Zirconium organic frame material and preparation method and application thereof

A technology of organic framework and metal organic framework, which is applied in the field of new functionalized UiO-66 system zirconium organic framework catalyst material and its preparation, can solve the problems of performance degradation, inability to decompose water, attenuation, etc., and achieve excellent performance, stable structure, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Synthesis of ligand 2,5-dimethylsulfide terephthalic acid

[0035]Weigh 57.5mg of 2,5-dimercaptoterephthalic acid in a 50ml single-necked flask, then add 20.0ml of acetone, stir and then add 207mg of K 2 CO 3 , and finally add 0.5ml CH dropwise while stirring 3 I liquid. Stir until the color changes from orange to thick yellow-white, and spin evaporate to obtain a white solid, then dissolve the white solid in deionized water, place in an ice-water bath, add concentrated hydrochloric acid dropwise to pH = 1, a large amount of yellow precipitate appears, and finally extract A yellow solid was obtained by filtration, and washed with a large amount of deionized water until pH = 7. The obtained yellow sample was dried in a vacuum oven at 60°C.

[0036] The proton nuclear magnetic spectrum data of the obtained 2,5-dimethyl sulfide terephthalic acid are as follows:

[0037] 1 H NMR (400MHz, deuterated DMSO): 7.74(s, 2H, CHAr), 2.40(s, 6H, CH 3 )

[0038] The hydrog...

Embodiment 2

[0043] (1) Synthesis of ligand 2,5-dimethylsulfide terephthalic acid

[0044] Weigh 57.5mg of 2,5-dimercaptoterephthalic acid in a 50ml single-necked flask, then add 20.0ml of acetone, stir and then add 207mg of K 2 CO 3 , and finally add 0.5ml CH dropwise while stirring 3 I liquid. Stir until the color changes from orange to thick yellow-white, and spin evaporate to obtain a white solid, then dissolve the white solid in deionized water, place in an ice-water bath and add concentrated hydrochloric acid dropwise to PH = 1, a large amount of yellow precipitate appears, and finally pump A yellow solid was obtained by filtration, and washed with a large amount of deionized water until pH = 7. The obtained yellow sample was dried in a vacuum oven at 60°C.

