Interface structure of micro-fluidic chip, and manufacturing method and application thereof

A microfluidic chip and interface structure technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc. Improve overall strength, improve tightness, and ensure the effect of strength and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

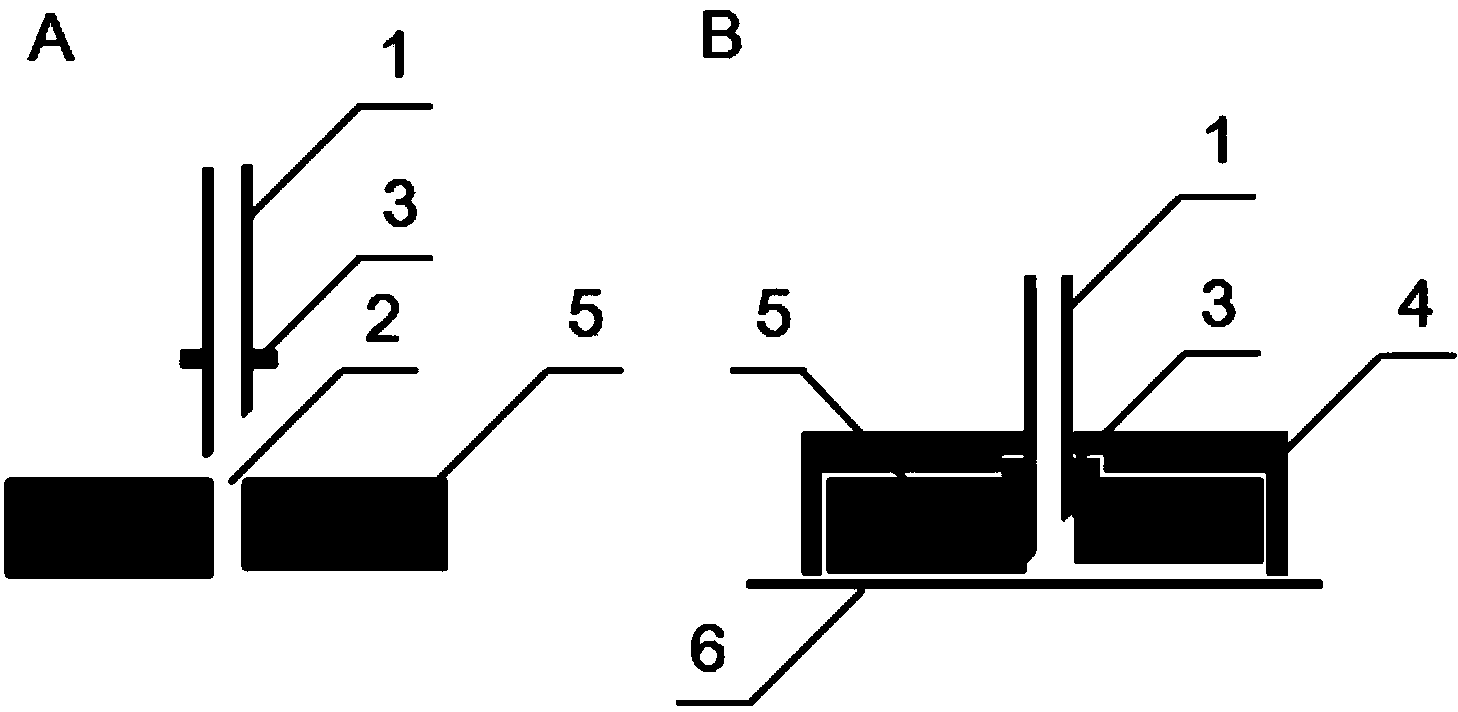

Method used

Image

Examples

Embodiment 1

[0041] In this example, the uncured PDMS is prepared into a mixed solution according to the ratio of monomer and curing agent 10:1 (v:v), poured into the mold, and cured at 80°C for 2 hours (or cured at 100°C 15min), forming a microfluidic chip with a thickness of about 4-6mm, one of which has a channel surface.

[0042] Take out the microfluidic chip from the mold, use a puncher with an inner diameter of 0.5 mm and an outer diameter of 0.81 mm to punch a circular through hole connecting the outside world and the channel on the back of the channel surface, as the microfluidic channel inlet / outlet, and use For sample inflow or product or reaction waste outflow.

[0043] After drilling, take a PE drainage tube with an outer diameter of 1 mm, apply a small amount of uncured Dow Coning 3145 series silica gel on its port, and then insert the drainage tube into the microfluidic channel inlet / outlet pre-punched on the microfluidic chip The two form an interference fit, and the drain...

Embodiment 2

[0047] In this example, PMMA is melted at 240-270°C, poured into a mold with a temperature of 35-70°C, and after it is solidified, a microfluidic chip with a thickness of about 4-6mm is formed, one side of which has a channel noodle.

[0048] Take out the microfluidic chip from the mold, use a puncher with an inner diameter of 0.5 mm and an outer diameter of 0.81 mm to punch a circular through hole connecting the outside world and the channel on the back of the channel surface, as the microfluidic channel inlet / outlet, and use For sample inflow or product or reaction waste outflow.

