Gas purification method of low concentration organic compound

A technology for purification of organic compounds and gases, applied in chemical instruments and methods, separation methods, catalyst carriers, etc., can solve problems such as air pollution, odor, and inability to effectively purify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

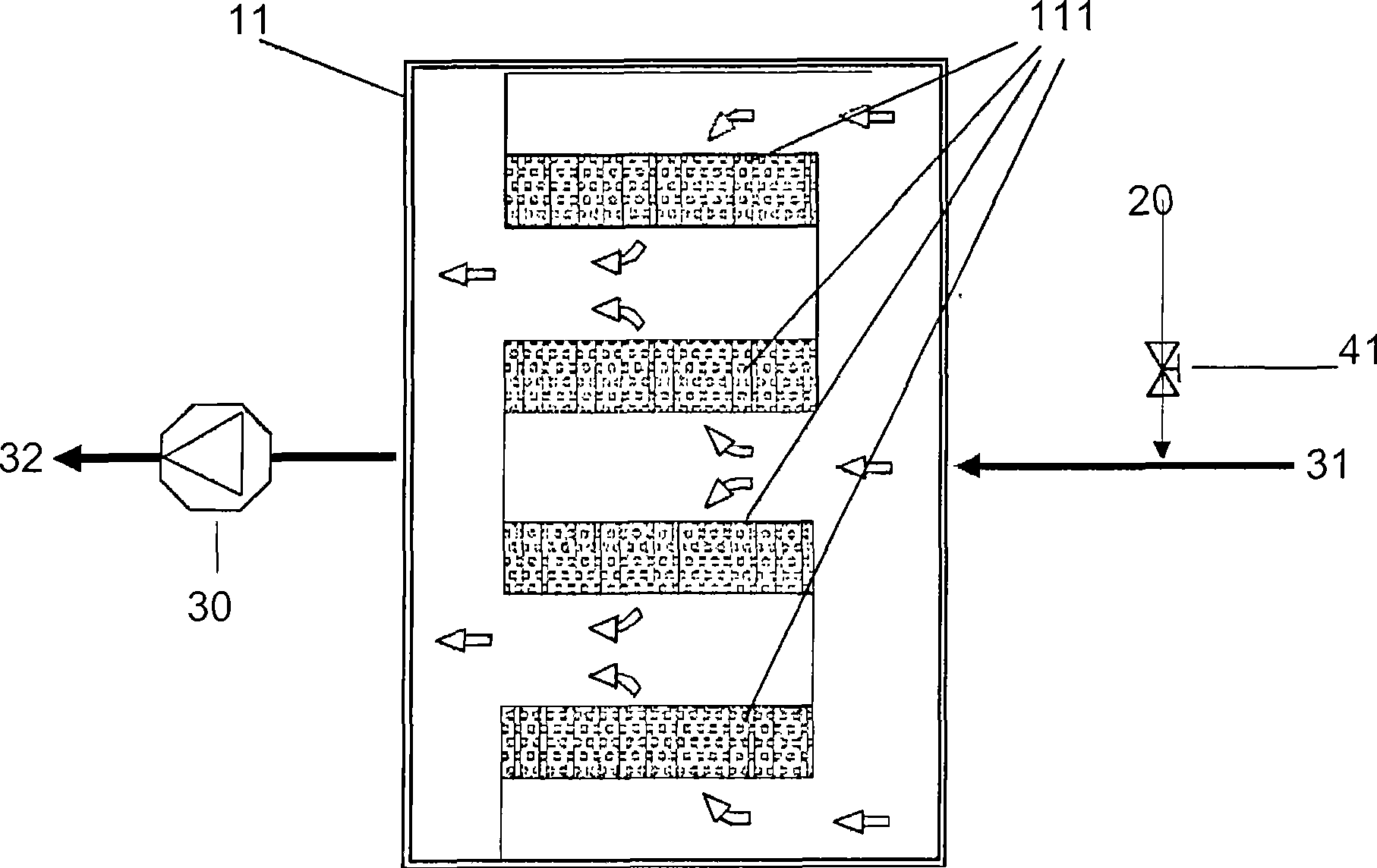

[0058] figure 1 It is a schematic diagram of a preferred embodiment of the gas purification device for low-concentration organic compounds in the air of the present invention. The device comprises a catalyst adsorption unit 11, which is filled with a catalyst adsorption material 111, and it is composed of a catalyst carrier and a catalyst, and the catalyst carrier is selected from activated carbon, zeolite, aluminum oxide, other porous substances or mixtures thereof; The active portion of the catalyst is N-orbit metal, which is selected from Mn, Fe, Co, Ni, Cu, Ag, Pb or Zn; The downstream end, which can pump the air to be treated to the catalyst adsorption unit 11 through the catalyst adsorption material 111; a control valve 41, which can control whether ozone needs to enter the catalyst adsorption unit 11 and the catalyst adsorption material 111; and an ozone The generating unit 20 can provide ozone to the catalyst adsorption unit 11 and the catalyst adsorption material 111...

Embodiment 2

[0061] Use the device described in embodiment 1, open fan 30, close valve 41, the gas of the low-concentration organic compound that can be processed in air inlet 31 can be introduced into catalyst adsorption unit 11 and catalyst adsorption material 111 through fan 30, carry out chemical Adsorption reaction, the clean gas after adsorption flows through a gas outlet 32 to be discharged. Can choose to open valve 41 simultaneously, import the ozone that ozone generation unit 20 produces and regulate the concentration of ozone supply or generation, make the catalyst adsorption material 111 in the catalyst adsorption unit 11 that has carried out chemical adsorption before can carry out low temperature redox or and decomposition reaction, so as to prolong the service life and treatment efficiency of the catalyst adsorption material 111 filled inside the catalyst adsorption unit 11 , and the resulting net gas is discharged from the gas outlet 32 .

[0062] After the catalyst adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com