Combined anaerobic fermentation process for organic solid wastes

A technology of anaerobic fermentation and organic solids, applied in the direction of organic fertilizer, waste fuel, bio-organic part treatment, etc., can solve the problems of reducing the inhibition of fermentation products, obvious inhibition factors of single material, waste of liquid humus fertilizer, etc., to achieve Good scale effect, friendly interface, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

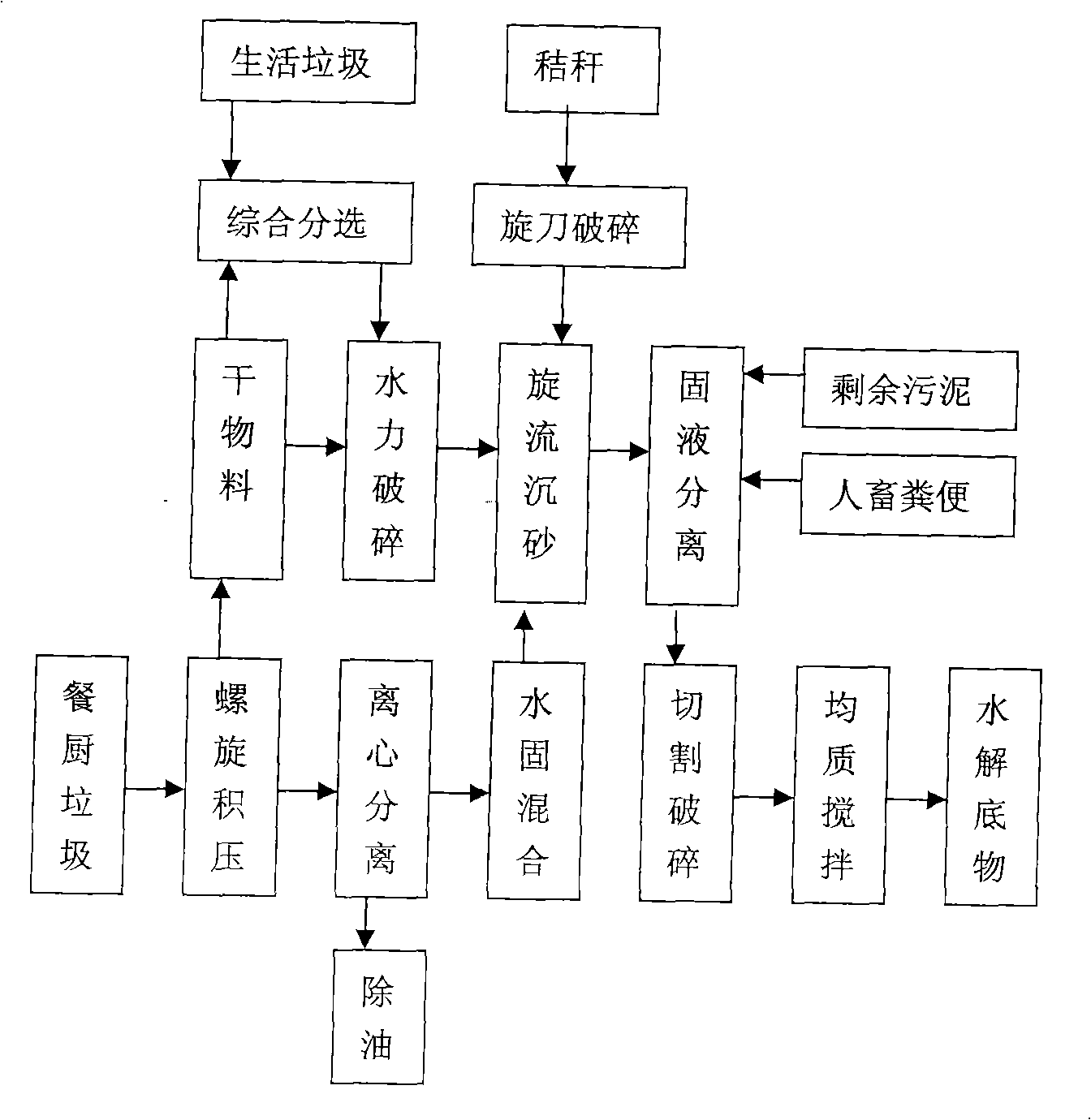

[0029] Domestic waste is first broken into materials below 10mm, and then comprehensively sorted. The comprehensive sorting process mainly includes combined sorting units such as magnetic separation, air separation, and density separation. The material with a particle size of less than 5mm is obtained, and then enters the suspension grit settling unit. After the grit settling removes impurities, it enters the solid-liquid separation unit, and finally is crushed by the cutting pump and then enters the stirring homogeneous tank.

[0030] The feces and excess sludge are collected and transported by the transport vehicle to the solid-liquid separation, and solid foreign objects such as paper, plastic, and stone are removed to obtain slurry materials, which are then transported to the mixing and homogenizing tank through closed pipelines.

[0031] The food waste is dehydrated and deoiled by screw extrusion and separated into dry matter and oil-water mixture. The dry matter is crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com