Cement-based adhesive

A kind of adhesive and cement-based technology, which is applied in the field of cement-based adhesives, can solve the problems of friction between shoes and tile surfaces, high-heeled shoes and tile surfaces, high impact noise, affecting the quietness of public places, and high elastic modulus, so as to reduce elasticity Modulus, reduce the shear stress of the tile interface, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

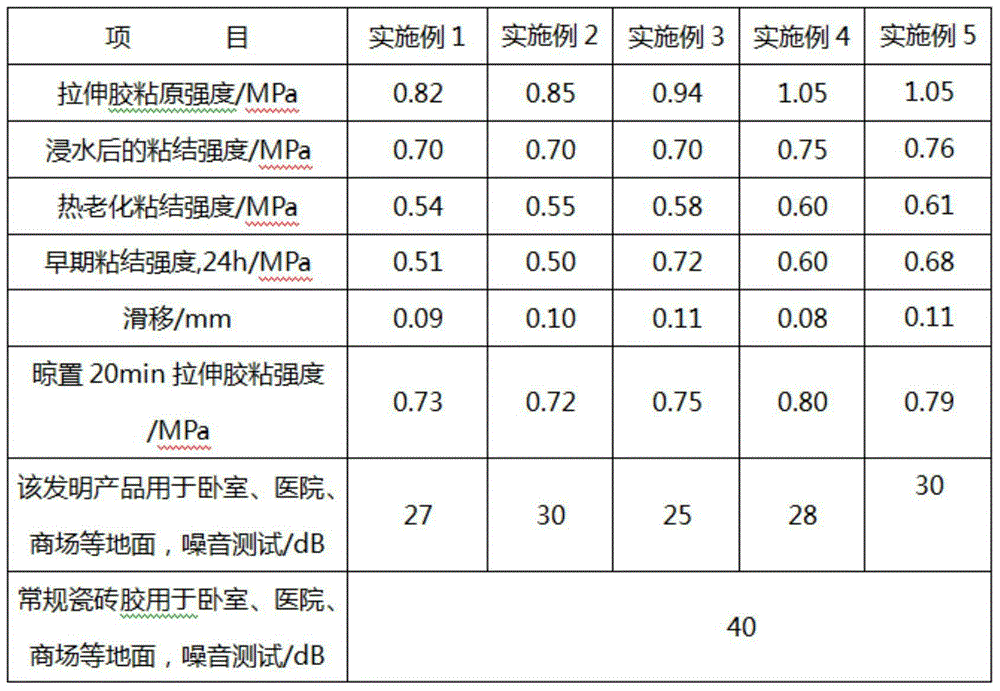

Examples

Embodiment 1

[0023] Embodiment 1, a kind of cement-based adhesive described in the embodiment of the present invention, this adhesive comprises inorganic gelling agent, elastic modulus filler, sand and dry powder mortar additive, the mass percentage of each component in adhesive It is: 35% of inorganic gel agent, 15% of elastic modulus filler, 47% of sand, 3% of dry powder mortar additive, and the rest is water.

[0024] Further, the inorganic gelling agent is Portland cement. Further, the elastic modulus filler is a mixture of rubber particles, polystyrene particles, and vitrified microspheres, and the mixing mass ratio of these three is 1:1:1; the elastic modulus filler has a fineness of 20 meshes; wherein, The rubber particles are rubber particles that have been surface-treated with a silane coupling agent.

[0025] Further, the sand is washed sand, and the particle size of the sand is 0-4.75mm. Further, the dry powder mortar additive is composed of redispersible latex powder, cellulo...

Embodiment 2

[0028] Embodiment 2, a kind of cement-based adhesive described in the embodiment of the present invention, this adhesive comprises inorganic gelling agent, elastic modulus filler, sand and dry powder mortar additive, the mass percentage of each component in adhesive It is: 40% of inorganic gel agent, 23% of elastic modulus filler, 32.9% of sand, 4.1% of dry powder mortar additive, and the rest is water.

[0029] Further, the inorganic gelling agent is Portland cement. Further, the elastic modulus filler is a mixture of 15% of rubber particles and 7% of vitrified microbeads, and the above percentages are all percentages by mass; the fineness of the elastic modulus filler is 30 mesh; wherein, the rubber particles are made of silane coupling agent Rubber particles after surface treatment.

[0030] Further, the sand is quartz sand, and the particle size of the sand is 0-4.75mm.

[0031] Further, the dry powder mortar additive is composed of redispersible latex powder, cellulose ...

Embodiment 3

[0034] Embodiment 3, a cement-based adhesive described in the embodiment of the present invention, the adhesive includes inorganic gelling agent, elastic modulus filler, sand and dry powder mortar additives, the mass percentage of each component in the adhesive It is: 45% of inorganic gel agent, 25% of elastic modulus filler, 25.2% of sand, 4.8% of dry powder mortar additive, and the rest is water.

[0035] Further, the inorganic gelling agent is a mixture of 30% Portland cement and 15% sulphoaluminate cement, and the above percentages are all mass percentages. Further, the elastic modulus filler is rubber particles; the fineness of the elastic modulus filler is 20-80 mesh; wherein, the rubber particles are rubber particles after surface treatment with a silane coupling agent.

[0036] Further, the sand is quartz sand, and the particle size of the sand is 0-4.75mm.

[0037] Further, the dry powder mortar additive is composed of redispersible latex powder, cellulose ether, sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com