Formula of butyronitrile rubber/polyvinyl chloride co-mixed rubber ethanol resistance gasoline rubber pipe

A technology of polyvinyl chloride and nitrile rubber, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., which can solve the problems of poor ethanol gasoline resistance of hoses

Active Publication Date: 2010-08-18

TIANJIN PENGYI GRP CO LTD

View PDF0 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a formula of ethanol-resistant gasoline rubber hose, to solve the shortcoming of the hose's poor resistance to ethanol gasoline, it is proposed to use nitrile rubber / polyvinyl chloride (NBR / PVC) as the main material through formula design to meet the current product requirements. requirements for use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010]

[0011]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

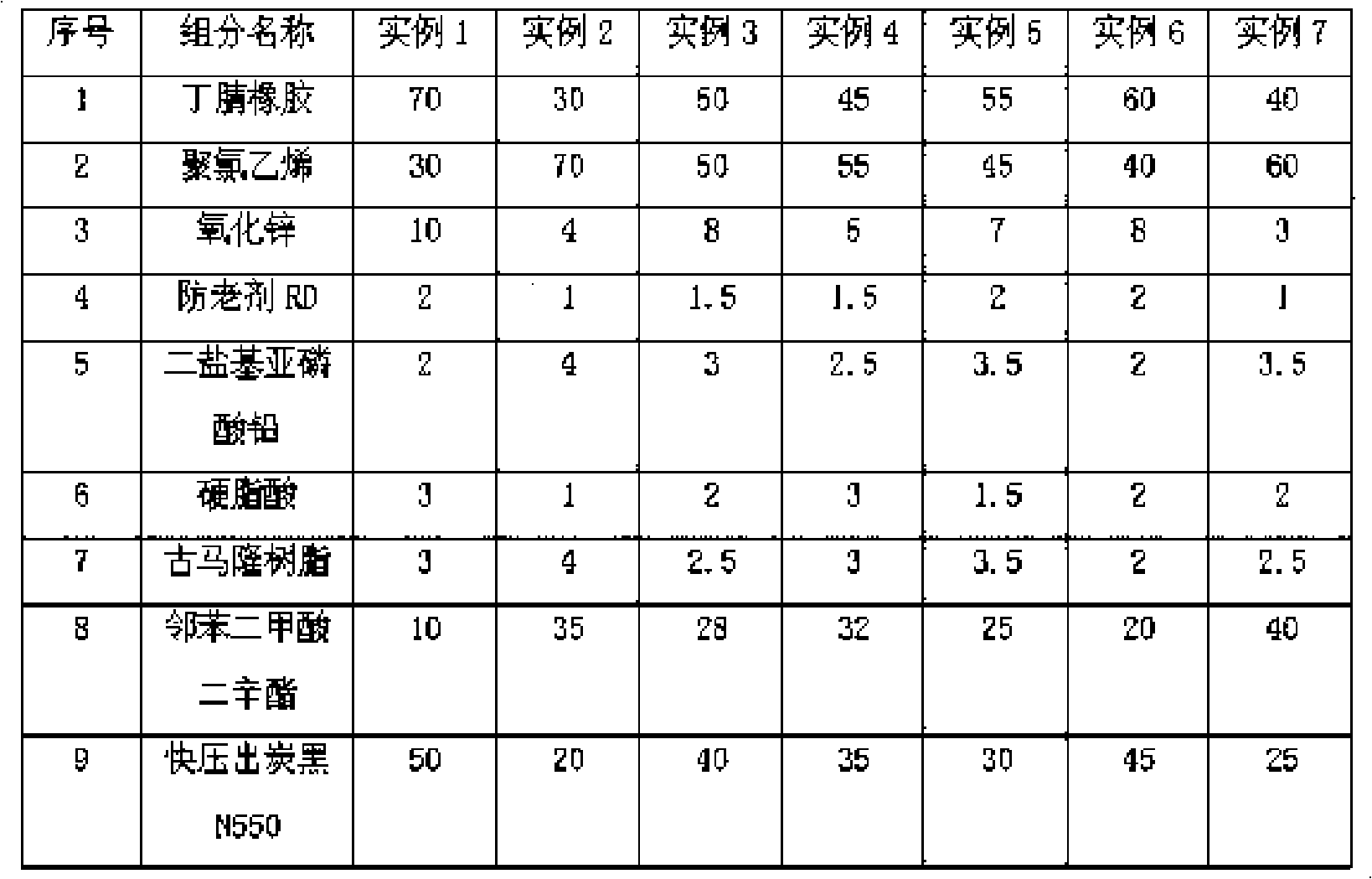

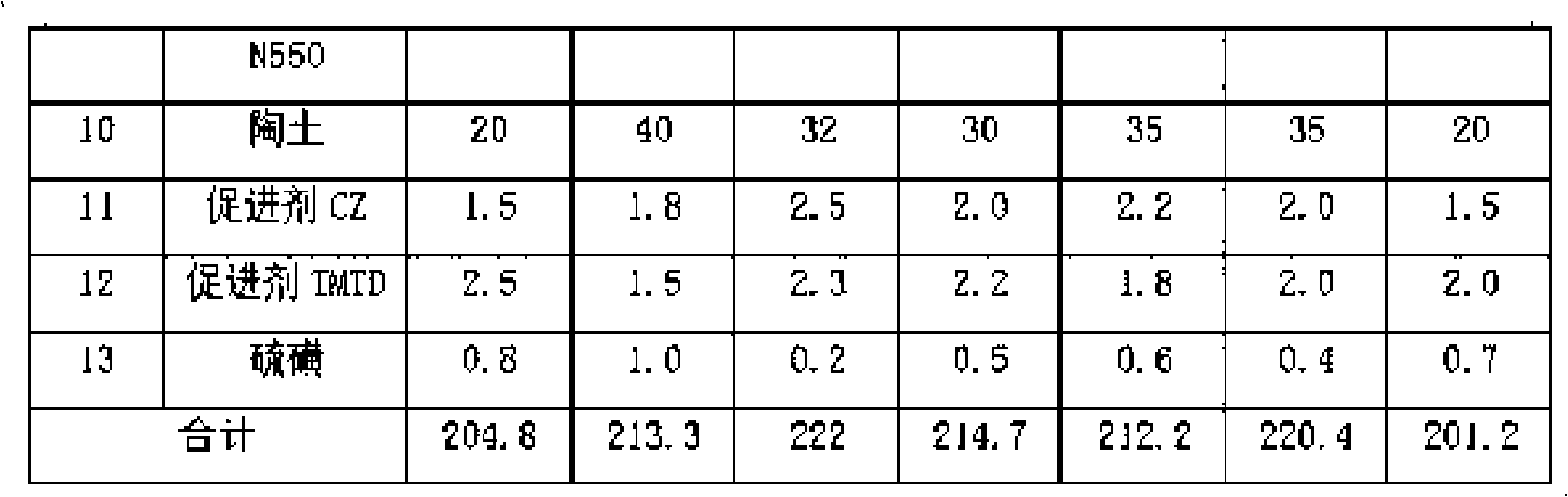

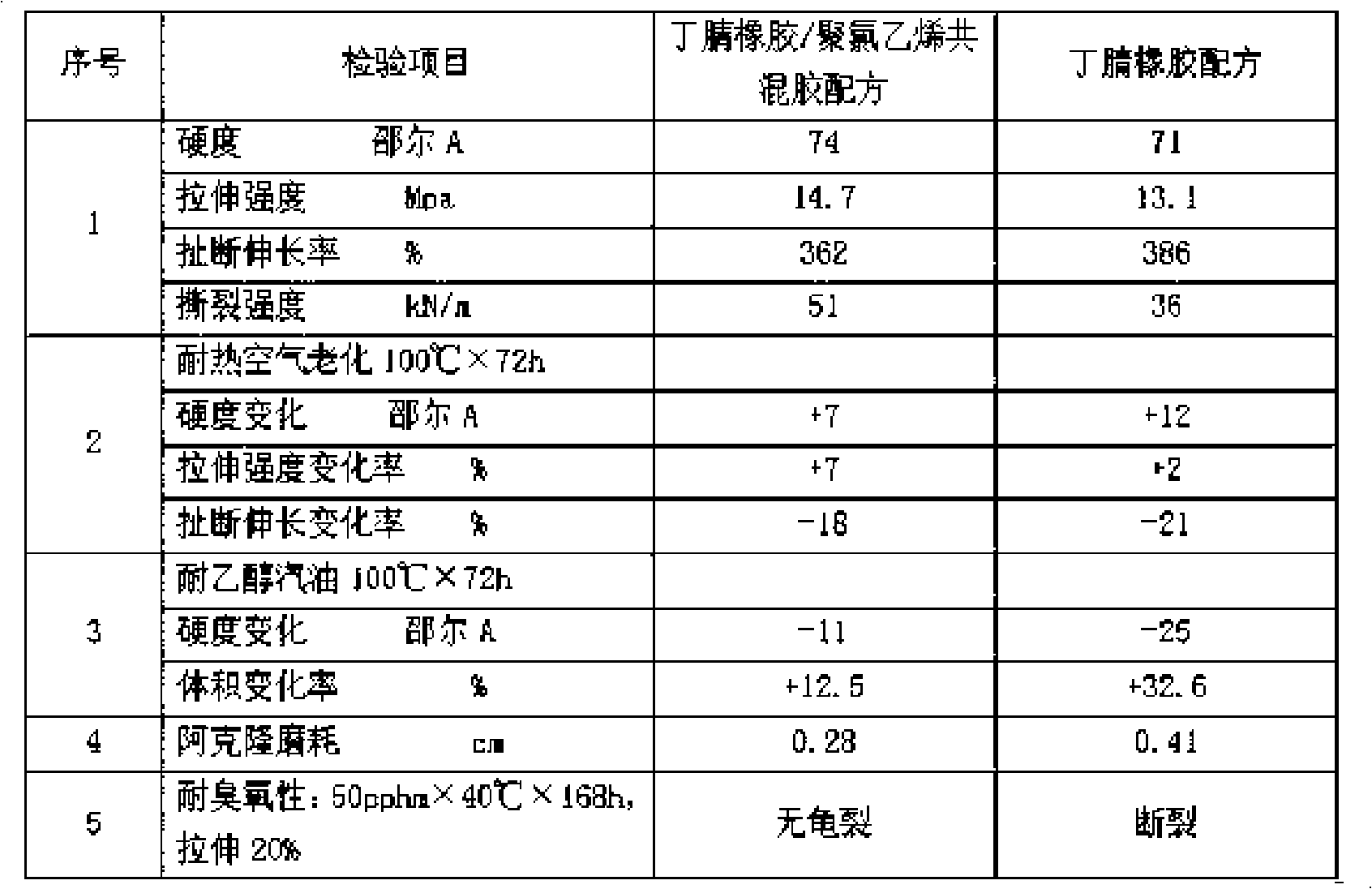

