Catalyst for synthesizing methyl mercaptan and preparation method of catalyst

A catalyst and a technology for methyl mercaptan are applied to the catalyst for synthesizing methyl mercaptan and the field of preparation thereof, which can solve the problem of high reaction temperature, and achieve the effects of low activity temperature and good catalyst selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

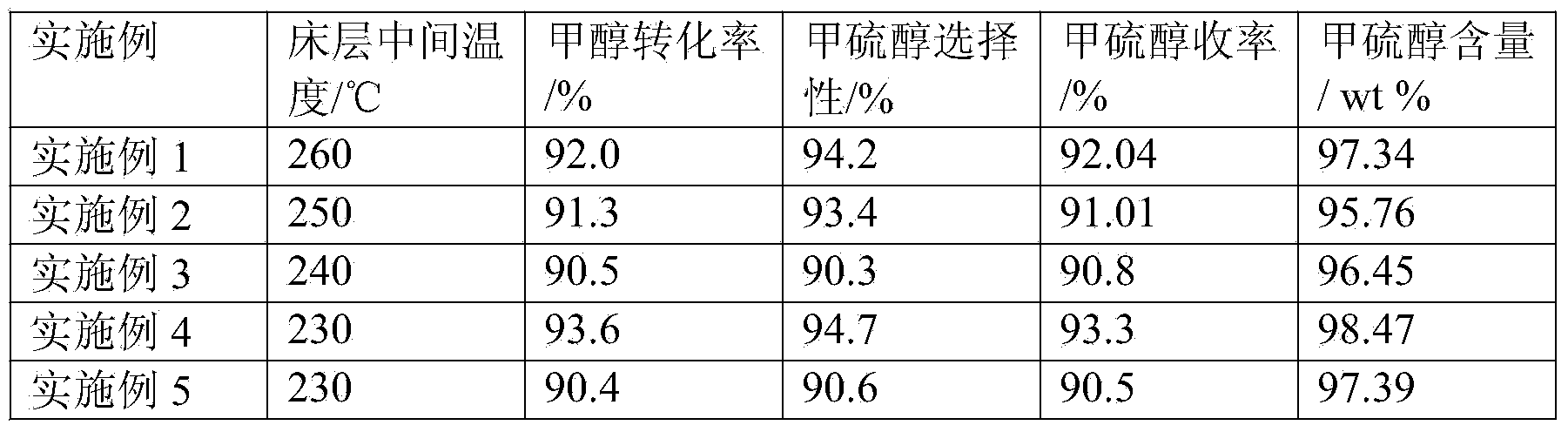

Examples

Embodiment 1

[0022] A kind of catalyst of synthesizing methyl mercaptan, by carrier gamma-Al 2 o 3 , active component Fe 2 o 3 and additive K 2 O composition, by weight percentage, γ-Al in the catalyst 2 o 3 Accounted for 93%, Fe 2 o 3 Accounting for 5%, K 2 O accounts for 2%.

[0023] The preparation method of described catalyst, concrete steps are as follows:

[0024] (1) Dissolve 0.477g of potassium hydroxide in 10ml of water, then replenish the solution to a volume equivalent to the water absorption capacity of the carrier, and evenly coat the prepared impregnating solution on 18.6g of γ-Al2O3 carrier, at 60°C Bake for 12 hours, and bake for 6 hours at 600°C in a muffle furnace;

[0025] (2) Dissolve 5.05g of ferric nitrate nonahydrate into a volume equivalent to the water absorption capacity of the carrier after step (1), then apply the solution evenly to the carrier after step (1), and finally apply the catalyst Bake at 80°C for 6 hours, and bake at 900°C in a muffle furna...

Embodiment 2

[0027] A kind of catalyst of synthesizing methyl mercaptan, by carrier gamma-Al 2 o 3 , active components ZnO and MoO 3 , Auxiliary K 2 O composition, by weight percentage, γ-Al in the catalyst 2 o 3 75%, ZnO 10%, MoO 3 Accounting for 5%, K 2 O accounts for 10%.

[0028] The preparation method of described catalyst, concrete steps are as follows:

[0029] (1) Dissolve 2.581g of sodium hydroxide in 10ml of water, then replenish the solution to a volume equivalent to the water absorption capacity of the carrier, apply the prepared impregnating solution evenly on 15g of γ-Al2O3 carrier, and place the catalyst at 120°C Bake for 6 hours, and bake for 8 hours at 500°C in a muffle furnace;

[0030] (2) Dissolve 1.350g ammonium heptamolybdate and 7.36g zinc nitrate hexahydrate together to make a volume equivalent to the water absorption capacity of the carrier after step (1), and then apply the solution evenly to the Finally, the catalyst was baked at 100°C for 8 hours, and b...

Embodiment 3

[0032] A kind of catalyst of synthesizing methyl mercaptan, by carrier gamma-Al 2 o 3 , active component Fe 2 o 3 And ZnO and NiO, additive CaO composition, by weight percentage, γ-Al in the catalyst 2 o 3 Accounted for 69%, Fe 2 o 3 10%, ZnO 5%, NiO 10%, CaO 6%.

[0033] The preparation method of described catalyst, concrete steps are as follows:

[0034](1) Dissolve 3.514g of calcium nitrate in 10ml of water, then replenish the solution to a volume equivalent to the water absorption capacity of the carrier, apply the prepared impregnating solution evenly on 15.8g of γ-Al2O3 carrier, and place the catalyst at 100°C Bake for 8 hours, and bake for 8 hours at 400°C in a muffle furnace;

[0035] (2) Dissolve 10.10g of ferric nitrate nonahydrate, 3.68g of zinc nitrate hexahydrate and 7.76g of nickel nitrate hexahydrate to form a volume equivalent to the water absorption capacity of the carrier after step (1), and then the solution is uniformly Coated on the carrier treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com