Waste gas integrated treatment device

A technology for comprehensive treatment and exhaust gas, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

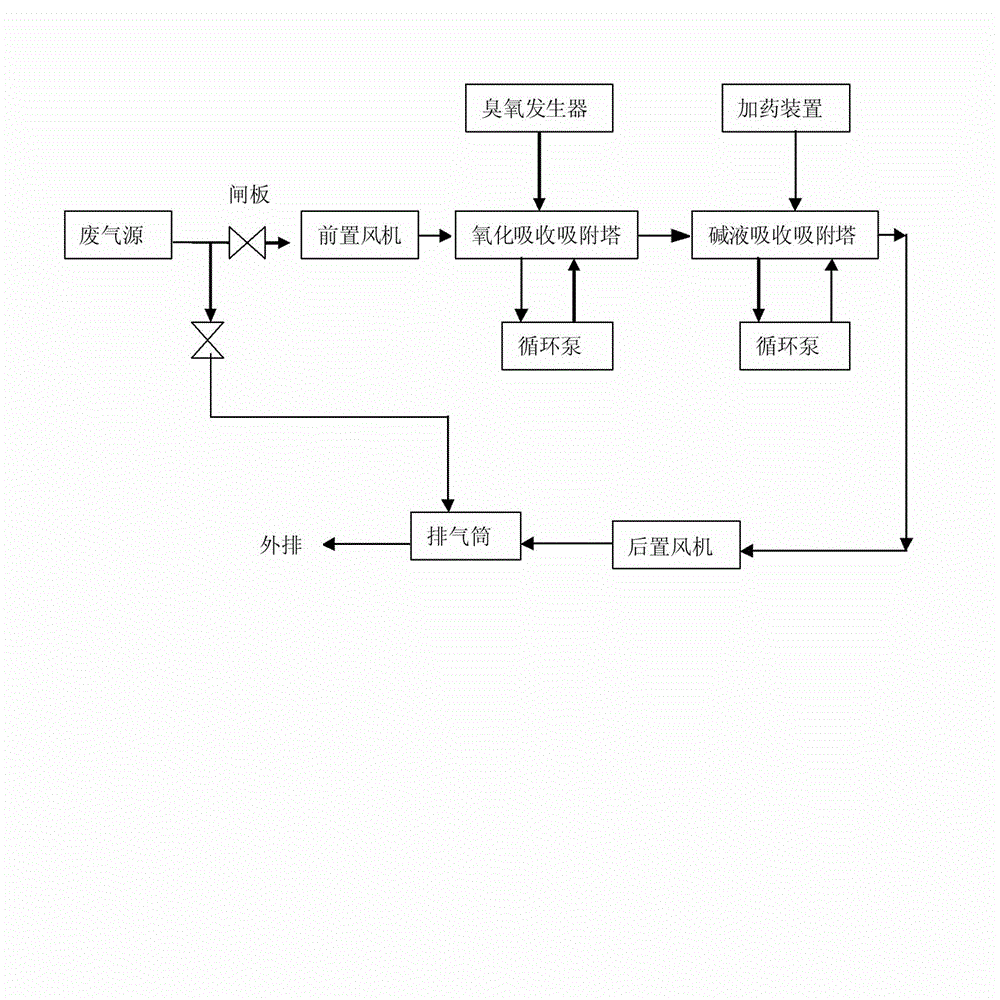

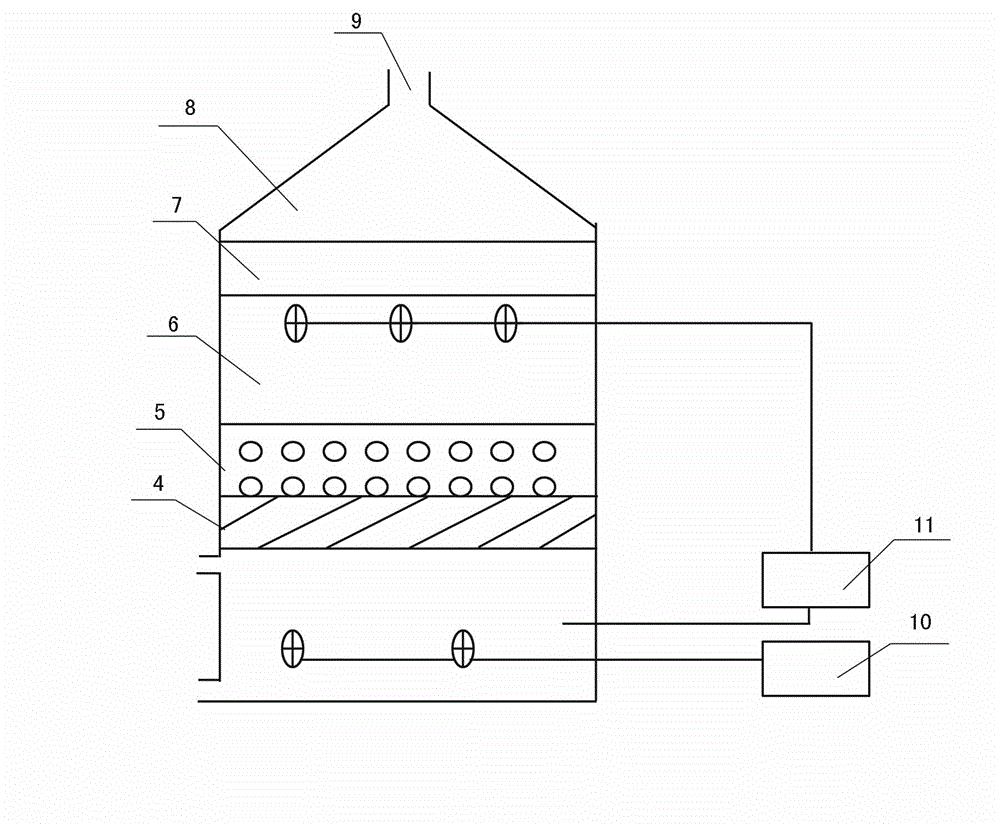

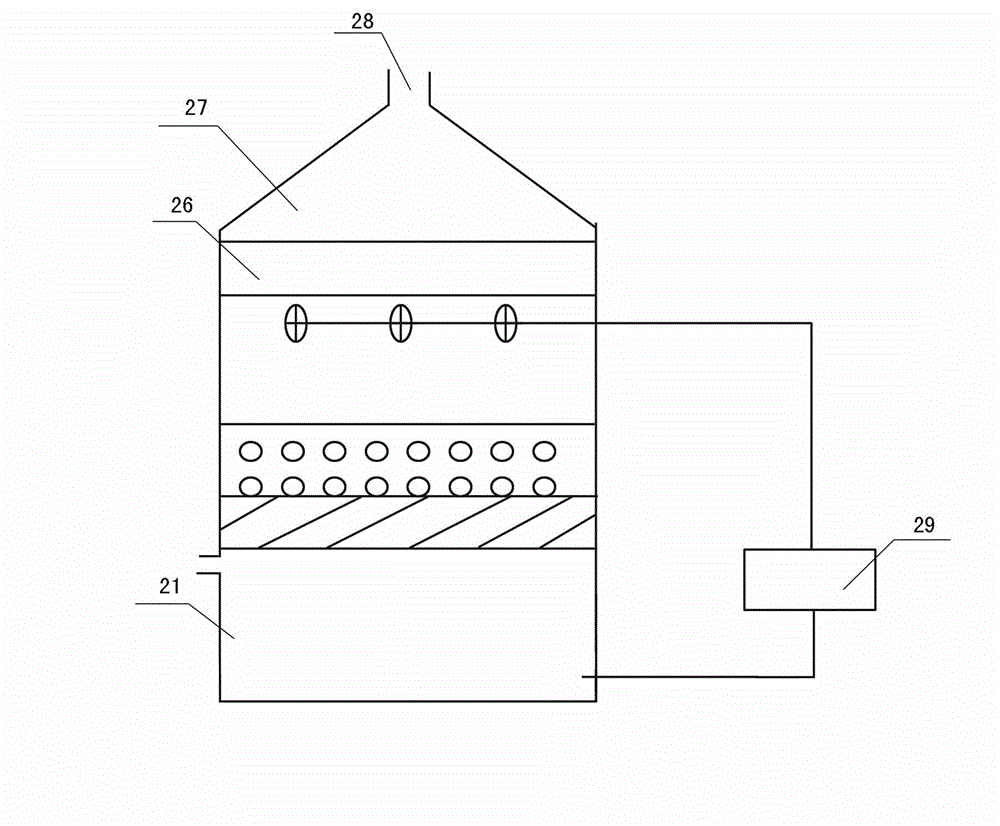

[0016] According to Figure 1, Figure 2, Figure 3, an exhaust gas comprehensive treatment device of the present invention includes an electrical control system, and also includes an exhaust gas collection and discharge system, an exhaust gas oxidation absorption-adsorption system, an exhaust gas alkalization absorption-adsorption system, and an ozone generation system. system.

[0017] The exhaust gas collection and discharge system of the present invention includes a front fan, a rear fan, an exhaust tube, an air duct, and a gate; the fan is an anticorrosive centrifugal fan made of glass fiber reinforced plastic or PP board material; the exhaust tube is made of material It is PP pipeline or carbon steel; the exhaust gas oxidation absorption-adsorption system includes an ozone generator, an oxidation absorption-adsorption tower, and a circulating water spray device 11; the exhaust gas alkalization absorption-adsorption system includes a dosing device, an alkalization absorption -A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com