Active carbon ceramic with selectivity and preparation method thereof

An activated carbon and selective technology, which is applied in the field of activated carbon ceramics and its preparation, can solve the problems of occupying a large space, dust pollution, high cost and price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

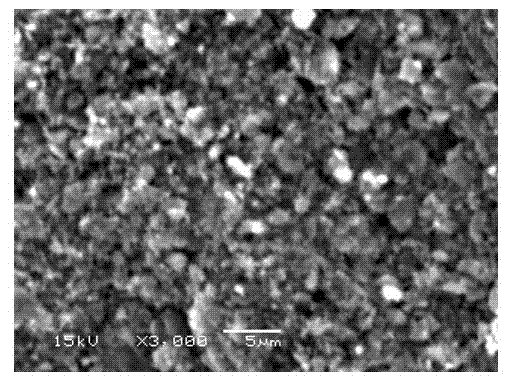

Image

Examples

Embodiment 1

[0049] The selective activated carbon ceramic of this embodiment is made of the following raw materials in parts by weight: sludge 30, kaolin 2, and iron powder 1.

[0050] The preparation method is as follows:

[0051] (1) Mix the raw materials of biological activated carbon ceramics according to the above formula, use extrusion or disc granulation to make and shape, and then dry and shape;

[0052] (2) Place the blank obtained in step (1) in a high-temperature oven for firing under vacuum, and the vacuum in the high-temperature oven is -0.08-0.09 Mpa. The temperature of the oven is increased to 300°C at a heating rate of 90°C / h for 1.5 hours, and the volatile odorous gas generated during this period is passed into the gas furnace for combustion, and its heat is used for self-preservation;

[0053] (3) The temperature of the oven is raised to 740°C at a heating rate of 90°C / h for 3 hours; then the temperature is lowered to room temperature at a cooling rate of 150°C / h to obtain a cer...

Embodiment 2

[0057] The selective activated carbon ceramic of this embodiment is made of the following raw materials in parts by weight: sludge 50, kaolin 10, copper powder 3, and wheat bran 8.

[0058] The preparation method is as follows:

[0059] (1) Mix the raw materials of biological activated carbon ceramics according to the above formula, use extrusion or disc granulation to make and shape, and then dry and shape;

[0060] (2) Place the blank obtained in step (1) in a high-temperature oven for firing under the protection of nitrogen. The pressure of the nitrogen introduced into the high-temperature oven is 0.1-0.12Mpa. The temperature of the oven is raised to 300°C at a heating rate of 100°C / h for 1.5 hours. The volatile odorous gas produced during this period is passed into the gas furnace for combustion, and its heat is used for self-preservation;

[0061] (3) The temperature of the oven is raised to 750°C at a heating rate of 100°C / h for 2.5 hours; then the temperature is lowered to room...

Embodiment 3

[0065] The selective activated carbon ceramic of this embodiment is made of the following raw materials in parts by weight: sludge 30-70, kaolin 2-15, Zn 1-5, bran 8-12, and calcium carbonate 3-5.

[0066] The preparation method is as follows:

[0067] (1) Mix the raw materials of biological activated carbon ceramics according to the above formula, use extrusion or disc granulation to make and shape, and then dry and shape;

[0068] (2) Place the blank obtained in step (1) in a high-temperature oven for firing under the protection of nitrogen. The pressure of the nitrogen introduced into the high-temperature oven is 0.1-0.12Mpa. The temperature of the oven is increased to 305°C at a heating rate of 110°C / h for 1 hour. The volatile odorous gas generated during this period is passed into the gas furnace for combustion, and its heat is used for self-preservation;

[0069] (3) The temperature of the oven is raised to 760°C at a heating rate of 110°C / h for 2 hours; then the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com