Sound control system for steel roof decks

a sound control system and steel roof technology, applied in the direction of roofing, building roofs, building components, etc., can solve the problems of generating noise, limited insulation thickness, potential rotation and bending problems of fasteners, etc., and achieve the effect of eliminating the noise created by the movement of the deck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

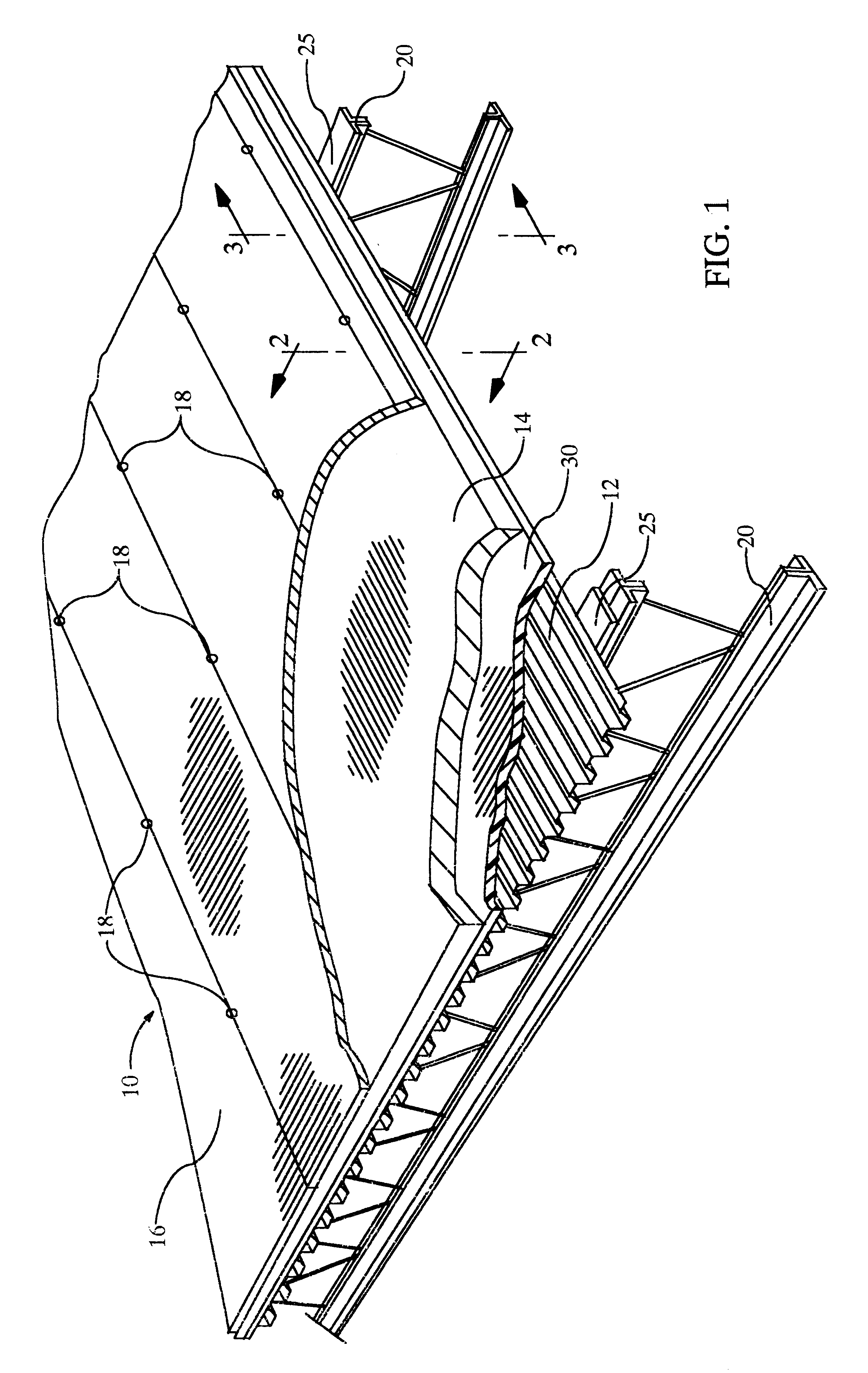

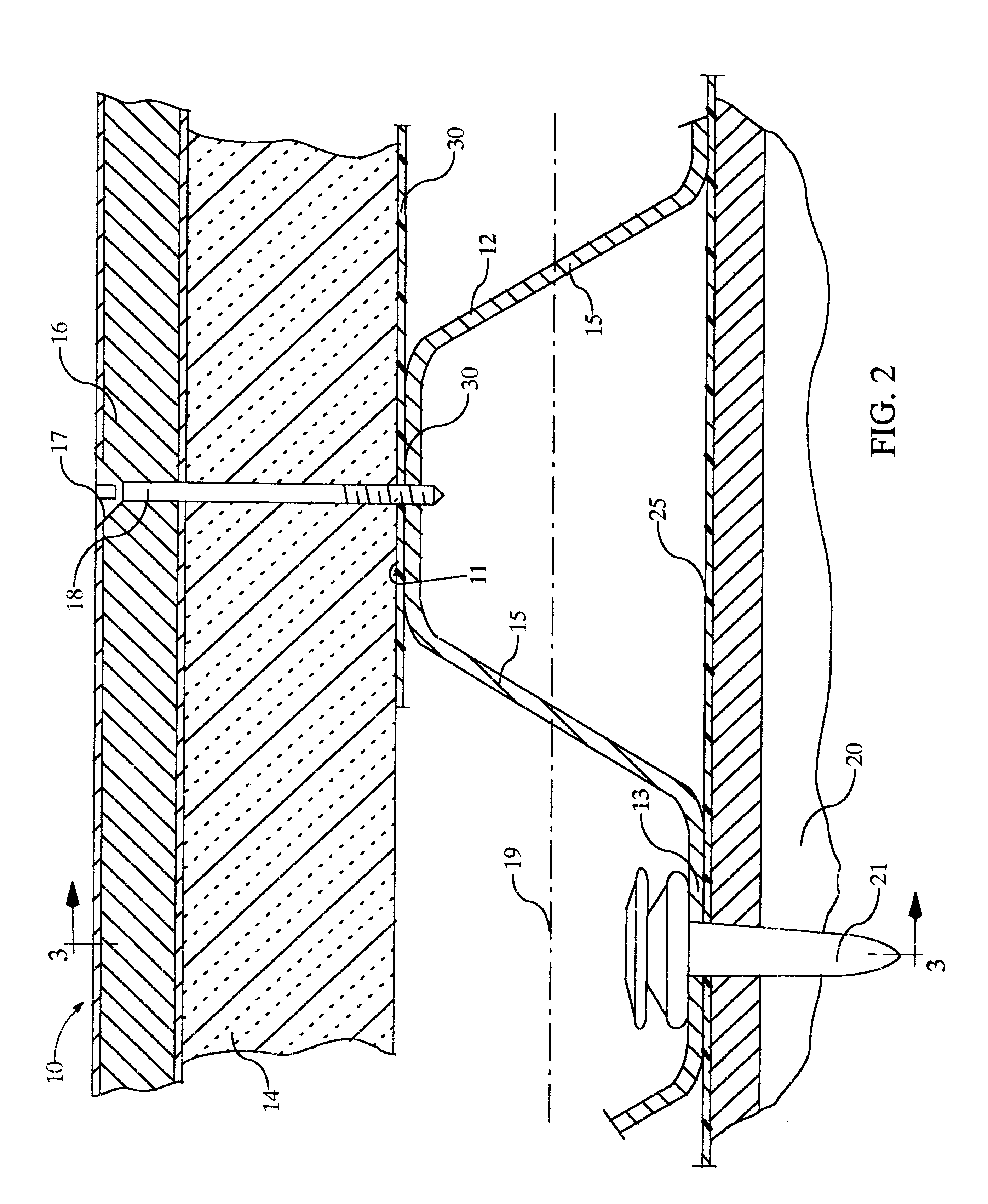

Referring to FIGS. 1, 2 and 3 of the drawings, the numeral 10 generally designates a steel roof deck comprising a plurality of sheets 12 of corrugated material, optional sheets 14 of foamed insulation material and sheets 16 of rigid mineral board, the sheets of mineral board 16 being secured by screws 18 to ridges 11 of the corrugated sheets, as will be hereinafter more fully explained. Valleys 13 of the corrugated sheet are secured to span across space between purlins 20, which in the illustrated embodiment are formed by open web steel joists. Valleys 13 are preferably secured to purlins 20 by powder actuated drive pins 21, self drilling screws or by welding.