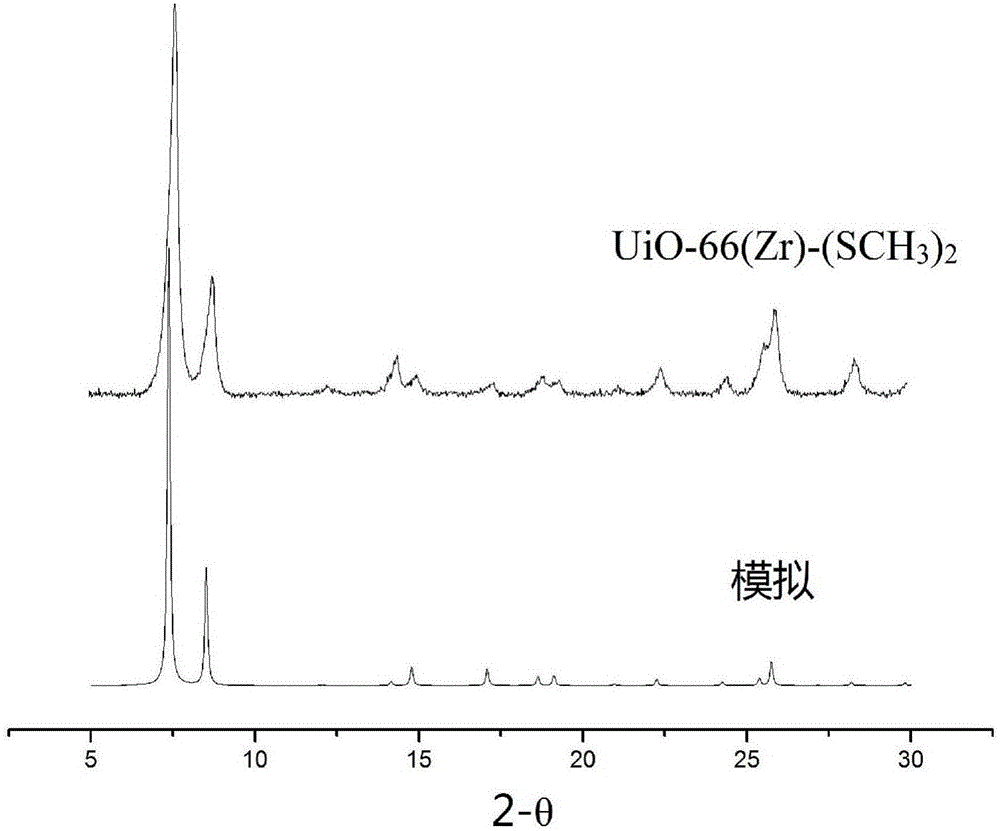

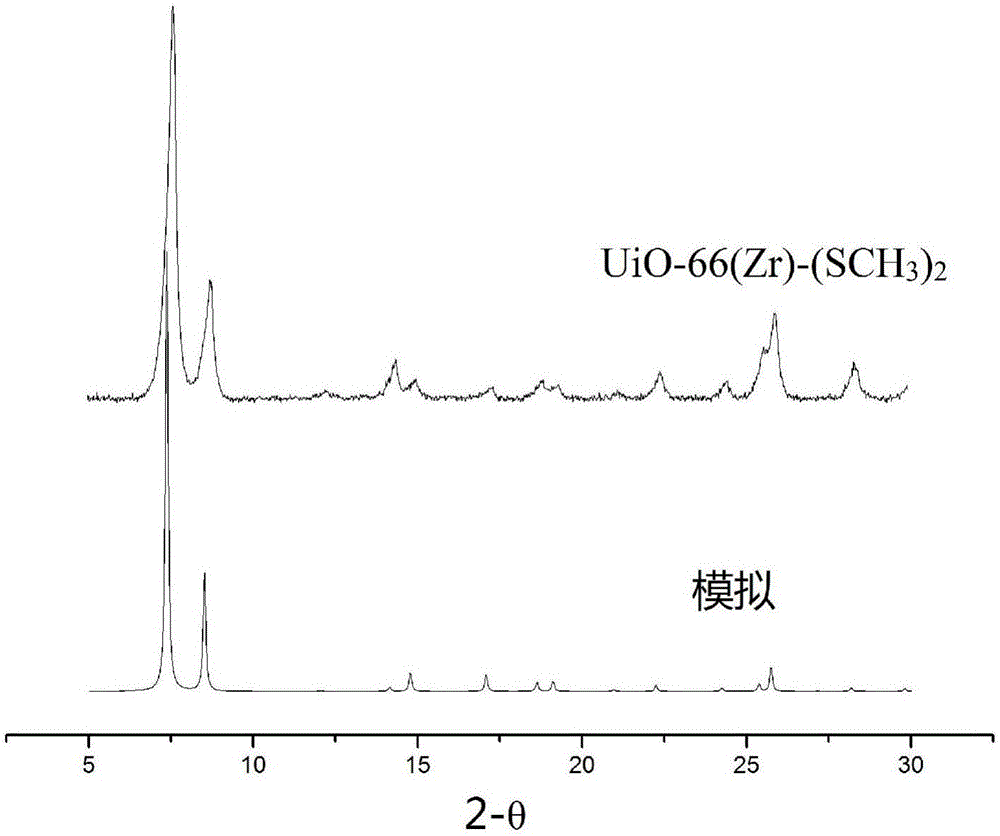

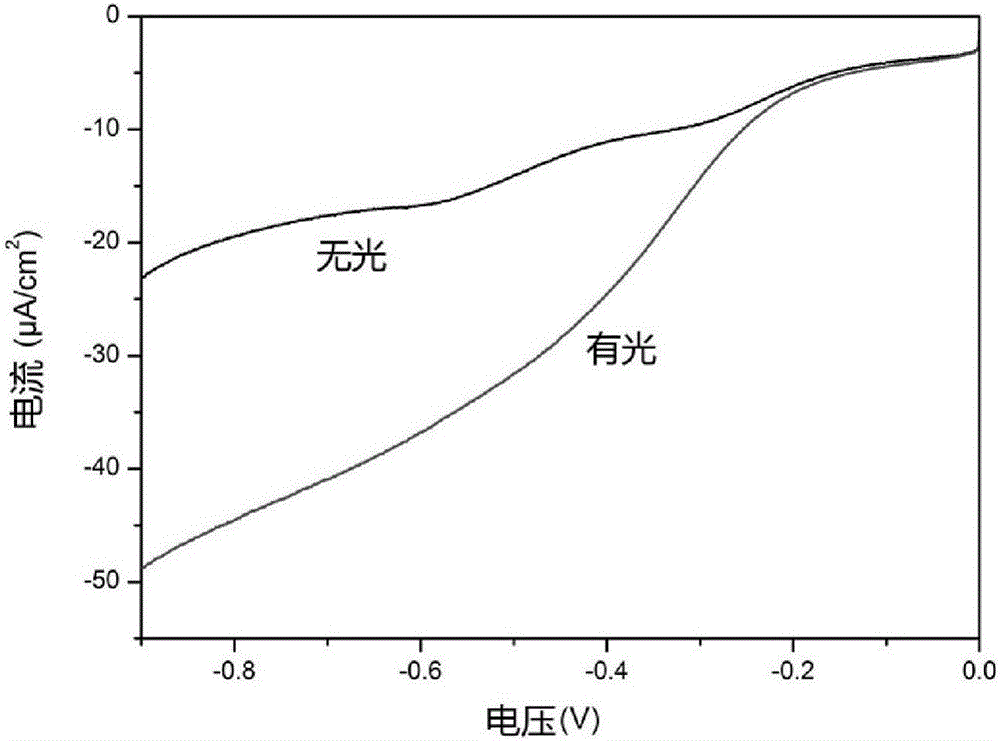

[0045] (2)UiO-66(Zr)-(SCH 3 ) 2 preparation of

[0046] Take 58.25mg of zirconium tetrachloride, 1.5ml of glacial acetic acid, and 15ml of DMF in a 50ml flask, and ultrasonically disperse until the zirconium tetrachloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com