Slowly-sinking puffed compound feed for misgurnus anguillicaudatus and production process thereof

A technology of extruded compound feed and production technology, which is applied in animal feed, animal feed, food science, etc., can solve the problems of slow growth of loach, and achieve the effects of improving healthy growth, improving utilization rate, and increasing growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

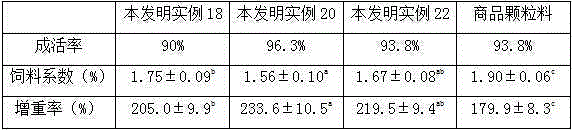

Examples

Embodiment 1

[0035] A slow-settling extruded compound feed for loach, comprising the following raw materials in parts by weight:

[0036] 5 parts of fish meal, 3 parts of pork meal, 10 parts of soybean meal, 3 parts of peanut meal, 5 parts of cotton meal, 5 parts of rapeseed meal, 3 parts of corn DDGS, 5 parts of rice bran, 15 parts of flour, 2 parts of soybean oil, calcium dihydrogen phosphate 1 part, 2 parts of bentonite, 0.2 part of vitamin premix, 1 part of trace element premix, 0.05 part of choline chloride, 0.05 part of antioxidant, 0.05 part of antifungal agent.

Embodiment 2

[0038] A slow-settling extruded compound feed for loach, comprising the following raw materials in parts by weight:

[0039]10 parts of fish meal, 10 parts of pork meal, 25 parts of soybean meal, 8 parts of peanut meal, 15 parts of cotton meal, 20 parts of rapeseed meal, 10 parts of corn DDGS, 15 parts of rice bran, 20 parts of flour, 4 parts of soybean oil, calcium dihydrogen phosphate 3 parts, 5 parts of bentonite, 1.5 parts of vitamin premix, 3 parts of trace element premix, 0.5 part of choline chloride, 0.1 part of antioxidant, 0.1 part of antifungal agent.

Embodiment 3

[0041] A slow-settling extruded compound feed for loach, comprising the following raw materials in parts by weight:

[0042] 7.5 parts of fish meal, 6.5 parts of pork meal, 17.5 parts of soybean meal, 5.5 parts of peanut meal, 10 parts of cotton meal, 12.5 parts of rapeseed meal, 6.5 parts of corn DDGS, 10 parts of rice bran, 17.5 parts of flour, 3 parts of soybean oil, calcium dihydrogen phosphate 2 parts, 3.5 parts of bentonite, 0.85 parts of vitamin premix, 2 parts of trace element premix, 0.3 part of choline chloride, 0.075 part of antioxidant, 0.075 part of antifungal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com