[0049] After drilling, take a PEEK drainage tube with an outer diameter of 1 mm, apply a small amount of uncured Dow Coning 3145 series silica gel on its port, and then insert the drainage tube into the microfluidic channel inlet / outlet pre-punched on the microfluidic chip The two form an interference fit, and the drainage tube is firmly fixed in the inlet / outlet of the microfluidic channel.

[...

Embodiment 3

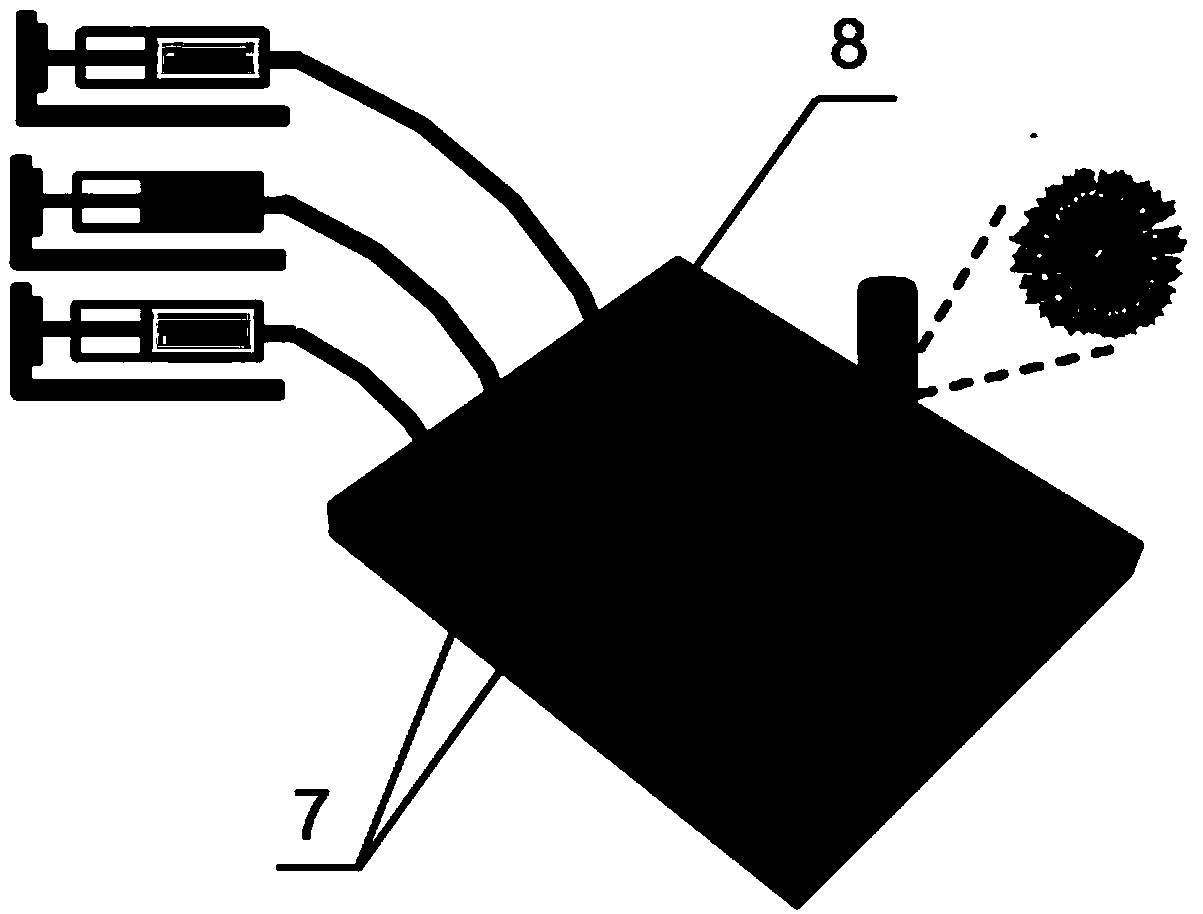

[0053] In this example, the interface structure of the microfluidic chip produced in Example 1 is used in the high-throughput synthesis of nanoparticles. Please refer to figure 2 , the interface structure of the water phase inlet 7 and the organic phase inlet 8 of the microfluidic device of this embodiment is made according to the method described in Example 1, and the sealing of the microfluidic device is completed. Pass into pure water from water phase inlet 7, pass into 2wt% PLGA solution (ie polylactic acid-glycolic acid copolymer solution, solvent is N,N-dimethylformamide) from organic phase inlet 8, water phase and organic phase The flow rate ratio of the three inlets can be adjusted as needed, and the flow rate ratio of the three inlets is preferably 200 (water phase): 10 (organic phase): 200 (water phase). Due to the extremely high flow rate ratio, the liquid is strongly mixed at the inlet, so that PLGA is rapidly precipitated from the solution, so that PLGA nanopart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com