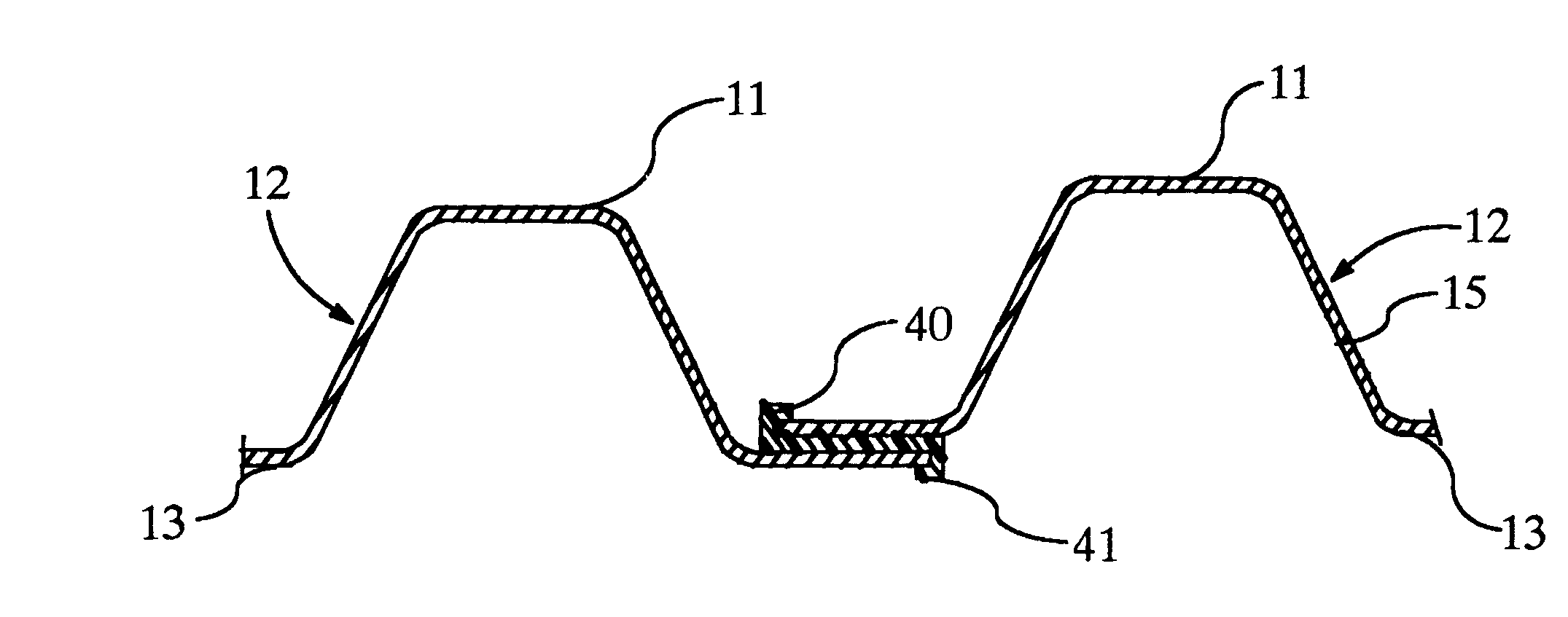

Corrugated sheet 12 preferably has flat ridge portions 11 and flat valley portions 13 of substantially equal length joined by connector portions 15 providing straight, parallel, regular and equally curved ridges and hollows. As best illustrated in FIG. 2, this configuration has a substantially equal distribution of surface area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com