Sludge charcoal for repairing heavy metal contaminated soil and preparation method of sludge charcoal

A technology of polluting soil and biochar, applied in biofuels, soil conditioning materials, chemical instruments and methods, etc., can solve secondary pollution and other problems, and achieve the effects of economic feasibility, stress reduction, and wide-ranging sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

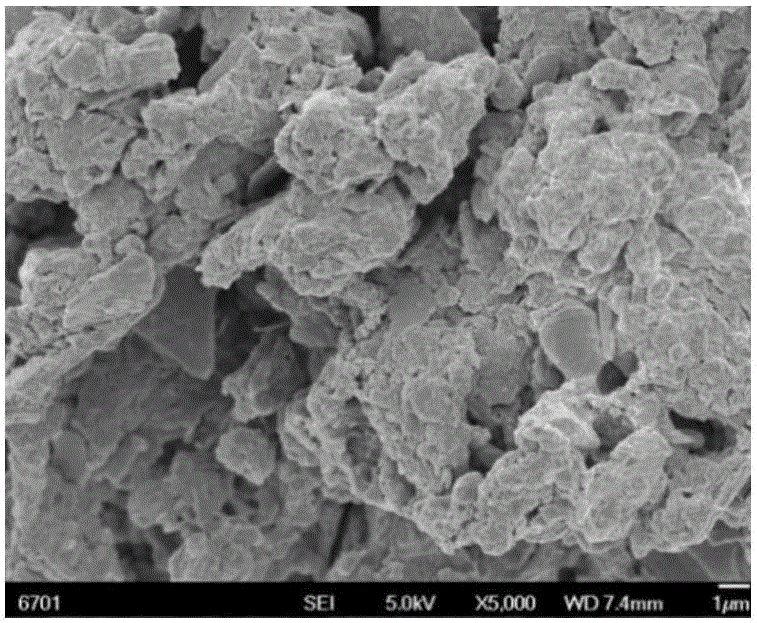

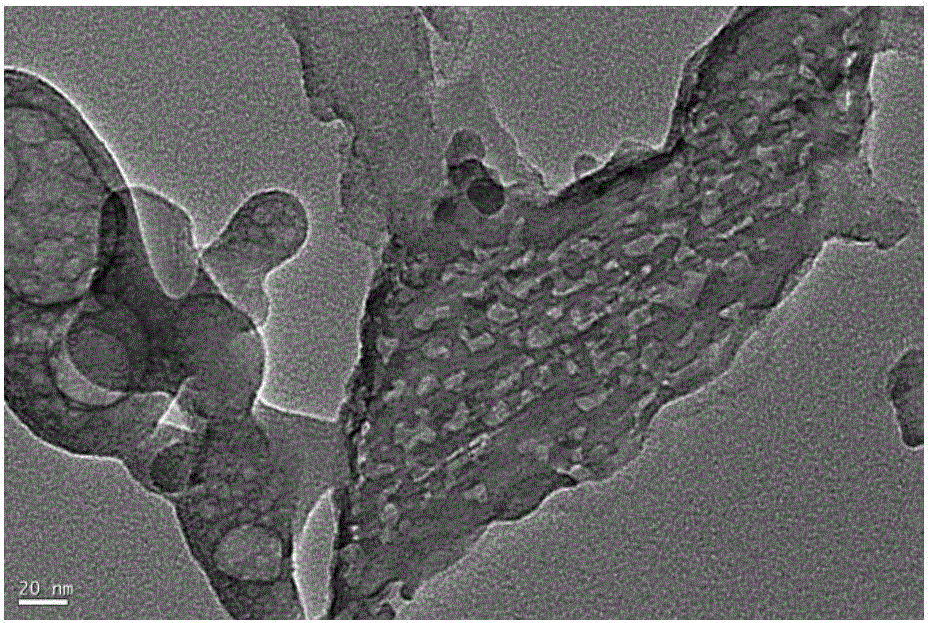

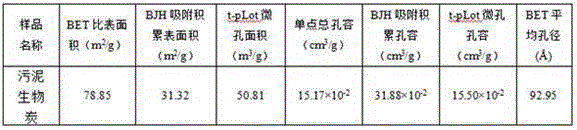

Image

Examples

preparation example Construction

[0037] A method for preparing sludge biochar for remediation of heavy metal contaminated soil, characterized in that it comprises the following steps:

[0038] A. Biological and physical drying

[0039] The concentrated sludge is dried biologically and physically, and the concentrated sludge is piled up for aerobic fermentation. During the stacking process, it is ventilated and dried. According to the weight of the concentrated sludge, the ventilation intensity is 120-180 L·( h·kg) -1 , ventilation and drying for 120 hours, and the water content of the concentrated sludge after biological and physical drying is controlled at 52-60%;

[0040] B. Drying and granulation again

[0041] The dried concentrated sludge in step A is crushed, the crushed particle size is ≤5mm, and the weight ratio of palygorskite is 5-10%, and the rest is concentrated sludge. Dry and granulate in a converter at ℃ for 8 hours to obtain granules with a particle size of 1-3mm;

[0042] C. Pyrolysis and ...

Embodiment 1

[0049] A method for preparing sludge biochar for remediation of heavy metal contaminated soil, comprising the steps of:

[0050] A. Biological and physical drying

[0051] The concentrated sludge is dried biologically and physically, and the concentrated sludge is piled up for aerobic fermentation. During the stacking process, it is ventilated and dried. According to the weight of the concentrated sludge, the ventilation intensity is 120L (h kg) -1 , ventilation and drying for 120 hours, and the water content of the concentrated sludge after biological and physical drying is controlled at 52-60%;

[0052] B. Drying and granulation again

[0053] The dried and concentrated sludge in step A is crushed, the crushed particle size is ≤5 mm, and the weight ratio of palygorskite is 5% and the concentrated sludge is 95%. The mixture is fully mixed and stirred evenly, and the mixed material is heated at 80-120°C Dry and granulate in a converter for 8 hours to obtain granules with a p...

Embodiment 2

[0059] A method for preparing sludge biochar for remediation of heavy metal contaminated soil, comprising the steps of:

[0060] A. Biological and physical drying

[0061] The concentrated sludge is dried biologically and physically, and the concentrated sludge is piled up for aerobic fermentation. During the stacking process, it is ventilated and dried. According to the weight of the concentrated sludge, the ventilation intensity is 180 L·( h·kg) -1 , ventilation and drying for 120 hours, and the water content of the concentrated sludge after biological and physical drying is controlled at 52-60%;

[0062] B. Drying and granulation again

[0063] The dried concentrated sludge in step A is crushed, the crushed particle size is ≤5mm, and the weight ratio of palygorskite is 8% and the concentrated sludge is 92%. The mixture is fully mixed and stirred, and the mixed material is heated at 80-120°C. Dry and granulate in a converter for 8 hours to obtain granules with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com