Method for melt-spinning, drawing, and winding a multifilament thread and a device for performing the method

A fully drawn yarn, melt spinning technology, applied in the direction of draw spinning, textile and papermaking, rayon physical therapy, etc., can solve problems such as large tensile force, achieve compact stretching and relaxation, and improve the tightness of the yarn. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

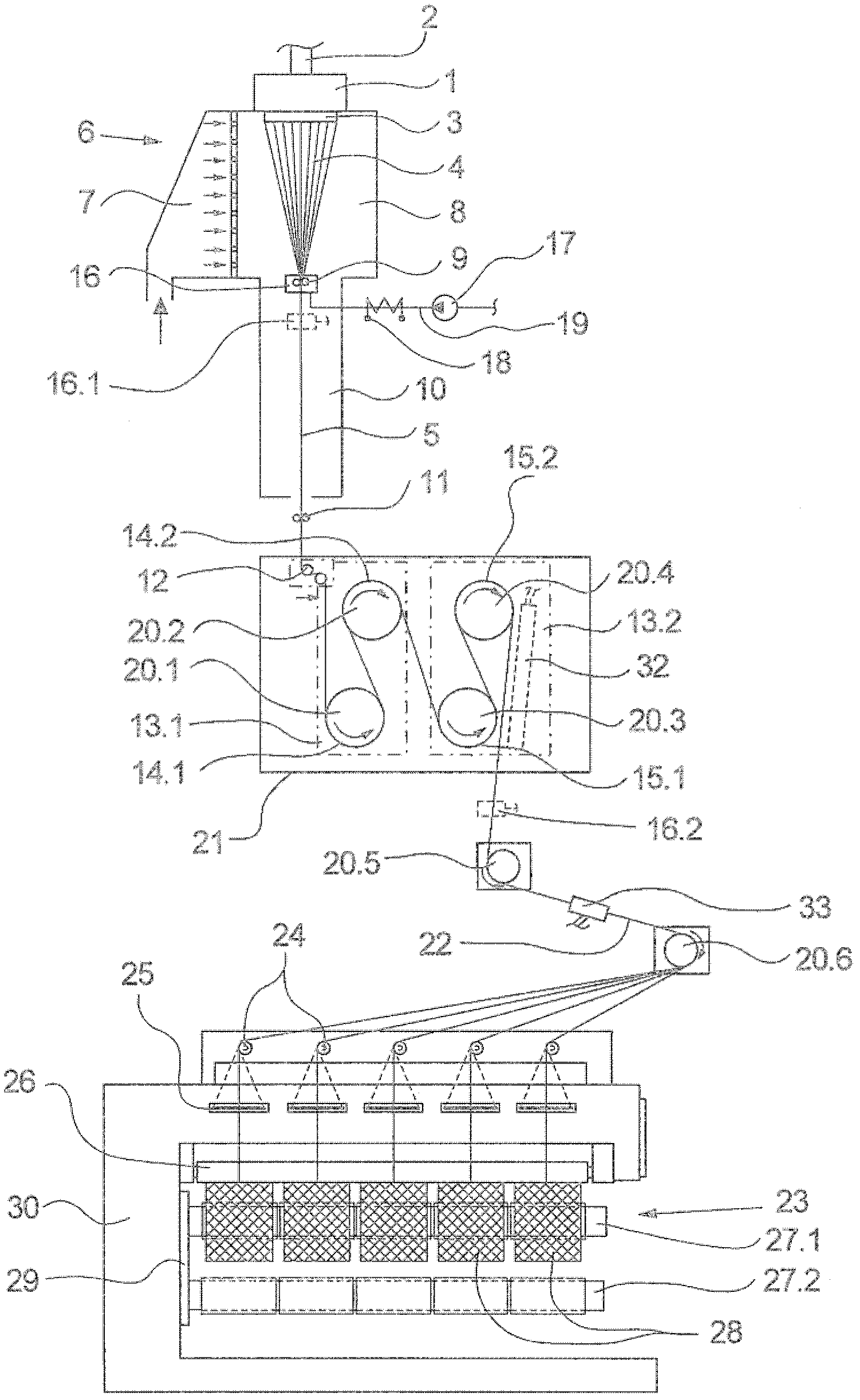

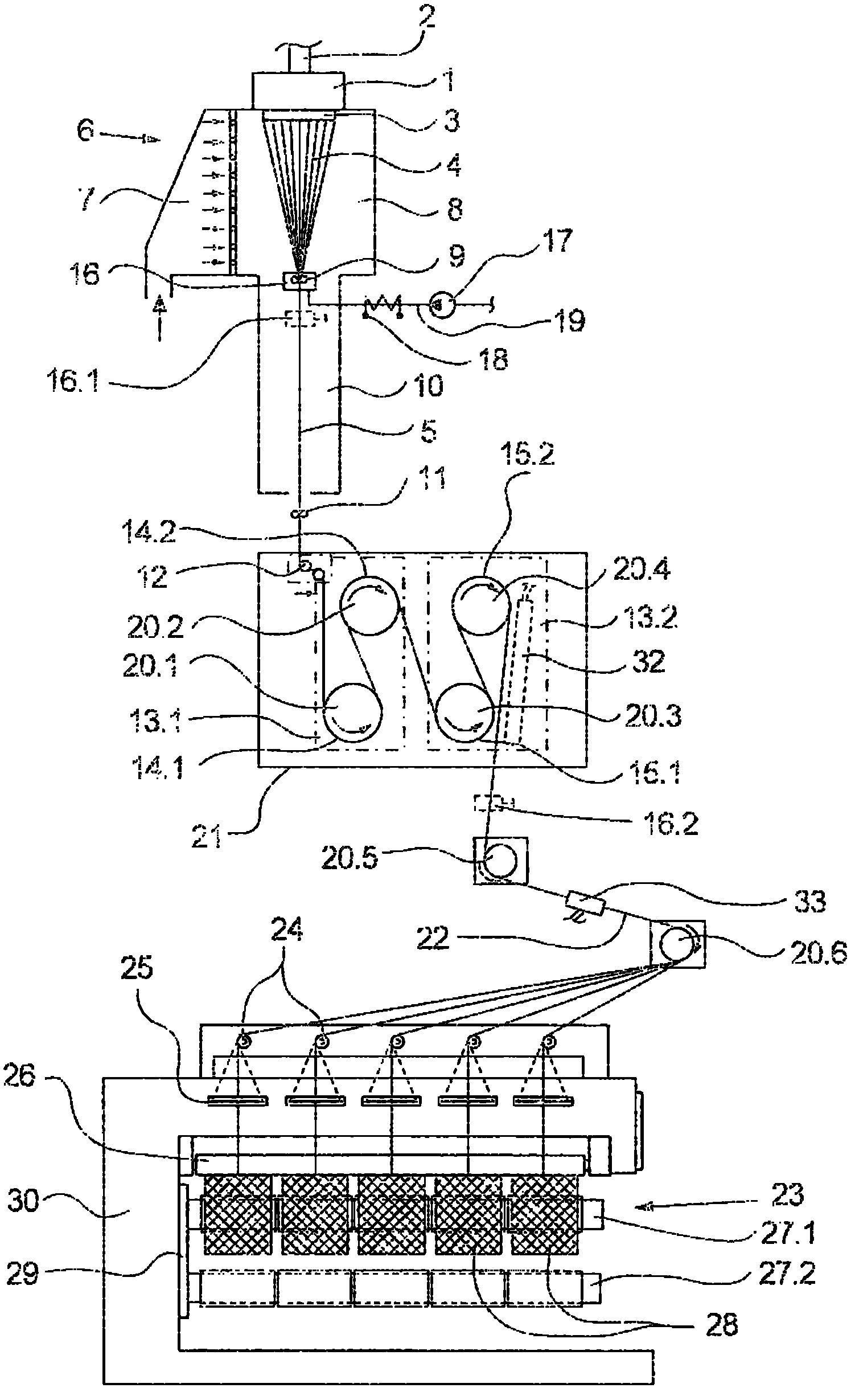

[0032] figure 1 An embodiment of the device according to the invention is shown for carrying out the method for manufacturing a fully drawn yarn according to the invention.

[0033] In order to melt-spin the multifilament, a heatable spinning box 1 is provided, which has a spinning nozzle 3 on its lower side and a melt inlet 2 on its upper side, the spinning nozzle with multiple nozzles Silk hole. The melt feed 2 is connected to a melt source not shown here, such as an extruder. Other components for guiding and conveying the melt can be provided in the spinning box 1, which will not be described in detail here.

[0034] The spinning box 1 has a plurality of spinning nozzles 3 on its lower side so as to simultaneously spin a plurality of threads in parallel side by side. The spinning box 1 is oriented transversely to the plane of the figure, thus in figure 1 Only one of the spinning nozzles 3 is visible. Therefore, the downstream devices and assemblies are explained in detail w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com