Fixing device of leading-out cable of pressure sensor

A technology of pressure sensor and lead-out cable, used in measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as damage measurement and failure, and achieve the effect of ensuring normal use and meeting industrial needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

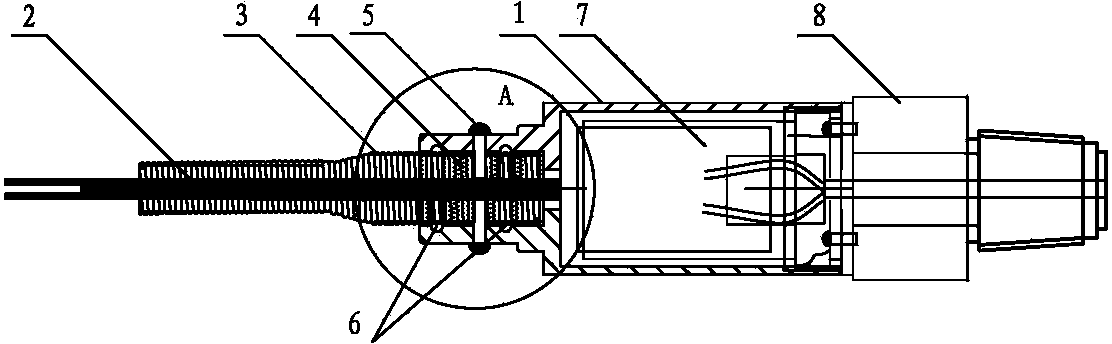

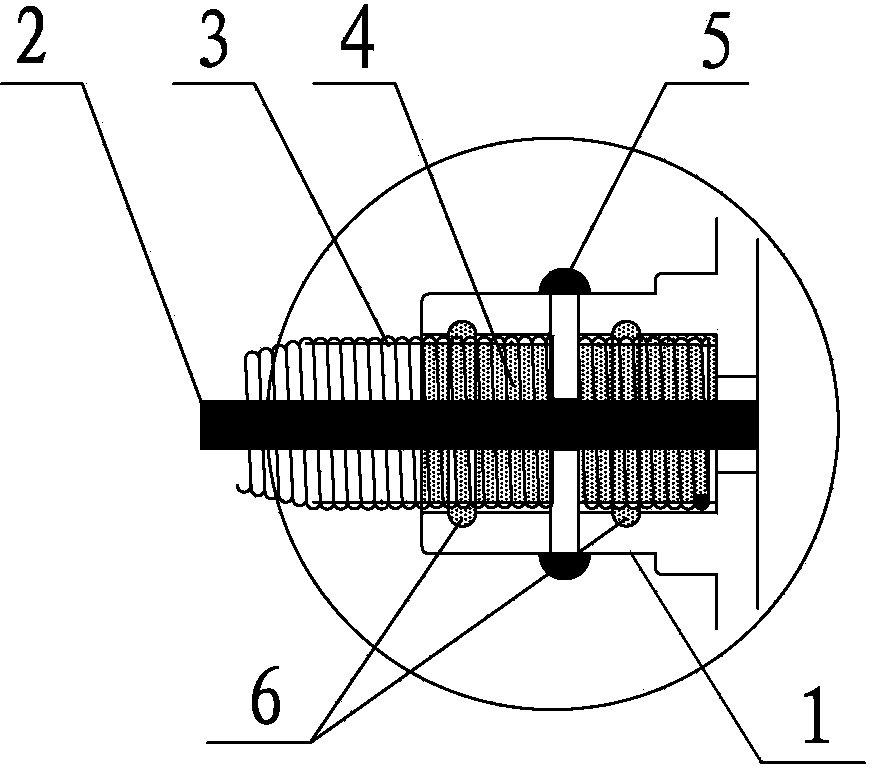

[0015] like figure 1 , 2 As shown, a pressure sensor leading cable fixing device includes a stainless steel cover 1, leading cable 2, wire protection spring 3, potting glue 4, the leading cable 2 is covered with the protective wire spring 3, the outer cover 1 and the leading cable 2 is filled with epoxy resin potting glue 4, and there are fastening spring screws 5 between the part filled with potting glue 4 in the outer cover 1 and the lead-out cable 2, and there are 4 fastening spring screws 5, which are uniform and symmetrical Distributed on the outer cover 1, the fastening spring screws 5 pass through the outer cover 1, the wire protection spring 3, and the potting glue 4, and then close to the lead-out cable 2, and on the inner wall of the outer cover 1 filled with the potting glue 4, set the fastening spring potting glue The ring groove 6 is 2 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com