Waterproof and flame-retarded PVC (polyvinyl chloride) cable material for data cable and preparation method thereof

A technology for data cables and cable materials, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the product index performance is difficult to meet the requirements, and achieve improved stability and service life, good mechanical stability, and electrical performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

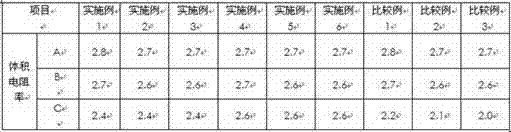

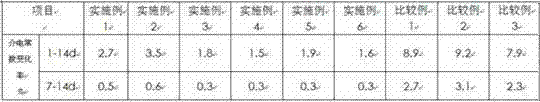

Examples

Embodiment 1

[0024] SG3 type PVC resin: 100 parts, TOTM: 35 parts, commercially available calcium zinc stabilizer: 5 parts, antimony trioxide: 8 parts, polyethylene wax: 0.3 parts, stearic acid: 0.2 parts, bisphenol A: 0.2 parts Parts, water resistance modifier: 12 parts (of which nano-barium sulfate: 2 parts, calcined kaolin: 7.5 parts, nano-silica: 2 parts, vinyl tris (β-methoxyethoxy) silane: 0.5 parts) .

Embodiment 2

[0026] SG3 type PVC resin: 100 parts, TOTM: 32 parts, commercially available calcium zinc stabilizer: 5 parts, antimony trioxide: 8 parts, polyethylene wax: 0.2 parts, stearic acid: 0.2 parts, bisphenol A: 0.2 parts parts, water resistance modifier: 10 parts (of which nano-barium sulfate: 2 parts, calcined kaolin: 5.7 parts, nano-silica: 2 parts, vinyltrimethoxysilane: 0.3 parts).

Embodiment 3

[0028] SG3 type PVC resin: 100 parts, TOTM: 38 parts, commercially available calcium zinc stabilizer: 5 parts, antimony trioxide: 10 parts, polyethylene wax: 0.5 parts, bisphenol A: 0.2 parts, water resistance modifier: 8 parts (of which nano-barium sulfate: 2 parts, calcined kaolin: 3.7 parts, nano-silica: 2 parts, γ-glycidyl etheroxypropyl trimethoxysilane: 0.3 parts).

[0029] The commercially available calcium-zinc stabilizer described in Examples 1-3 is the 519A calcium-zinc stabilizer suitable for wires and cables produced by Jiangxi Hongyuan Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com