolite organic compound prepared was weighed In a 2L beaker, add 1L of the effluent from the sewage treatment plant, stir it fully (300r / min) for 30 seconds with a mixer, then stir slowly (30r / min) for 25 minutes, and take the supernatant after standing for 1h Determination. The removal rate of ammonia nitrogen can reach 70.21%, the removal rate of total phosphorus can reach 92.35%, and the removal rate of nitrate nitrogen can reach 52.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com