Soil remediation agent

The technology of a soil remediation agent and sodium-based bentonite is applied in the field of soil pollution remediation, which can solve the problems of soil structure damage, loss of nutrient elements, and high processing cost, and achieves the effects of high adsorption value, increased adsorption capacity, and avoidance of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

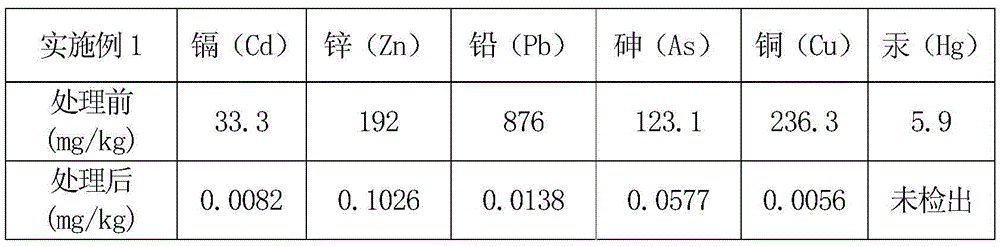

Embodiment 1

[0035] The test soil was collected from an area contaminated by heavy metals. The content of heavy metals in the surface of the soil was higher than the third-level standard of "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution:

[0036] (a) Sampling from the soil, testing according to the solid waste "Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), using an overturning shaker to conduct a leaching test on the soil to detect the heavy metal concentration of the soil before restoration;

[0037] (b) Preparation of soil remediation agent: using a mixture of straw and calcium oxide as raw materials, the mass ratio of the straw and calcium oxide is 20:1, and the system pressure is 20kPa and the pyrolysis temperature is 500℃. Solve for 30 minutes and obtain biomass charcoal powder with a particle size of 3mm or less through grinding treatment; obtain sodium bentonite with an alkalinity coefficie...

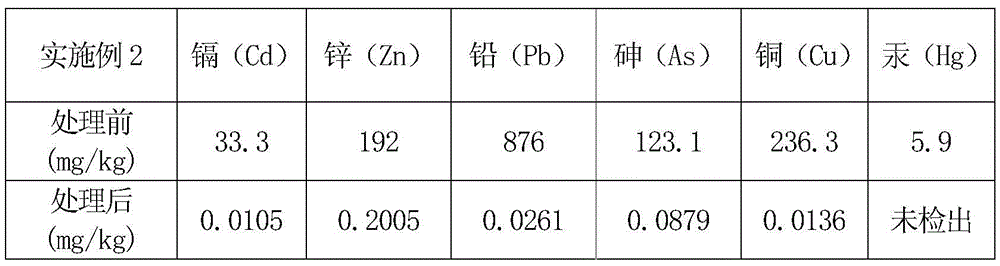

Embodiment 2

[0050] The test soil was collected from an area contaminated by heavy metals. The content of heavy metals in the soil surface of this area was higher than the third-level standard of "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution:

[0051] (a) Sampling from the soil, testing according to the solid waste "Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), using an overturning shaker to conduct a leaching test on the soil to detect the concentration of heavy metals in the soil before restoration;

[0052] (b) Preparation of soil remediation agent: using a mixture of straw and calcium oxide as raw materials, the mass ratio of the straw and calcium oxide is 20:1, and the system pressure is 20kPa and the pyrolysis temperature is 500℃. Solve for 30 minutes and obtain biomass charcoal powder with a particle size of 3mm or less through grinding treatment; obtain sodium bentonite with an alkalinity...

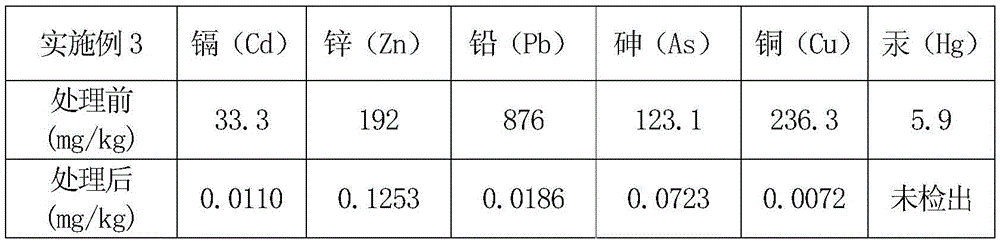

Embodiment 3

[0065] The test soil was collected from an area contaminated by heavy metals. The content of heavy metals in the surface of the soil was higher than the third-level standard of "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution:

[0066] (a) Sampling from the soil, testing according to the solid waste "Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), using an overturning shaker to conduct a leaching test on the soil to detect the concentration of heavy metals in the soil before restoration;

[0067] (b) Preparation of soil remediation agent: using a mixture of straw and calcium oxide as raw materials, the mass ratio of the straw and calcium oxide is 20:1, and the system pressure is 20kPa and the pyrolysis temperature is 500℃. Solve for 30 minutes and obtain biomass charcoal powder with a particle size of 3mm or less through grinding treatment; obtain sodium bentonite with an alkalinity coeff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com