Method for oxidizing dimethyl sulfide

A technology of dimethyl sulfide and titanium dioxide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as environmental pollution by operating conditions, and achieve complex production processes, improved ozone effective utilization, Beneficial to industrial production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

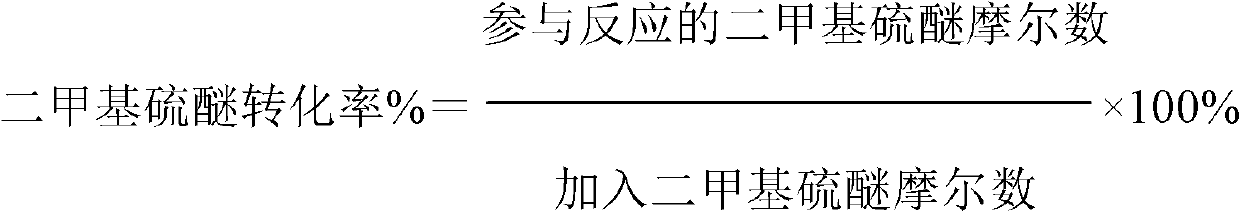

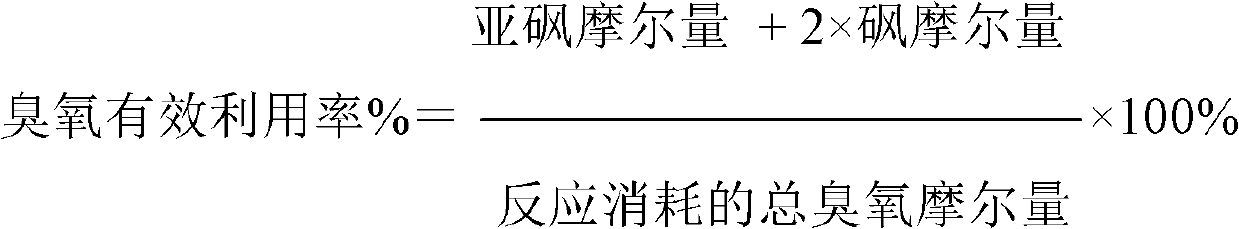

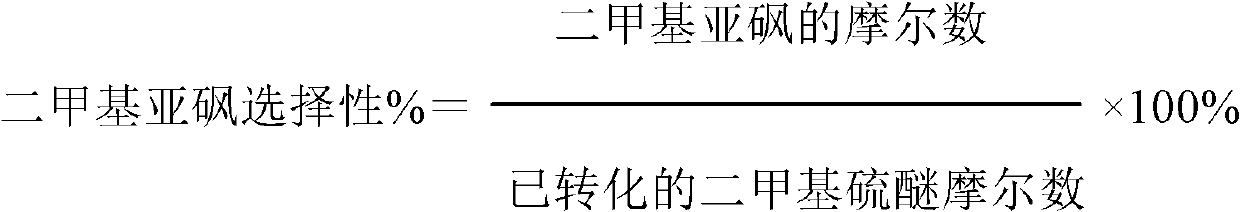

Embodiment 1

[0040] At a temperature of 60°C and a pressure of 0.5 MPa, with ozone (15% by volume, the rest being oxygen) as an oxidant, dimethyl sulfide, ozone and solvent acetone are reacted in a molar ratio of 1:1:1 . The results of the reaction for 2 hours are as follows: the conversion rate of dimethyl sulfide is 44%; the effective utilization rate of ozone is 58%; the selectivity of dimethyl sulfoxide is 88%; the selectivity of dimethyl sulfone is 11%.

Embodiment 2

[0042] At a temperature of 20°C and a pressure of 1.5 MPa, with ozone (30% by volume, the rest being air) as an oxidant, dimethyl sulfide, ozone and solvent acetic acid are reacted in a molar ratio of 1:1:5 . The results of the reaction for 5 hours are as follows: the conversion rate of dimethyl sulfide is 53%; the effective utilization rate of ozone is 61%; the selectivity of dimethyl sulfoxide is 73%; the selectivity of dimethyl sulfone is 25%.

Embodiment 3

[0044] At a temperature of 80°C and a pressure of 0.2 MPa, with ozone (5% by volume, the rest being oxygen) as an oxidant, dimethyl sulfide, ozone and solvent methanol are reacted in a molar ratio of 1:2:10 . The results of the reaction for 2 hours are as follows: the conversion rate of dimethyl sulfide is 57%; the effective utilization rate of ozone is 48%; the selectivity of dimethyl sulfoxide is 78%; the selectivity of dimethyl sulfone is 21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com