The invention relates to a formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber ethanol resistant gasoline rubber pipe, comprising the following components in parts by weight: 30-70 parts of butyronitrile rubber, 70-30 parts of polyvinyl chloride, 3-10 parts of zinc oxide, 1-2 parts of anti-aging agent RD, 2-4 parts of dibasic lead phosphate, 1-3 parts of stearic acid, 2-4 parts of coumarone-indene resin, 10-40 parts of dioctyl phthalate, 20-50 parts of fast extruding furnace black (N550), 20-40 parts of figuline and 1.5-2.5 parts of an accelerating agent CZ. Through the performance contrastive analysis of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber and the formula of the butyronitrile rubber, the comprehensive performance of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber is better with low cost, which can satisfy the requirements of the traditional ethanol resistant gasoline.

Description

technical field [0001] The invention relates to the technical field of rubber formulations, in particular to a formulation of a nitrile rubber / polyvinyl chloride (NBR / PVC) blend rubber resistant to ethanol gasoline rubber hose. Background technique [0002] With the deepening of people's understanding of the global energy crisis and environmental protection, the fuel gasoline used in automobiles is gradually replaced by ethanol. It does not affect the driving performance of the car, and can effectively improve the performance and quality of oil products, and at the same time reduce the emission of major pollutants such as carbon monoxide and hydrocarbons (after adding 10% fuel ethanol to gasoline, the carbon monoxide emission in automobile exhaust can be reduced. decrease by more than 30%, and the emission of hydrocarbons by more than 10%). As a new type of clean fuel, ethanol gasoline is currently the development focus of renewable energy http: / / baike.baidu.com / view / 9292.h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L9/02C08L27/06C08K13/02F16L11/06

Inventor 张洪起张桂林

Owner TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com